thyssenkrupp drives digitalisation

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Digitalisation, propelled by the 4th Industrial Revolution, holds the key to unlocking enormous opportunities and growth for classical engineering companies like thyssenkrupp. Recognising the role of digital technology for sustainability, thyssenkrupp is constantly looking at new and innovative ways to embrace the digital age. #hack4tk, hosted annually by thyssenkrupp AG in Essen, Germany, is a game-changing initiative that maximises digital potential by fostering creative thinking and innovation and inspiring participants to solve complex challenges utilising digital technology.

When Andrew Gotora, an Engineering Programmer at thyssenkrupp Industrial Solutions South Africa (tkISSA) who has a passion for all things digital, heard about the hackathon, he saw an opportunity to not only demonstrate how digital technology can be used to solve a challenge but also utilise digital technology to partake in the hackathon remotely. Gotora assembled a five-member South African debutant team that walked away with an innovations award.

The gruelling 24-hour competition which took place on 3 and 4 July 2019, welcomed individuals from all corners of the world, both from within and outside of thyssenkrupp, who believe that they have what it takes to find a solution to these challenges.

The participants bring their bright minds and fresh ideas, untainted by pre-conceived notions on how things should be done. These outside-the-box thinkers have the capabilities to develop innovative and ground-breaking solutions that have the potential to provide thyssenkrupp with a breakthrough for that competitive edge.

Gotora’s team consisted of one German and five locally based coding enthusiasts with expertise in the fields of engineering, artificial intelligence (AI), computer vision and data science. Out of the ten hackathon challenges, the team selected both the ‘Bot’ and ‘Autonomous plant start-up’ challenges and they split their team into two groups, with three team members working on each challenge.

The ‘autonomous plant start-up’ challenge which was derived from a water electrolysis plant in Germany captivated Gotora and his team. He explains that they immediately recognised that automation was the link between the challenge and a similar tkISSA digital project, Liquid Fuel Storage (LFS). “The autonomous plant start-up challenge closely resembles LFS, an automated engineering solution that is part of tkISSA’s digital migration.”

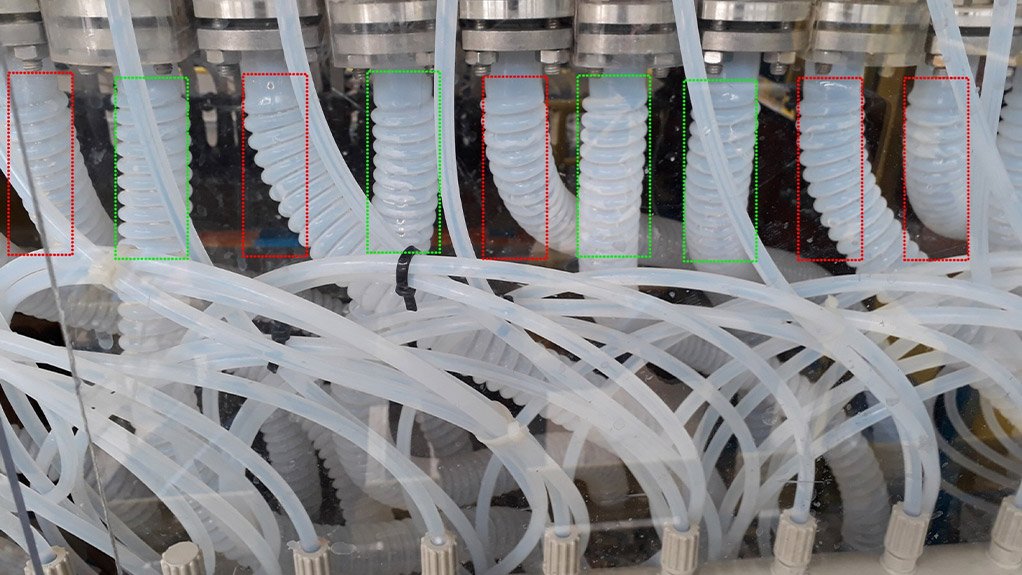

The water electrolysis technology delivers ’green’ hydrogen, a clean, CO2-free energy carrier, by splitting water into hydrogen and oxygen. The only inputs needed are water and renewable electricity from wind, hydro power or photovoltaics. Prior to plant start-up, technicians are currently sent out to manually check if there is water flowing out of electrolysis cells. Gotora points out that if there is no water in the cells during plant start-up, the electrolysis cells will get damaged. The challenge was to automate the checking process as well as the plant start-up.

With two members working from the thyssenkrupp Johannesburg office and the third, based at thyssenkrupp AG in Germany, the forward-thinking trio successfully used the internet and a variety of digital platforms including social media to solve the challenge. Using a computer, a camera and software, Gotora and his team automated the detection of fluid flow. Once the system has detected and confirmed fluid flow out of all the cells, the plant automatically starts up. However, in the event of no fluid or flow, the system alerts the technician.

Expressing his gratitude to his team for their hard work and determination over those intense 24-hours, Gotora says that it was leveraging on digital technology that made the winning solution possible. “Providing a solution remotely and in real time to an engineering challenge that is 8 440 km away, using digital technology is a perfect demonstration of digitised engineering,” notes Gotora.

He emphasises that companies that provide innovative, effective and efficient customer-centric solutions will see a continued growth and sustainability in this digitised age. tkISSA is moving on to a digital engineering model that combines its classical engineering expertise with digital technology to develop new services and solutions that meet - changing business and market requirements.

“Sihalalisela (congratulations) South African hackathon team!” says thyssenkrupp Industrial Solutions South Africa CEO, Sub-Saharan Africa, Philipp Nellessen, who affirms the company’s ongoing dedication to embracing digital technology to the benefit of not only South Africa but also the rest of Africa.

“With deep roots in Africa that span 60 years, thyssenkrupp is passionate about developing the immense potential that this continent holds in the digitalisation space as well as empowering the people and the communities across this vast and untapped territory.”

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation