‘World-class’ machine to debut at expo

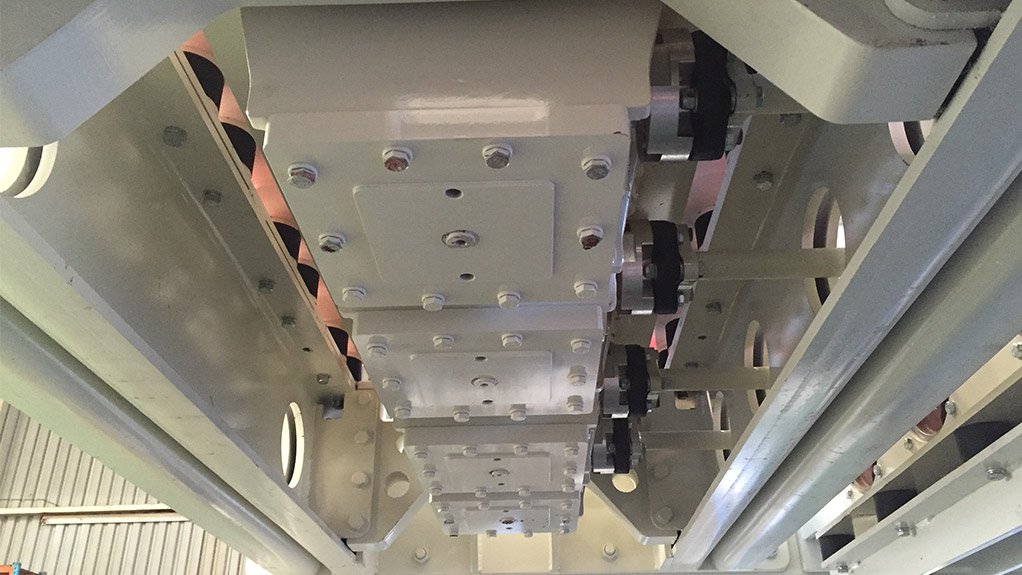

BUILDING BLOCKS The Ultra 3000 is comprised of a number of different components – combining the latest technologies from around the world

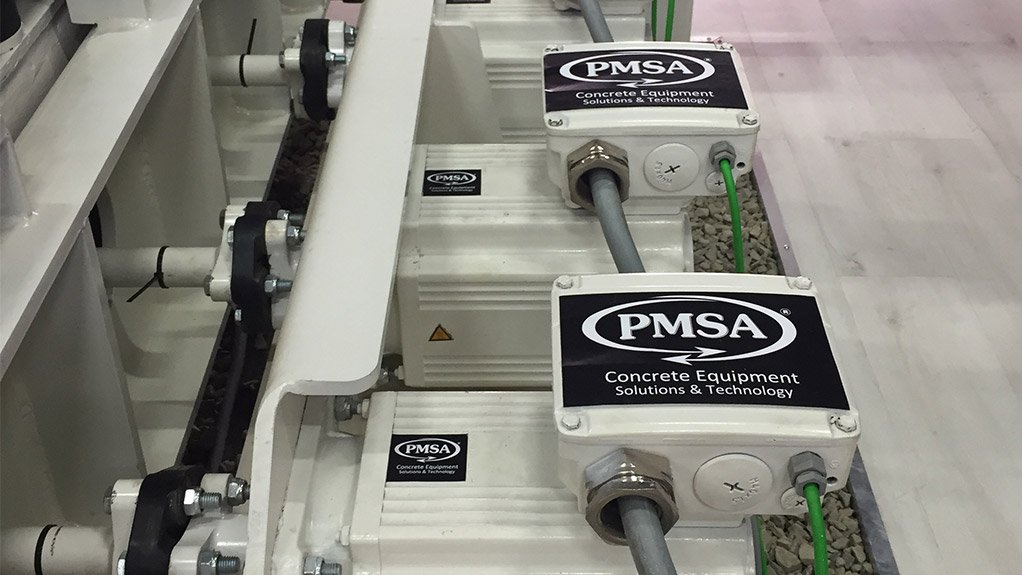

ENVIRONMENT FRIENDLY The Ultra 3000’s servo controlled four motor vibrating system enables the machine to generate enormous power, using less energy

Concrete products machinery manufacturer Pan Mixers South Africa (PMSA) has designed the “world’s best” concrete-product manufacturing machine, which will debut at this year’s bauma CONEXPO AFRICA, PMSA joint MD Walter Ebeling reveals exclusively to Engineering News.

The Ultra 3000 is an advanced, completely new design of a concrete-product machine that manufactures bricks, maxi bricks, hollow bricks and paving.

With a production board size of 1.4 m × 1 m, it boasts a high production capacity of concrete products ranging from 35 mm to 500 mm in thickness. The Ultra 3000 can manufacture 250 000 bricks in one operation when they are produced on end, compared with its predecessor that could produce only between 140 000 and 160 000 bricks.

The Ultra 3000 comprises several different components, combining the latest global technologies, subsequently “allowing it to make the fastest, most stable and best-quality concrete products that any machine in the world can make – we are very proud of this machine”, says Ebeling.

One of the most notable components is the servo-controlled, four-motor vibrating system, which enables the machine to have independent variable frequency of vibration and independent variable force of vibration. Manipulating the independent force and frequency of vibrations is the element that enables the user to tailor the machine to produce the desired product from the machine’s range.

The machine’s energy consumption, compared with a conventional two-motor system, is much less because the motors are not stopping and starting during operation, but move continuously. “This is quite a technological advancement because the energy that is created when the motors slow down is controlled and reintroduced, reducing the machine’s electricity consumption and making it much more environment friendly. The Ultra 3000 generates enormous power, but uses very little energy to do so.”

The “innovative” vibration system, coupled with other features from the machine, will allow for a high compaction of products. “We believe that this will enable clients to produce high-quality products of a dense quality, thereby reducing the amount of cement required and, ultimately, leading to a more profitable product and a higher production capacity.”

Further, a high-specification hydraulic system component controls the machine functions, making the machine as fast as possible.

The machine’s components are integrated using a closed-loop programmable logic controller (PLC) from automation systems provider Beckhoff.

The PLC, programmed by PMSA, is aware of and communicates with every component and its movements. Owing to the high processing speed of Beckhoff’s technology, the PLC responds to signals and issues quickly, resulting in a fast, accurate and efficient machine.

The controller is equipped with a dual modular redundancy communication system for all the sensors on the machine. Therefore, if one cable becomes faulty, it can communicate with these sensors through the second.

“As the largest company in our field, it is important for us to attend bauma, and we see it as the ideal platform to launch our new product,” says Ebeling.

The company has attended both previous versions of the show held in 2013 and 2015. PMSA’s stand will be located in Hall 5, where a number of the company’s products, and its suppliers’ products, will also be on display.

Proseal, a new sealing product that can be applied to concrete in its wet or semi-cured state to seal a surface; self-loading mixers; and production boards producer MyWood’s composite palette, a new production board that creates a smooth, hard surface for the longevity of products, will also be on show, highlights PMSA marketing and sales manager Quintin Booysen.

All 15 of the company’s European suppliers have confirmed that there will be a representative at the event, with Booysen noting that these representatives are typically owners of the respective businesses.

Moreover, PMSA will demonstrate the capabilities of several machines in the demarcated arena, including those of vehicles, dumpers and mixer trucks manufacturer and supplier Fiori’s self-loading 4 × 24 concrete mixing truck, and grinding and maintenance systems manufacturer and supplier HTC’s deuretic floor grinding and polishing machine.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation