Sanral lauds benefits, intricacies of recently completed Musina ring road project

Hand sculpture

Photo by Creamer Media's Tasneem Bulbulia

Helping hands at Nancefield interchange

Photo by Creamer Media's Tasneem Bulbulia

Hennie Kotze explains how the cuttings over the old copper mine were managed

Photo by Creamer Media's Tasneem Bulbulia

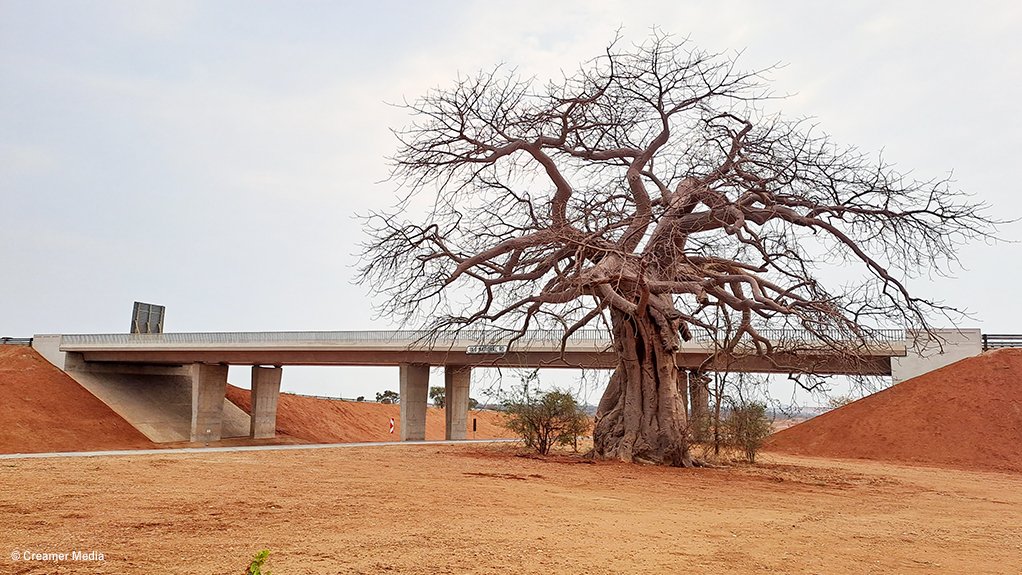

The road had to be designed around baobab those that could not be moved

Photo by Creamer Media's Tasneem Bulbulia

The new landfill and the rehabilitated site

Photo by Creamer Media's Tasneem Bulbulia

One of the narrative structure

Photo by Creamer Media's Tasneem Bulbulia

A media visit to the South African National Roads Agency Limited’s (Sanral's) recently completed N1 Musina ring road, in Limpopo, afforded the road parastatal the opportunity to expound on the benefits, challenges and complex processes involved in the almost 20-year-long project coming to fruition.

The R700-million project entailed the construction of about 8 km of greenfield single carriageway freeway to form the western ring road around the town of Musina.

The alignment deviates from the existing N1 Section 29 alignment just south of Musina, and ties back into the existing alignment just north of the town, forming a ring road around its central business district (CBD).

Speaking to Engineering News on site in Limpopo on September 20, Sanral Northern Region project engineer Hennie Kotze explained that the main aim of the project was to divert the N1 traffic away from the CBD of Musina, with thousands of heavy vehicles using the N1 daily and passing through the CBD.

The project is, therefore, alleviating congestion, protecting the town’s road from heavy vehicles and leading to more efficient and less fuel-intensive travelling.

It is also contributing to improved mobility and the safe movement of goods, services and people in and around Musina.

Heavy vehicles add to the traffic congestion in town, while also creating conflict with local traffic and pedestrians.

The project entailed the construction of three major bridges, two interchanges (including on and off ramps), major earthworks (including large cuttings and fills), layer works and asphalt surfacing, 6 km of secondary roads, stormwater and subsoil drains, road furniture finishes (such as guard rails, road signs and fences) and noise barrier walls.

There is also scope for future expansion, should traffic volumes increase.

The project was also noted to have generated 281 jobs for locals, while 132 people were trained by accredited training service providers at a cost of R411 462.

Main contractor Raubex Construction also spent R28-million on procuring goods and services from local companies, while 20 local subcontractors were employed during the contract period, with Raubex spending R51.9-million.

The construction of the road was completed on August 8. Kotze acclaimed that feedback since the launch had been positive, with community members pleased with the outcome and aesthetic.

However, he said awareness of the road needed to be bolstered, so that drivers were cognisant of the alternate route, with many still going through the town.

“This will obviously not happen overnight, but once people adapt, we estimate that about 60% to 70% of the traffic will come through this route, away from the town,” Kotze enthused.

He said there was also a need for behavioural changes in drivers, to prevent incidents that have already been observed, such as improper use of the interchange and jaywalking – with the project including the requisite road signage, and walkways, to prevent this.

The project is “99% complete”, with the road fully functional. Only minimal supplementary work, such as rubble removal and some fencing, remains with this slated to be finalise in about a month, Kotze informed.

HANDS OF FRIENDSHIP

The project also aims to facilitate greater trade and economic activity between South Africa and its northern neighbour Zimbabwe, through the Beitbridge border post, as well other countries in the Southern African Development Community.

The route is dotted with varying versions of hand sculptures alongside the new road. Both ends of the route begin with the “narrative structures” of a few fingers rising from the ground, gradually developing in size and number along the road.

This ultimately culminates in the middle at the Nancefield interchange, where two pairs of hand hold up the bridge, and a full hand structure standing adjacent to the road.

KBK Engineers was appointed by Sanral to undertake the design and construction monitoring of the project. Also speaking to the publication was KBK Engineers project engineer Martin Boonstra, who explained that the architect wanted to convey the importance of the road being a link between South Africa and Zimbabwe, and its being the first bridge structure between the two countries.

The progression of the sculptures signifies a hand of friendship being extended between South Africa and Zimbabwe.

LONG ROAD

Kotze outlined that the project was first introduced by Sanral in 2004. Processes followed from this included interaction with the municipality to get its buy-in to the ring road; appointing engineering and environmental consultants; undertaking environmental steps; and undertaking the design, besides other activities.

Construction on the project began in 2016, following the appointment of Basil Reed as the contractor.

Owing to this lengthy timeline, as well as the complexities prevalent in such an ambitious undertaking, it was not without its challenges.

Boonstra outlined that the biggest challenge was when the initial main contractor, Basil Reed, went into business rescue. This resulted in the lengthy process, of almost a year, of sourcing another contractor, with Raubex Construction then appointed.

Raubex itself also ran into delays, owing to the pandemic, as well as a holdup with the relocation of one house along the route.

Other challenges pertained to relocation, in the ambit of environmental, social and infrastructure.

Kotze elaborated that there were several baobab trees that had to be replanted, as well the road needing to be designed around those that could not be moved. Moreover, to align to environmental standards, protected species in area that were removed to make way for the road also had to be transplanted where possible, or new ones planted to offset the loss.

With regard to social, there were several houses that needed to be removed to make way for the road, which entailed forming a cooperative and engaging with the community, and 30 new houses being constructed for the relocation of residents displaced by the project.

As alluded to, Kotze noted that there was a roadblock encountered with this, with one homeowner refusing to move, which caused delays and necessitated getting a court order for him to relocate, once other negotiation avenues had been exhausted.

In terms of infrastructure, the previous existing landfill site had to be relocated, given that the road traversed part of this.

Prior to the project, this site had been operating informally, and was not properly licensed with the environmental authorities. This necessitated undertaking a full, thorough process for the new landfill site, which entailed redesigning and creating a licensed, environment-friendly landfill with the correct materials; while the previous site was closed off and rehabilitated, Kotze outlined.

Therefore, a fortuitous benefit of the project was that a new, formal landfill site was created, with Raubex also providing the municipality with a guide and capacity for future expansion of the site.

Other infrastructure relocation entailed moving large powerlines that interfered with the route, with the team engaging with State-owned utility Eskom in advance to ensure that this was handled correctly.

Boonstra also outlined another challenge being the large cuttings going over an old copper mine, dating from the late 1800s. This required various investigations to ensure there would be no impact on the road, such as voids or tunnels forming.

The rocks here also had to be covered with a net and protective materials, to prevent them from eroding and falling.

“A project of this nature is much more complex and lengthy than one would think. It was an 18-year journey for us to develop this project, going through all of the environmental, land acquisition and authorisation processes, and undertaking discussions with service providers such as Eskom, and engagement with the community,” Boonstra emphasised.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation