AfroxPac 35i self-rescuers more dependable than ever

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

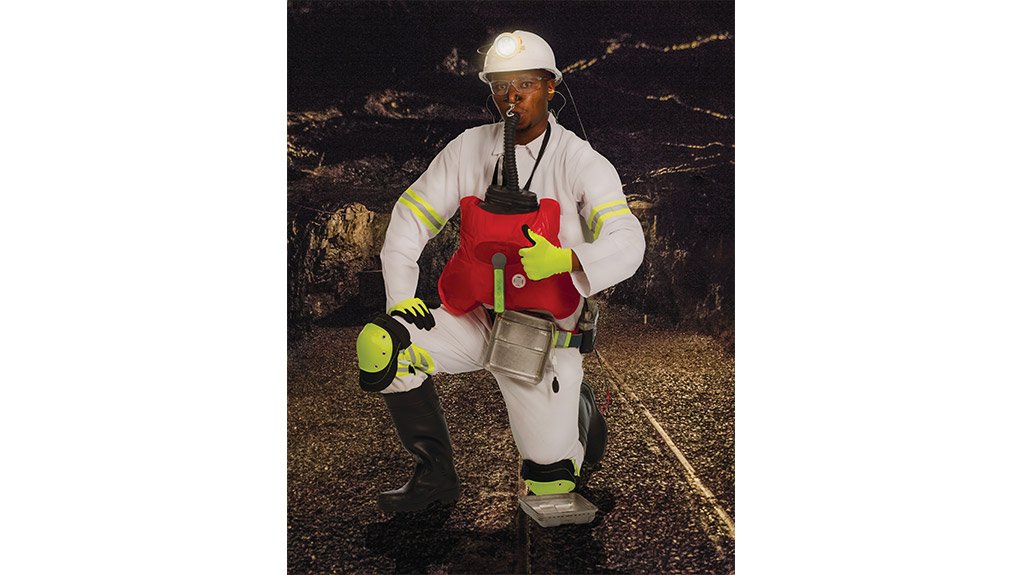

Safeguarding miners against toxic smoke and oxygen-deficient atmosphere is vital for protecting underground workers. Manufactured by Afrox, the AfroxPac 35i is a closed-circuit, chemical oxygen generating, body-worn emergency breathing device primarily used for escaping toxic atmosphere in mines. The self-contained self-rescuers are collectively carried by underground miners in Africa for more than 1.5 million hours each day, delivering life-saving oxygen in an emergency.

Peter Rowlands, Business Manager Afrox Self-Rescue Division, says that the division is ISO9001 and ISO14001 compliant, and maintains an ethos of “A life depends on it” which dominates every aspect of manufacture from production right through to post-production support. Accordingly, the division’s move to new facilities on the Afrox Germiston Campus in 2017 was expected to deliver results, especially from the all-new ‘dry-room’ chamber where the breathing apparatus – the heart of the AfroxPac 35i - is assembled under strict, climatically controlled, moisture-free conditions.

Two years on, batch testing results on new AfroxPacs, performed independently by the Accredited Testing Authority (CSIR), have realised the benefits of the Afrox investment, providing simulated breathing durations that are consistently above 35 minutes. This provides a significant margin of safety compared to the rated duration of 30 minutes.

“Considering the exposure to harsh conditions of use over many years in our customers’ mining environments, this provides the assurance that their escape strategies can be planned according to the rated breathing duration of the AfroxPac 35i,” says Rowlands.

The climate-controlled dry room, essential for handling moisture-sensitive chemicals, has advanced instrument control and improved ergonomics, allowing for improved material flow and regulation and better production and consistency in the quality of the self-rescuer.

“The AfroxPac 35i is ideal for tough African mining conditions in that it complies with the demanding SANS1737:2008 standard for self-rescuers, having the added dimension of accelerated durability testing which does not feature in other international standards. This makes the compliance testing process one of the toughest in the world for self-contained self-rescuer (SCSR) standards,” says Rowlands.

Rowlands notes that a focused research and development team is dedicated to constantly improving the long-term performance of the units and that Afrox prides itself in operating one of the few privately owned breathing simulators in the world.

Afrox has successfully designed, manufactured and marketed AfroxPac SCSRs since 1996 and many underground mining workers escape hazardous mining conditions safely each year using the units. Afrox’s self-rescuer was developed in close association with the African mining industry and is 100% locally manufactured and supported, having been tested under some of the toughest mining conditions in the world.

The AfroxPac 35i was first launched in 2012 and replaced the original AfroxPac 35, with significant advances including improved long-term breathing performance and heat resistance, increased protection of high-wearing points on the external protective casing, and the inclusion of an internal seal adding an extra barrier to moisture ingress while providing for improved chemical containment.

Currently AfroxPacs comprise more than 60% of the South African self-rescuer market and are represented in significant quantities across virtually all the hard-rock and many coal underground mining operations.

Afrox is sub-Saharan Africa’s market leader in gas and welding products and constantly strives to meet the needs of its customers and develops solutions that add value to customers’ applications.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation