Technologies advance production processes

Fully integrated and customised technologies are being used to automate, integrate, upgrade and streamline production processes.

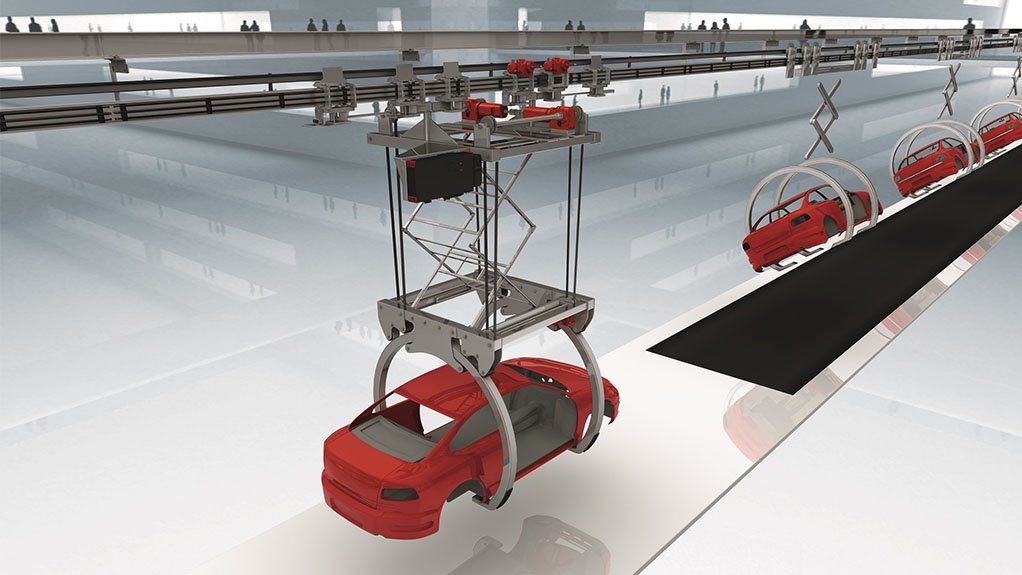

SEW-EURODRIVE believes that exchangeable modules are the future of factories and its MAXOLUTION® systems are designed to enable manufacturing operations to become ‘smart factories’ with a flexible and adaptable modular structure where components and machines are added, duplicated or removed. This provides for greater flexibility, enabling production processes to be efficiently adjusted as required.

”Whether a customer is needing to source or enhance automated guided vehicles, electrified mono systems (EMS), or replace or upgrade motors and gear boxes we can guide them from the project planning stage through to installation ensuring that our customised software meets requirements, that communications between machines is configured correctly and that their entire production processes is seamlessly automated, integrated and optimally calibrated for best performance with one eye on Industry 4.0 and the other eye on the future,” says SEW-EURODRIVE MAXOLUTION® engineer Dylan Enslin.

“At SEW-EURODRIVE the technologies behind our MAXOLUTION® systems are extremely advanced and take into consideration that industry and its processes are constantly evolving, recognising the requirement for future upgrades and adjustments.”

The company recently developed a machine automation project with its customised software solution and also implemented the concept for torque testing machinery in the mining sector. In addition, the solution has been used in the automotive manufacturing sector for an engine line where travel axis/hoist axis, gearbox sizing, variable speed drive requirements, motor positioning and electronic communications were specified for the implementation of an EMS system.

"We assist the customer in selecting the best solution for their production requirements by ensuring that all components meet the customer’s requirement and are compatible in order to deliver a successful integration that supplies smart technology, machinery communications coupled with a smooth, seamless and efficient system. MAXOLUTION® offers maximum flexibility with maximum availability – in short we automate and integrate your systems reliably and efficiently,” asserts Enslin.

SEW-EURODRIVE liaises with external system integrators or original-equipment manufacturers to assist with project planning, costings, customised or standard software solutions, design recommendations and commissioning. It has access to the international company’s wide range of technologies and applications, as well as a large and comprehensive stock holding of components that can be dispatched at short notice.

“Nothing is out of reach when it comes to problem solving and conceptualising a future-based integrated system solution from planning through to design through to commissioning,“ says Enslin.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation