Structural bearings support stadium beam joints

Since Vesconite Superlube was to be used as a sliding bearing, the bearing material was contained within two stainless-steel plates, which would slide relative to each other to allow for translational movements in a horizontal direction

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

A time-lapse video proves that Vesconite Superlube low-friction, high-load-carrying bearings perform well as sliding bearings in large structures, including soccer stadiums.

The video starts shortly after 7pm and shows structural movement throughout the evening, when the stadium concrete beams contract due to cooling, and continues past mid-day, when higher temperatures result in expansion.

These subtle movements, when allowed by a bearing, ensure the safety and the structural stability of the stadium and the continued support of the superstructure by the support columns’ substructure.

Since the stadium was designed to have a capacity of 55,000 spectators, expandable to 75,000, engineering performance was paramount to ensure the stadium withstands temperature- and moisture-related contractions and expansions, as well as earthquake and wind loads.

History of the stadium

The stadium was built more than ten years ago, and has been used for large sporting events.

The original bearings were a bitumen-impregated cloth. The columns and beams were made from traditional concrete.

However, after eight years of use, excessive wear was found to the concrete of the continuous support beams and to the supporting columns.

The bitumen-impregnated cloth had been torn or ripped away in some cases, and pieces of concrete in the beams and columns had disintegrated at the corners.

Engineers motivated that an unfortunate congruency of design and building errors, combined with a choice of original bearing materials not suited to the design, necessitated an urgent review of bearing materials and expansion gap designs.

Problem 1 - Small expansion gap

All materials shrink and expand as temperature varies, so an expansion gap is required. Concrete has a known expansion rate so it is important that designs cater for this expansion.

In this stadium in which Vesconite Superlube was eventually installed, the original bearings, made from bitumen-impregnated cloth, were employed at the expansion gap to prevent the columns from bonding with the continuous beam placed on top of them.

The original contractors poured the column first and then used the bitumen-impregnated cloth to separate the column from the continuous beams.

For a joint that doesn’t move much this would have been suitable. But, in the case of the stadium, the gap size and the material specified proved inadequate and concrete was ripped out adjacent to the provided-for gaps.

Problem 2 - Inadequate steel reinforcement and concrete cover

Since concrete is good in compression but not in tension, many structures, including bridges, have steel reinforcement to resist tensile forces. The steel tends to follow the contour of beams and columns with a certain amount of concrete cover. This prevents corrosion of the steel and the spalling of the concrete that results from exposure to the environment. However, at the stadium, concrete beam and column corners were inadequately strengthened with steel, and the corners cracked off leaving an inadequate bearing surface.

Some steel was badly positioned, possibly because of a lack of oversight during construction. The poured concrete moved, and the steel was not close enough to the surface to keep the corners strong.

The Vesconite Superlube solution

The existing bitumen-impregnated cloth was replaced with Vesconite Superlube, which is a low-friction, high-load-carrying bearing material.

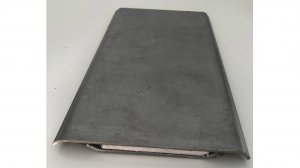

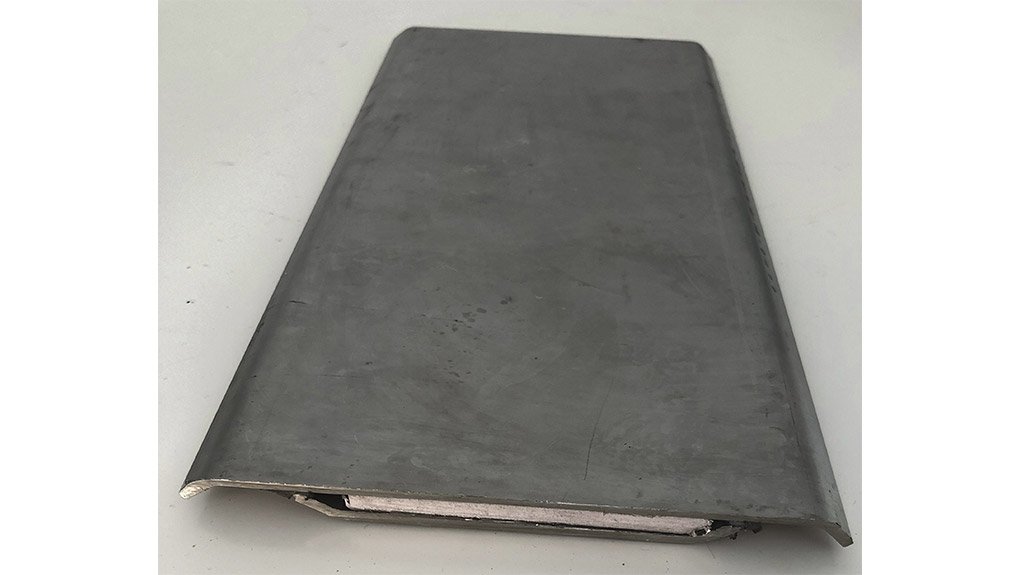

Since Vesconite Superlube was to be used as a sliding bearing, the bearing material was contained within two stainless-steel plates, which would slide relative to each other to allow for translational movements in a horizontal direction.

Unlike various other stainless steel sliding bearing designs, the engineering contractor chose a top metal plate that arched down to join the bottom plate so as to reduce the ingress of dirt. The bottom plate was also longer than those traditionally used in sliding bearings and had a lip at each side; the length maintained the horizontal rigidity of the bearing during installation.

Since there were significant engineering design and maintenance problems in place at the site, installing the Vesconite Superlube bearing solution involved several measures to address existing structural issues:

- Hydraulic jacks were brought in to lift beams off the supporting columns.

- Where concrete columns or beams had had extensive pieces of concrete ripped off them, these were repaired by putting in form work and pouring concrete to ensure that the corners were intact.

- Saws with large cutting wheels were used to cut out the ledges on which the Vesconite Superlube bearings were to be placed.

- Epoxy bedding compound was placed on to the stainless steel top and bottom coverings of the Vesconite Superlube bearing to create a level bearing surface.

Vesconite Superlube in structural design

In structural design, vertical load is considered as well as horizontal load. These two loads are used to determine the required column base-strength and the amount of steel and concrete.

If there is a bearing on top of the column, the horizontal force that needs to be taken into account depends on the amount of friction at the top of the column. If you have a lower-friction bearing, then an engineer can design for a lower lateral force, which means less steel and concrete is needed for the column.

“You want those lateral forces to be minimised,” notes Thomas Utermark, the Vesconite structural engineer who was involved in the project.

“That is why Vesconite Superlube could be used very effectively here. The benefit is very low friction with wear resistance that is much better than PTFE,” he says.

Another benefit of implementing Vesconite Superlube in this application was that a smaller bearing could be used, taking advantage of Vesconite Superlube's high load-carrying capacity. “If there is a space constraint, that is helpful to an engineer,” Utermark notes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation