Need for new tech knowledge across industry

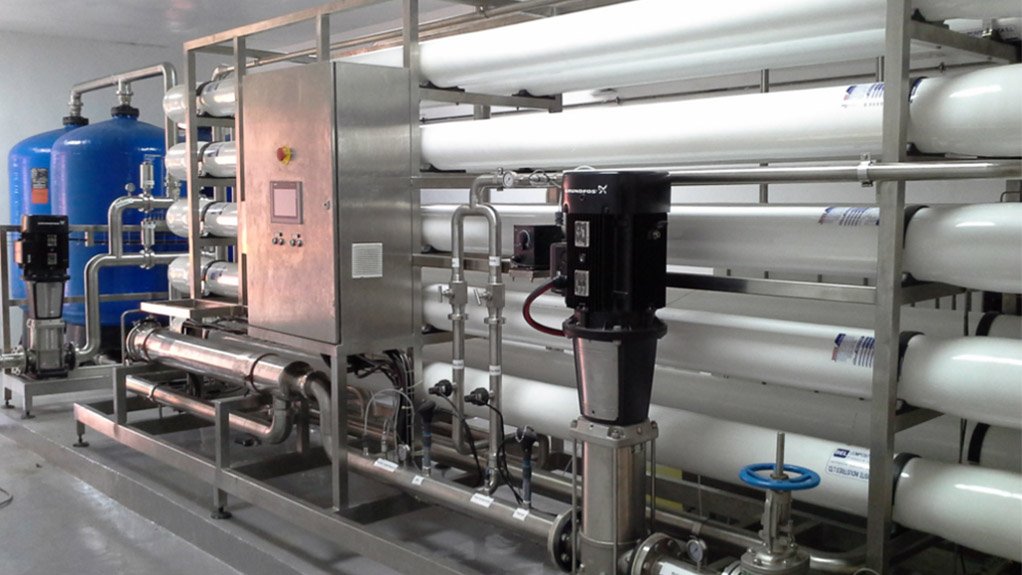

PURIFIED SOLUTIONS The company provides solutions to various water treatment challenges to add value to the process

TREATMENT SOLUTIONS 3M works with Sagisa to provide applications to customers

With technology advancing in the wastewater treatment industry, industry needs to be educated on the latest available solutions that will improve operational economies and ensure long-term cost-savings, says separations and purification company Sagisa projects manager Lourens du Plessis.

Sagisa continuously has roadshows and onsite training in all sectors of our business to introduce and promote new technologies in the market. This is also done to ensure the current installed systems are operated and maintained according to recommendations.

According to du Plessis, Sagisa provides solutions to various water treatment challenges by designing, building, installing and commissioning systems to ensure a turnkey solution, which adds value to the process.

Associated with global market leaders in the sector – such as chemical company, Dow DuPont, multinational conglomerate corporation operating in the fields of industry, health care, and consumer goods. 3M and developer and manufacturer of spiral, tubular and hollow fiber membranes, Koch Membrane Systems who are globally trusted and recognized – the company’s track record and continuous support for similar applications globally has instilled confidence in the local market.

“As a result of this, the solutions are well received, and customers are more willing to consider using them,” Du Plessis adds.

With the company already having ongoing projects in the automotive, petrochemicals, medical, food and beverage and mining sectors, its new projects include mine water recovery, dialysis systems, oily wastewater recovery and juice processing.

“Sagisa also supplies water treatment technologies to popular fast food restaurants,” he says.

The company has products that cater specifically for applications that will remove particle and bacterial contaminants from water.

Du Plessis says that water can be taken from sources such as municipal water, ground water, well water and sea water. These also include wastewater recovery that can be implemented to recover and reuse the water for other processes to reduce overall water consumption.

Explaining the treatment process, he points out that, depending on the water source and the impurities that need to be removed, in most cases the water purification process will involve five stages. These stages are pretreatment; chemical dosing; cartridge prefiltration; Reverse Osmosis membrane systems; as well as optional post treatment.

During the pretreatment stage, coarse solids and other large materials often found in raw wastewater are removed. “The removal of these materials is necessary to enhance the operation and maintenance of subsequent treatment units,” notes Du Plessis.

In the chemical dosing stage, there is an addition of any number of flocculants that remove the unwanted particles from treated water. The most common flocculants used in chemical dosing are; chlorine (in gas, liquid and granular form), ultraviolet, ozone, lime and soda ash.

The cartridge prefiltration is used as prefilters when particles in the untreated water could reduce the effectiveness or service life of another treatment device. For example, consider a situation where the untreated water is turbid (cloudy with tiny particles of sediment or other material) and contains an organic chemical.

The RO membrane systems stage reverse osmosis can/is be remove many types of molecules and ions from solutions and is used in both industrial processes and producing potable water. The result is the solute is retained on the pressurised side of the membrane and the pure solvent is allowed to pass to the other side.

The optional post treatment stage is the final step in the treatment of water. It is a method of adding a minimum level of chlorine into the water mainstream down to distribution. The purpose of it is to remove pathogenic microorganisms, which can cause a variety of diseases, and also to prevent the growth of harmful microorganisms by maintaining low levels of chlorine in pipelines and home plumbing.

According to du Plessis, technology determines the treatment time which can be instantaneous with membrane systems or a few hours with traditional chemical and biological treatment.

The chemical treatment involves sedimentation, anti-scalant and pathogenic treatment to produce water suitable for further processing and the biological treatment include aerobic or anaerobic treatment to reduce Biochemical Oxygen Demand (BOD) and Chemical Oxygen Demand (COD) to acceptable levels for further processing. The water can be recycled for reuse or discharged in a safe and acceptable condition.

Du Plessis elaborates on the effects that water that has not been treated properly may have on humans and equipment.

“The biggest risk is to human health, where heavy metals are not removed could to contaminants such as cysts and bacteria. The other risk is damage to equipment, calcium and magnesium can cause damage to boilers if no removed.”

Apart from the water purification treatment, there is also potable water purification which is the process of purifying water that is chemically and biologically safe to drink without the risk of causing health problems.

Du Plessis adds that this can include membrane, chemical or a combination of the treatments.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation