Furnace and smelting plant specialist highlights innovations

STOPPING SLAG FLOW Tenova Pyromet’s slag valve was installed and commissioned on a 12 MW furnace

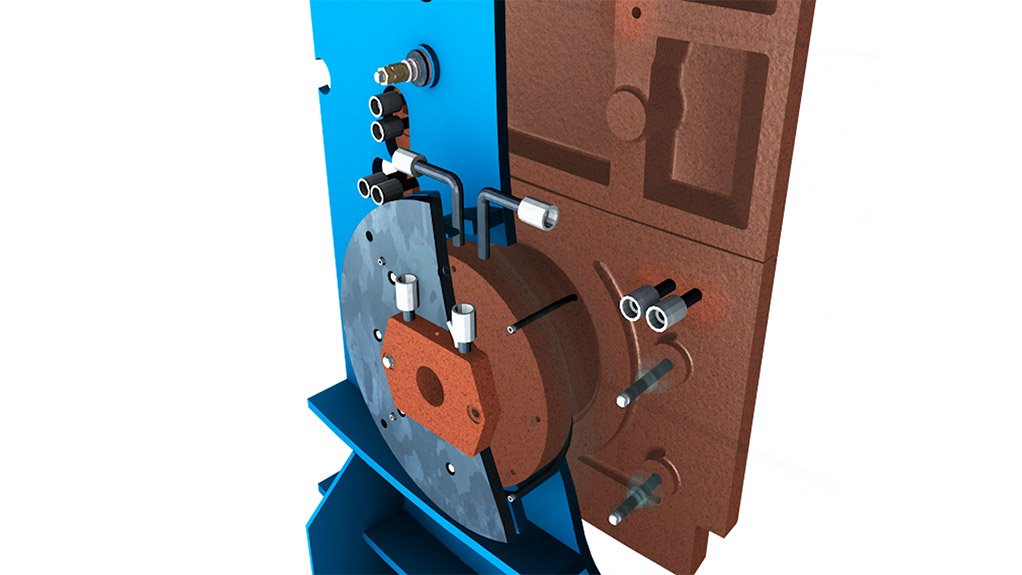

WATER-COOLED COPPER TAPHOLE BLOCK Water-cooled taphole blocks extend the life of taphole refractories

CHRIS OERTEL Tenova Pyromet developed a new plate cooler design that is in use on a six-in-line furnace at Northam Platinum’s Zondereinde mine

High-capacity furnace and smelting plant specialist Tenova Pyromet presented two developments to improve slag tapping at the South African Institute of Mining and Metallurgy Furnace Tapping conference in May.

At the conference, which took place at the Misty Hills Country hotel, in Muldersdrift, Gauteng, Tenova Pyromet highlighted how an improved slag-flow control valve performed consistently well on its first commercial installation, operating under more challenging conditions than specified in the original design criteria.

Tenova Pyromet MD Chris Oertel tells Engineering News that the company’s slag-flow control valve is designed to throttle the flow of slag.

Additionally, the Tenova Pyromet slag valve offers remote closing under normal and emergency conditions, and can be used in conjunction with standard tapping equipment, such as drills, clay guns and lances.

“In mineral wool furnaces, for example, control of the tapping rate of molten slag is a requirement of downstream spinning equipment to maintain consistent fibre quality.”

Further, Oertel says the Tenova Pyromet slag valve was installed and commissioned on a 12 MW furnace as part of a new mineral wool plant, in the US.

“Although the design intent was for controlling slag flow rate with occasional use as a shut-off valve during emergency shutdown conditions only, the valve became the preferred method to the mud-gun system of closing the furnace during the first six months of operation.”

Oertel notes that only a few minor changes to the installation were required to enable the valve to cope with the increased heat load, and significantly higher frequency of use.

“Continuous operation of the taphole requires robust equipment design, as it subjects all equipment in the taphole area of the furnace, including the slag valve, to high heat loads,” he explains, adding that it does not allow for frequent maintenance.

Owing to space constraints of the taphole area, Oertel says a compact design was required that was also easy to maintain.

He further highlights that the company’s slag valve is also simple to maintain, with a steel flange installed to facilitate taphole repair and replacement from outside of the furnace.

Meanwhile, Oertel states this technique is a reliable and robust method for closing a furnace.

“Applications of the slag valve assembly are broad and it can be retrofitted to most existing slag tapholes with minimal modifications. It can also be easily installed as an emergency backup to most slag tapholes, as well as to add a level of control upstream of slag granulation processes which improves its consistency and safety,” he adds.

Water-Cooled Copper Blocks

Oertel says another slag-tapping improvement solution – water-cooled copper blocks – is “successfully operating on metal, matte and slag tapholes for several processes, including nickel, platinum-group metals (PGMs) and mineral wool”.

“Water-cooled taphole blocks have proved to be an effective solution for those applications where the metal and/or slag are damaging to the refractory, or where operations are at several hundred degrees of superheat.”

He highlights that these blocks provide an effective means of extending the life of taphole refractories, as the resulting lower temperature of the refractory material not only inhibits wear and other damage, but also, promotes formation of a protective frozen slag layer.

“This is particularly beneficial during prolonged tapping cycles,” he emphasises.

Further, Oertel points out that, as the copper block forms an integral part of the lining, it provides mechanical support for the refractory, facilitating rapid replacement of tapping channel bricks without disturbing the surrounding lining.

“Safety considerations are an important design factor. Positioning of the water channels has been improved to prevent leaks, although the copper is not in direct contact with the molten fluids during normal operation,” he adds.

Novel Lining and Sidewall Design

Oertel notes that the company has developed a new plate cooler design, which was installed on a six-in-line furnace at PGM miner Northam Platinum’s Zondereinde mine, in Limpopo, in January.

The project followed a prefeasibility study, which was awarded in 2010 to Tenova Pyromet by Northam Platinum, to uprate the capacity of the mine’s six-in-line furnace from 15 MW to 25 MW.

“Additionally, Tenova Pyromet recommended that plate coolers be fitted on the furnace sidewall to operate safely at 25 MW,” he explains.

“Thermal calculations indicated that the refractory life at 15 MW operation would be extended by cooling the side-wall. Adoption of plate coolers prompted installation of an additional water supply system, which included cooling towers, a pumpstation, piping, electrical and instrumentation,” Oertel concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation