Seamless plant switchovers on Zest WEG genset solutions

The 550 kVA gensets being assembled at the Zest WEG manufacturing facility in Cape Town.

Six gensets being assembled for a client in the marine sector at the Zest WEG facility in Cape Town.

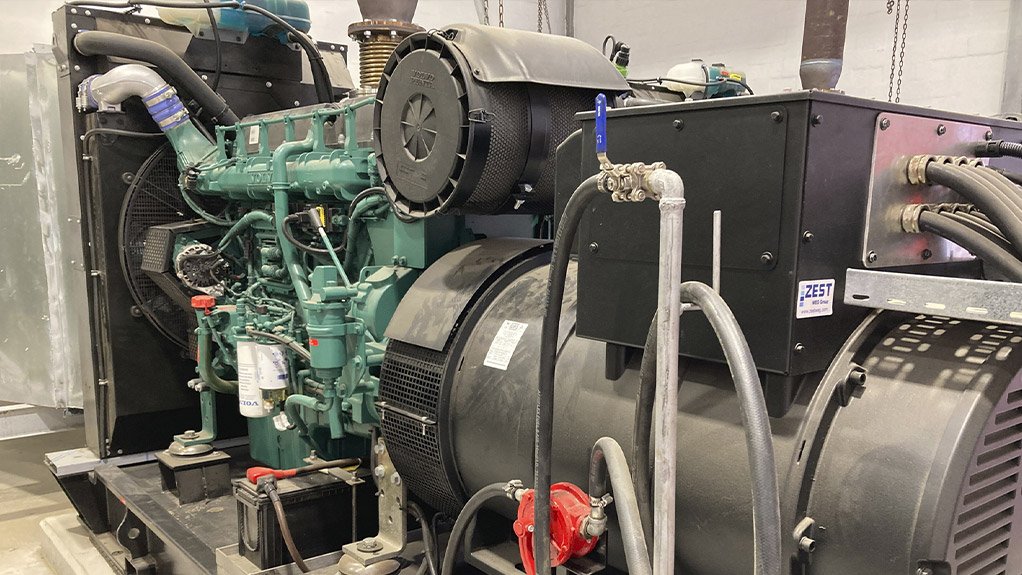

The 550 kVA gensets in the generator plant room on-site.

A view of the client's generator plant room.

Zest WEG is known for its standby power solutions ensuring reliable power during power disruptions.

A Zest WEG genset powered by a Volvo engine.

As power outages and loadshedding continue to plague the optimal performance of industrial and mining process plants, Zest WEG is providing standby power solutions that ensure no power loss when these disruptions strike.

According to Damian Schutte, electrical engineering team leader at Zest WEG, many plants face complex and lengthy restart routines if there is a power failure on the main grid and this severely compromises plant efficiencies.

“With our design and manufacturing experience, we can provide genset solutions that can be started up prior to an outage, so that the plant can continue operating seamlessly while switching from utility to standby power, and back again to the utility,” says Schutte.

Adding to this, he highlights that Zest WEG’s customer-focused approach means that it responds positively to the challenges that companies face in scheduling and implementing these backup systems. In a recent project in the Western Cape, the Zest WEG team provided a plant to a customer in the marine sector with a customised genset solution to suit its specific needs and also help the customer face unexpected circumstances.

The plant was experiencing considerable downtime due to loadshedding by the national utility, as it would take some time to bring the plant back to operation. The engineered solution includes six 550 kVA generators, two 11 kV transformers, medium-voltage (MV) switchgear, and breakers for synchronising between generators themselves and also with the utility.

“The smaller size of generator provides flexibility and was a cost saving, as some units can be switched off depending on the site load requirement,” he says.

When frequent loadshedding was suddenly announced by the utility, the customer asked Zest WEG for an urgent temporary solution while continuing to implement the project. The team brought three of the gensets on-stream to keep the plant functional until the planned solution was in place.

Bradley van der Spreng, business development consultant at Zest WEG, notes that all major components for power plant solutions such as these can be manufactured and assembled by Zest WEG and Brazil based parent company, WEG. The company can, however, accommodate a client’s specifications should they refer to a nominated supplier, allowing the gensets to be built for easier on-site installation.

“Our extensive engineering and programming on these systems makes it vital that they are fully tested before being delivered to site,” says van der Spreng. “Whatever we specify in the contract can usually be tested in-house at our advanced facility in Cape Town.”

Customers are invited to attend the factory acceptance test (FAT), which includes load testing of the generators at different loads up to 110%, synchronisation checks, and MV tests if this is part of the scope.

On behalf of Zest WEG

Facebook: https://web.facebook.com/ZestWEGGroup/

LinkedIn: https://www.linkedin.com/company/zest-electric-motors/

Twitter: https://twitter.com/ZestWEGGroup

Instagram: https://www.instagram.com/zestweg/

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation