Small. Smart. Unique. The Pepperl+Fuchs M-LB-5000 Surge Protection System

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Process engineering plants must be protected against surge voltages to avoid jeopardising their availability. However, the surge protection modules must be checked regularly and replaced if necessary. This requires significant effort if the checks are carried out manually, and restricts operation if a signal circuit has to be switched off for the module to be replaced. Using the modular M-LB-5000 high-end system with diagnostics eliminates extensive testing and operational interruptions. It is supplemented by the M-LB-2000 system for applications in which a minimum specification with additional loop disconnect is sufficient.

Surge voltages have many possible causes. Electronics can receive sustained damage from lightning strikes, transients caused by switching operations and load drops, and interruptions to the supply. There are other effects in addition to the direct destruction of components, in particular the risk posed to plant availability and the resulting consequences, such as production downtime, which drives operating costs up. Surge protection systems must therefore form an integral part of process engineering plants. In addition, current standards such as EN 62305 (SANS 62305) require that the effectiveness of these systems be checked regularly. Up to now, this check has usually been carried out manually on-site, which is very costly for large plants in particular, and requires trained personnel and tools such as a test kit. However, the test results do not give any indications of prior damage to the protection module and its state of wear. It has previously only been possible to rate the tested devices as "good" or "bad." To meet the different safety requirements of the signal line market, Pepperl+Fuchs offers two surge protection systems with different functions.

Surge Protection with Condition Monitoring

The M-LB-5000 surge protection system with condition monitoring function monitors signal lines automatically and continuously. The patented diagnostics use a special algorithm to detect the different load situations that cause the surge protection system to wear. This includes counting the number of times the gas discharge tube has ignited, detecting the silicon temperature of the suppressor diodes, and measuring the interior temperature of the surge voltage protection module. When the protection module has reached 90 % of its life cycle, this is indicated by a yellow diode. The protection modules are therefore replaced neither too early nor too late. Replacing them too early leads to an unnecessarily high replacement frequency, while replacing them too late leads to the plant having phases without sufficient surge protection if defective protection modules are not replaced immediately. This optimises the availability of the surge protection functionality and of the plant, and at the same time minimises maintenance costs.

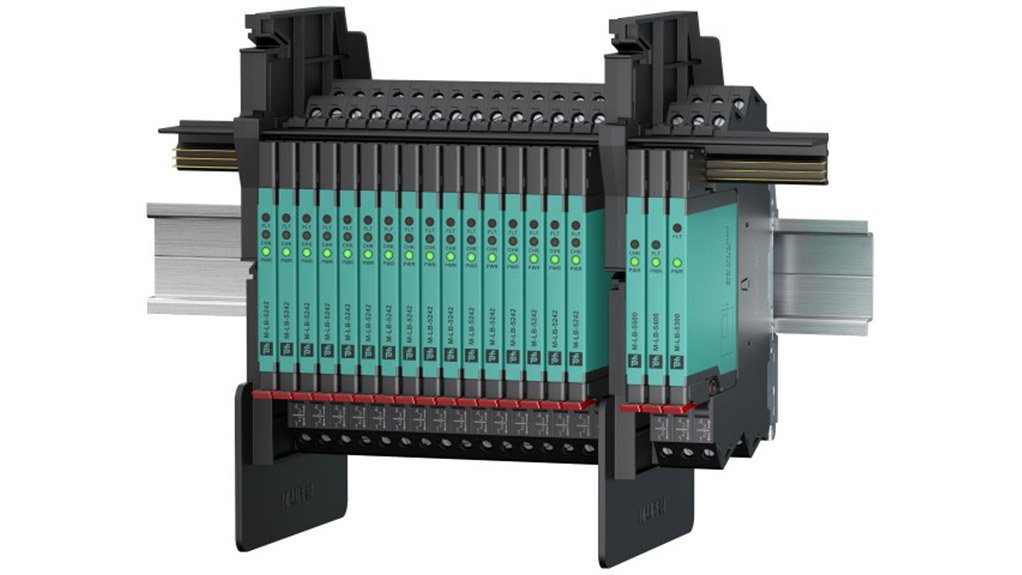

The M-LB-5000 modules are mounted on a standard DIN mounting rail. The devices each consist of a base module and the actual protection module. The system also has an insulating partition to maintain clearance when mounting Ex and non-Ex modules on a DIN mounting rail. All modules have a width of only 6.2 mm and allow simple commissioning without special aids. In addition to the protection and base modules, there are three function modules. The maintenance module reports when a yellow LED lights up on at least one protection module, indicating that this module should be replaced. The fault module indicates when at least one device has a fault (red LED) and needs to be replaced directly. The third unit is a power module that powers the protection modules via the power rail. The error messages are also sent to the function modules or the control panel via the power rail.

Protection Modules with Signal LEDs

The intuitive, easy-to-read traffic-light display on the protection modules greatly reduces testing effort since the fault can very easily be assigned to a specific signal circuit. A green LED on the protection module means that the full protective effect is present, there is a sufficient functional reserve, and there is no need for action. As part of the condition monitoring function, the yellow LED signals that the protection module has reached 90 % of its life cycle. The signal circuit is still protected, but the module should be replaced soon, for example during the next regular servicing. A red LED indicates that the protection module may be permanently damaged and no protective effect can be guaranteed. It should be replaced immediately to prevent damage during the next surge voltage event.

The Benefits of Modularity

During maintenance, the modular assembly of the surge protection system offers significant advantages compared with conventional solutions. Due to the base module on the DIN mounting rail, removing the protection module does not cause a signal interruption. The signal circuit is closed without interruption via the base module at the moment when the connection between the signal circuit and the protection module is no longer established. A protection module can therefore be replaced without affecting plant operation. An additional loop check is not necessary.

However, if the signal circuit needs to be intentionally interrupted—for isolation tests during commissioning or in recurring tests—the protection module can simply be rotated by 180 degrees and plugged in. In this case, the signal circuit is interrupted by an integrated isolating function. This allows the module to replace terminal blocks in the cross connect level with no additional space required. This combination of condition monitoring, more than 100 modules per function module block, loop separation, and 6.2 mm width with single-loop integrity is unique on the market.

Terminal Block with Surge Protection

Pepperl+Fuchs has developed the M-LB-2000 for applications requiring only minimum specifications plus loop connect. It has a form factor very similar to the M-LB-5000 and is designed to be attached directly to the DIN mounting rail. The main differences are that the module cannot be diagnosed or replaced without interrupting the signal line. A loop disconnect function is achieved when the module is plugged in via two easily accessible switches on the front.

The M-LB-2000, which is also only 6.2 mm wide, not only saves a lot of space in the switch cabinet, it practically replaces the terminal block with surge protection. This means that disconnect terminal blocks are no longer necessary, saving costs. The certificates range from ATEX, IECEx, Zone 1 and SIL 3.

Conclusion

The M-LB-5000 surge protection system's diagnostics use a special algorithm to detect different load situations and send a signal when the protection module has reached 90 % of its life cycle. This significantly increases the efficiency of the protective function and keeps maintenance costs to a minimum. The modularity of the device enables the protection module and loop disconnect to be replaced without tools and without interrupting operation.

The M-LB-2000 with loop disconnect function is designed for significantly lower requirements in surge protection. With a width of 6.2 mm, it saves just as much space in the switch cabinet and can be used as a replacement for the terminal block with surge protection.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation