Project to restore Durban Dry Dock under way

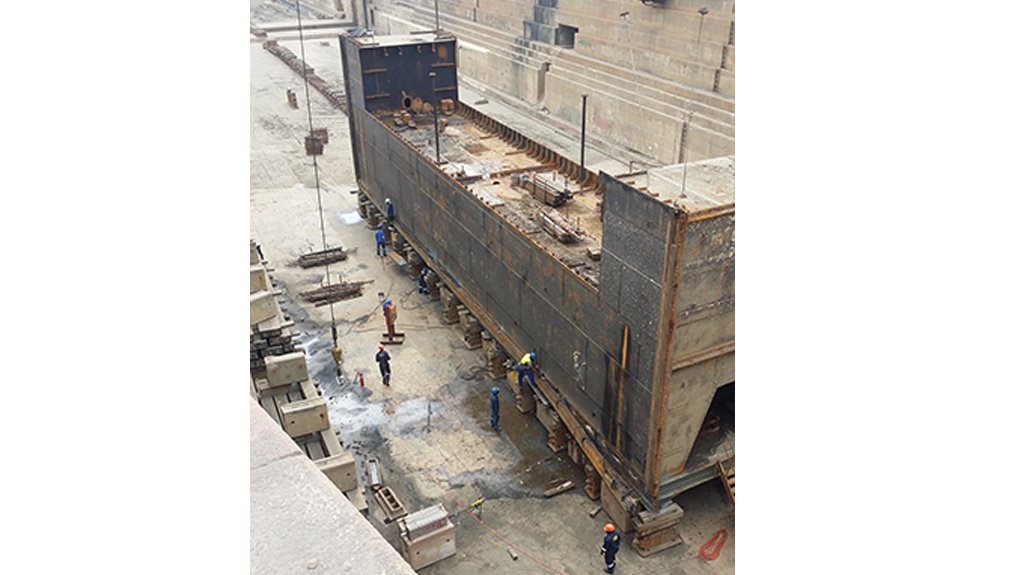

The rehabilitation of the inner caisson, which divides the Port of Durban’s Prince Edward Graving Dock into two compartments, enabling two smaller vessels to be docked simultaneously, is in full swing.

It is among 11 large-scale projects earmarked for the Durban Dry Dock complex.

“The R61.5-million project to repair the inner caisson and upgrade the drive system has been undertaken to ensure the safety of the dry dock and the sustainability of the ship repair business in Durban,” says Port of Durban deputy port engineer Dumisani Mkhize, who is managing the project.

“Rehabilitation of the inner caisson will improve the operational efficiency, reinstate the dry dock to its full capacity and improve operational safety,” comments Port of Durban ship repair and workshops business unit manager Erwin Skeepers.

“It will equip ship repairers who use our facility to be more competitive, helping to attract more business to South Africa.”

The rehabilitation follows extensive technical studies which identified parts of the caisson that had aged and deteriorated and were in need of attention. Various options were explored with professional inputs and, ultimately, it was decided to repair the inner caisson to the original design.

The rehabilitation includes major structural design improvements on rebuilt decks and compartments, which are being built in a controlled environment in an off-site engineering workshop. These will be pre-trial fitted before being sent to site, greatly improving fabrication quality and ease of fitment on site.

Design and fabrication of the new steel sections has already been completed.

“The caisson has been taken apart at C and D deck levels and the A and B deck steel structures have been cut up for scrap. The next big milestone will be bringing new sections of C and D decks for installation on top of the rehabilitated DE section,” says Mkhize.

The project, which is being carried out by two Durban-based companies, Lodemann, as the managing contractor, and Channel Construction, the designer – both of which were appointed in May 2018 – is expected to be completed by November.

The work schedule is being managed in consultation with the ship repair industry to promote a “win-win” situation where ship repair work in the dock can be reasonably sustained during the project.

The rehabilitation project falls within the Transnet National Port Authority’s contribution to Operation Phakisa – the government initiative to unlock the oceans economy by investing in infrastructure, skills and capacity building, to grow the market and, in so doing, create much needed jobs.

Job creation in the marine sector has a strong multiplier effect, with an estimated five indirect jobs created for every direct job. This particular contract has created direct jobs for 29 skilled employees, including seven youth, and nine jobs for semi-skilled persons, including three youth.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation