Minor Revolution in Major Pyrometallurgy

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

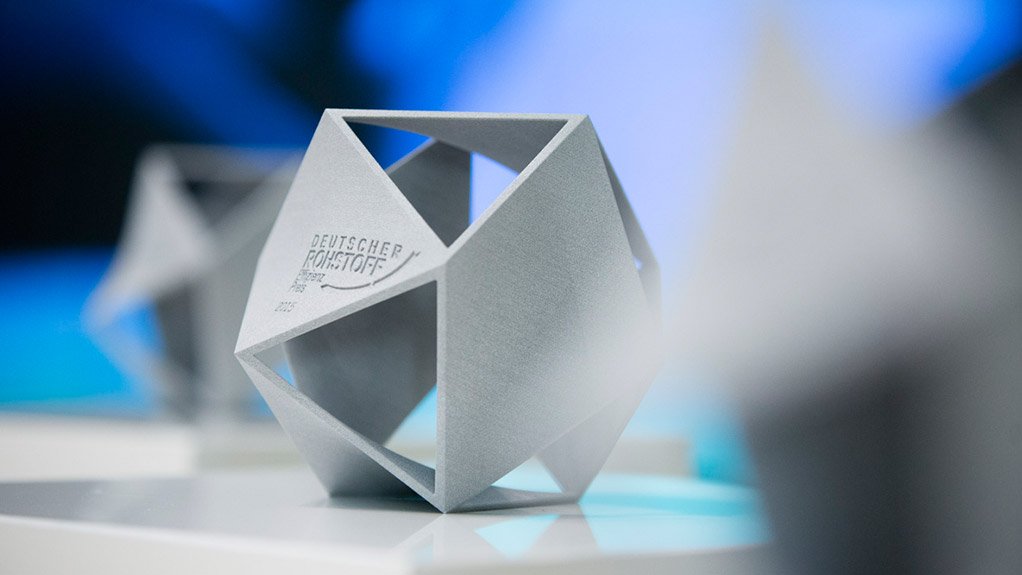

Company Announcement - The German raw material efficiency prize 2015 goes to IAS GmbH: The company located in Weil der Stadt develops innovative high performance cooling for sensors in high temperature applications

Outstanding scientific and economic projects have been awarded with the German raw material efficiency prize 2015. The award winning success stories exemplify the outstanding innovations for efficient and sustainable use of raw materials in both research and economics in Germany. The prize winners demonstrate in diverse ways how great leaps are possible in raw material efficiency. One of the prize winners is the company IAS GmbH from Weil der Stadt near Stuttgart. Managing Director Steven Hartmann received the award in Berlin. Mr. Uwe Beckmeyer, Parliamentary State Secretary at the Federal Ministry for Economic Affairs and Energy presented the awards. IAS is one of two award winners in the competition category for corporations.

Pyrometallurgy is an extensive sector in the extraction of raw materials up to the creation of semi-finished goods which operates with an enormous consumption of material and energy. Monitoring levels of molten glass and metals is a constant challenge for operators: How can the level be measured so that continuous ideal castability of the melted mass is ensured? Prevalent methods for controlling and monitoring such systems involve visual inspection by experienced employees, whereby the system needs to be opened or is permanently open. Generally, up to 20% of the energy in a casting system is wasted by opening the ovens.

The raison d'être for IAS GmbH is to develop and market a suitable cooling system to enable the use of off-the-shelf inductive or microwave sensors for measurements at temperatures of up to 800°C. The result is industrial standard prototypes of passively cooled sensors for durable applications in high temperature zones. These contribute to the improvement of automatic processes through a reliable non-contact detection of melting bath levels.

Ideal monitoring of molten mass in ovens, casting channels, and casting-dies

„The cooled sensor systems contribute to optimization of high temperature processes in metal and glass pyrometallurgy. They can be used for monitoring molten mass in ovens, casting channels, and casting-dies“, explains Steven Hartmann. A further field of application lies in controlling the position of hot semi-finished goods. As well as higher quality and increased production lot sizes, a significant increase in energy efficiency for these processes is also achieved. „Receiving an award for our innovative development makes us not only proud; it also demonstrates that the IAS high performance cooling for sensors in high temperature areas closes one of the still existing gaps in the foundry sector thus further optimizing production conditions.“

The German raw material efficiency prize is awarded by the Federal Ministry for Economic Affairs and Energy to Small and Medium-sized Enterprises as well as Research Centres for the development and implementation of raw material efficient products, processes, and services. The jury includes representatives from science, economics, and business.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation