Distance measurement of melting bath levels and incandescent objects

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

IAS GmbH develop an innovative powerful cooling system for off-the-shelf microwave sensors – applications in pyrometallurgy for metal and glass industries

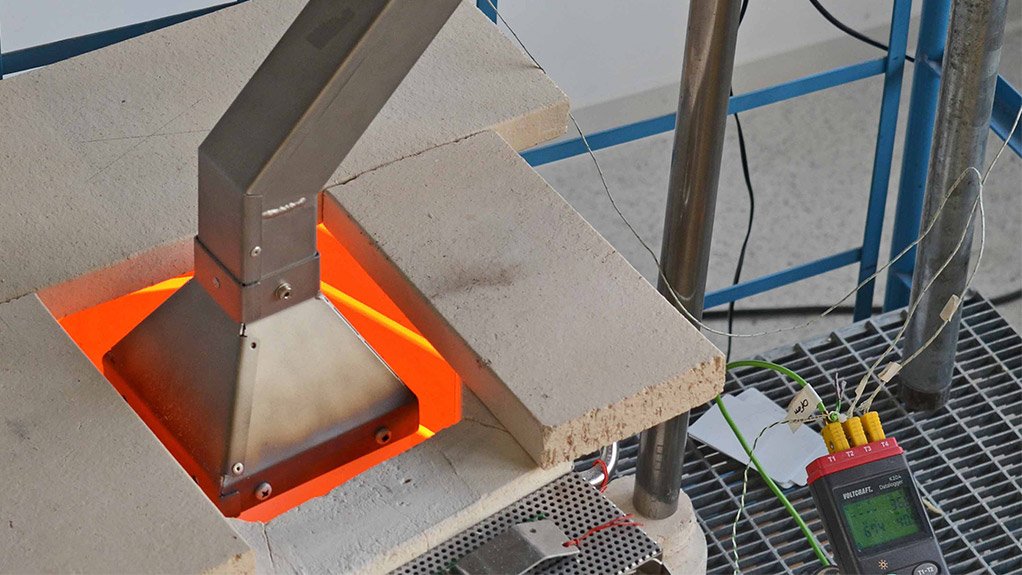

A cooled sensor system for high-temperature areas up to 800°C – this is the result of a development project by the company IAS GmbH from Weil der Stadt (near Stuttgart). The cooling system facilitates the use of off-the-shelf microwave sensors in high- temperature areas. Completely new approaches in pyrometallurgy for the metal and glass industry have now been made possible. The focus is on process optimization with regard to raw material and energy usage.

Monitoring the levels of molten metals and molten glass is a precarious issue. The same applies to level monitoring in casting channels, position control of incandescent semi-finished metal products, and controlling the metal bands in annealing furnaces. How can molten metal and glass, or hot components be measured and analysed? The sensor used in the IAS product operates according to the principle of radar technology in the high frequency microwave range. Target detection and positioning is achieved via radio waves and/or electromagnetic waves. This active transmitting and receiving process is the ideal application for the microwave high-temperature sensors.

Simple installation of the IAS cooling at long last makes the use of sensors reliable, low maintenance, and cost effective: Dissipation of heat encroaching the sensor system is achieved by heat pipes directly on the cooled sensor. The heat is conducted to the heat sink located on the opposite side at the back end of the housing. From the heat sink, the heat is dissipated to the environment. „It is now possible to use an absolute measurement sensor for distance measurement of melting bath levels and incandescent objects in hot, i.e. harsh, environments“, explains Steven Hartmann, Managing Director of IAS GmbH. A further advantage of microwave sensors compared to inductive sensors is the considerably higher range from sensor to object thus resulting in a significantly larger measurement area.

Installation outside the furnace – and also inside

By using a passive cooling system, the sensor can be installed outside the furnace. Depending on requirements, installation inside the furnace or inside casting channels is also possible. The innovation is that an active cooling fluid loop is not needed. An example to illustrate the advantage: For an installation outside a pressure controlled furnace, microwaves penetrate a gas-tight insulation plate mounted in the furnace insulation. Heat encroaching the sensor is thus greatly reduced compared with sensor installation directly in the furnace. At the same time, the operating life of the sensor is greatly increased. Mr. Hartmann: „Maintenance work can be carried out without stopping the process. Energy saving as a result of closed furnace operation is also worthy of mention.“

What happens when the sensor cannot be installed outside the furnace because of design reasons? Thanks to the IAS invention, installation of the sensor inside the furnace is now possible. The danger of leaking cooling fluid causing serious damage or injury in the event of a malfunction simply does not exist because the system is passively cooled.

Passively cooled system – with the highest reliability

A digital interface enables both the set-up of application specific parameters as well as addressing of the sensor. Retrieval of measurement data can be accomplished in either analog or digital mode. Whether internal temperature or sensitivity diminishment of the measurement because of fouling: Sensor specific parameters can be correspondingly read within the framework of Condition-Monitoring. Mr. Hartmann: „The cooling of off-the-shelf microwave sensors further optimizes the process in high-temperature areas – and furthermore, our product is suitable for all areas in connection with Industry 4.0“

The company IAS GmbH already have functioning prototypes that can reliably operate in an environment with a temperature of 800 °C. The series production of the system can be rapidly implemented following evaluation of several planned test systems in industrial environments. The cooling system has already been registered as patent. The project is supported by the Federal Ministry for Economic Affairs and Energy within the framework of the Central Innovation Programme for SMEs and it was implemented in cooperation with the Institute of Nuclear Technology and Energy Systems (IKE) at the University of Stuttgart.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation