Decarbonised iron production possible using sodium, company says

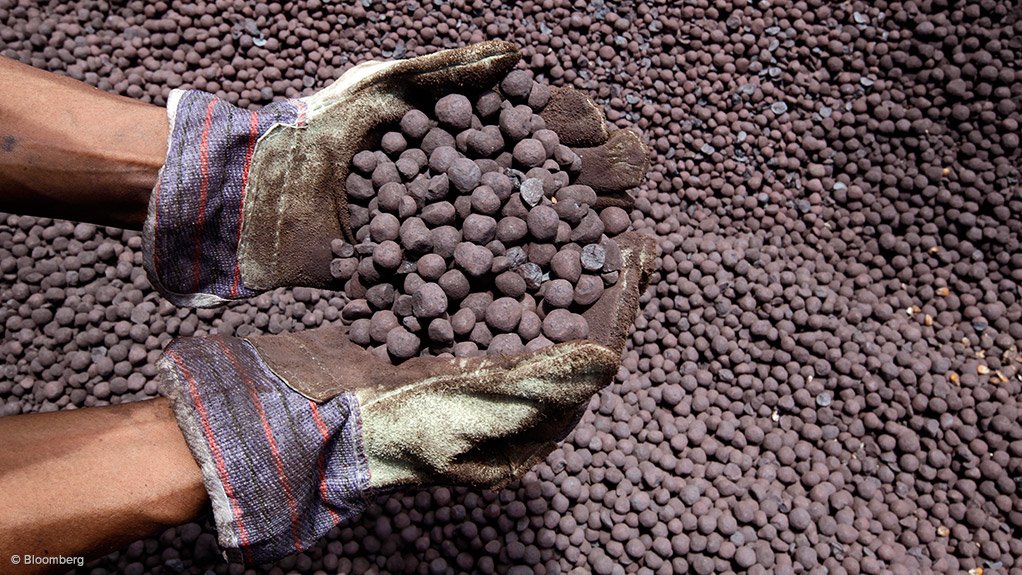

A new process being pioneered by energy companies such as Israel-based Helios and Netherlands-based Alkalium proposes the use of sodium metal rather than coal or hydrogen to refine iron-ore into direct reduced iron (DRI).

Traditionally, iron is beneficiated by mixing iron-ore fines with coal. The iron oxide (Fe2O3), when heated in a furnace, undergoes a chemical transformation whereby the oxygen molecules from the Fe2O3 bind with the carbon molecules in the coal, creating carbon dioxide (CO2) as a by-product and leaving pure iron behind.

The CO2 emissions are, no doubt, undesirable, as is the continued need to consume coal.

However, Alkalium CEO Rob Vasbinder tells Engineering News & Mining Weekly that his company has developed a process whereby Fe2O3 is mixed with pure sodium metal to create a spontaneous reaction without the need for pressure or a catalyst. This process can produce DRI without any harmful emissions.

The Alkalium iron process involves several steps.

1. The Natrolyzer

In the Natrolyzer, renewable electricity is used to separate sodium hydroxide (NaOH), otherwise known as caustic soda or lye, into sodium metal, oxygen and water (H2O) using an electrolysis process.

The oxygen is harmlessly released into the atmosphere, while the H2O is collected to be used in the Washer later on.

2. The Reducer

In the Reducer, the sodium metal is blended with iron-ore. During the reaction that follows, the oxygen molecules from the Fe2O3 bind with the sodium to form sodium oxide (Na2O), leaving pure iron behind.

No pressure or catalyst is required to facilitate this spontaneous reaction.

3. The Washer

The byproduct of Na2O is fed from the Reducer into the Washer, which adds H2O to the Na2O, where the hydrogen and oxygen atoms bond with the Na2O to result in the formation of NaOH.

Again, no pressure or catalyst is required to facilitate this spontaneous reaction.

The resulting NaOH is then fed back to the Natrolyzer, and the cycle is repeated.

The amount of sodium lost throughout the entire cycle is less than 1%, meaning that it can be used many times over before any additional NaOH supply is required.

The only electricity needed for the entire process is for the electrolysis stage, which can be powered by solar. In this way, no harmful emissions result from the process at any stage.

This entire process could easily be set up on site at an iron-ore mine, with a solar array installed to power the electrolysis. This way, green DRI can be produced on site, where sodium is used as a high-density, 4 kWh/kg energy carrier.

“What we're looking at here is producing DRI and decoupling it from the steelworks. It allows for the production of DRI either before you export it or even at the mine itself, using sodium.

“The process produces the DRI without the need for all the gas or the coal that is normally used to make iron. It's the most efficient way to do it,” Alkalium economic adviser Nick Thomas explains.

By exporting DRI as opposed to iron-ore, South African iron-ore producers could earn significantly more per tonne and could ship more at a time, while simultaneously contributing to a greener steel production process, he says.

“The important thing to realise is that the solar energy required to do this is significant, so the location of the solar panels is important.

“This would not be possible at the Port of Saldanha Bay or anywhere in Europe, nor would it be logical since iron-ore would still have to be transported instead of DRI. However, at an iron-ore mine in the middle of nowhere, it should be possible,” Thomas notes.

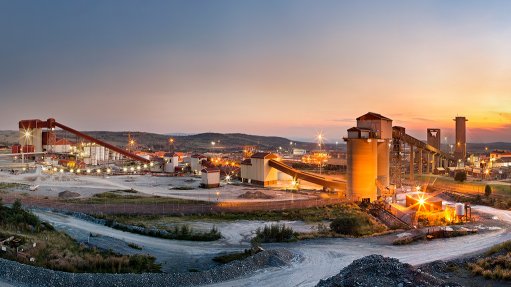

South Africa’s largest iron-ore producer Kumba Iron Ore, a subsidiary of diversified miner Anglo American, operates the Sishen and Kolomela mines in South Africa’s Northern Cape province, which has excellent solar resources. It transports the iron-ore over 861 km by rail to the deepwater Saldanha Bay port for export.

Thomas envisions a scenario whereby NaOH is continuously shipped from Saldanha Bay to Sishen, for example, in the empty rail wagons, to rapidly increase the amount of sodium metal being produced at the mine. This would be in addition to the NaOH being recycled from the Washer.

He points out that Helios has been developing a similar process in partnership with Anglo as a key investor.

However, while sodium is the sixth most common element on earth and is easily extracted from the abundant sodium chloride found in the ocean, Vasbinder bemoans that there are only a few factories globally that supply pure sodium metal. This is simply owing to the lack of demand, as pure sodium has, until now, only been useful in highly specialised chemical processes.

However, the market for NaOH is almost 800 times larger in production volume at about 83 000 000 t/y in 2022 and provides an ideal starting point for the Alkalium process.

Also the Alkalium process does not consume NaOH in the iron manufacturing process. It is continuously recycled, which means that DRI production factory would only have to buy it once, thereafter merely topping up its supply periodically to make up for small losses over time.

“You need a lot of sodium to make this technology work for the iron industry and the current sodium production industry can't cope with the demand. That would be the reason why companies have not really picked up on this,” Vasbinder explains.

For sodium-based DRI production to become viable at scale, sodium production would need to be amplified.

However, Vasbinder is confident that this will change when the Alkalium energy storage and transport solutions take off.

He notes that, when it comes to hydrogen, the required production levels also fall short, although it takes many more years to get hydrogen production realised than it does to get sodium production realised.

Moreover, hydrogen production and transport through traditional means is far more expensive than the sodium route.

“Since sodium as a reducing agent is new to the iron market, there is still a lot of research and development (R&D) that needs to take place. Iron producers are getting shy of the hydrogen route because it is arriving too late and is too expensive. However, the sodium route will give them a new R&D push.”

He notes that major steel producers, such as Tata Steel in the Netherlands, have resorted to using natural gas instead of coal and scrap metal rather than iron-ore to reduce their emissions because the hydrogen route is not viable in the short term.

“Sodium could be their saving grace,” Vasbinder claims.

ALKALIUM ENERGY PROCESS

In addition to being a solution for the production of green DRI, Vasbinder says solid metal sodium is also a potential solution to the global energy crisis.

Although much of the world is looking to hydrogen as a potential clean energy solution, one of the biggest problems with hydrogen is the cumbersome, complicated and expensive processes involved in transporting it.

When refined into solid metal form, NaOH can store up to 4 kWh/kg of energy, which Vasbinder says is equivalent to the energy storage capacity of ammonia, which is considered a major carrier for hydrogen.

“We think we have found a better energy storage route than anybody else has thought about, which is sodium metal. What’s more, it is available in 125 countries around the globe. So it has no geopolitical elements associated with it, and it is just one metal. There is no need for lithium or cobalt, for example,” he explains.

The energy storage solution requires the same Natrolyzer as discussed with the iron process, with the feedstock being NaOH and the output being sodium metal, oxygen and H2O.

To release the energy from sodium, H2O is introduced to solid sodium metal in Alkanium’s Alkalyzer, causing a spontaneous reaction without the need for pressure or a catalyst. This reaction creates pure hydrogen and NaOH.

The hydrogen is then captured and stored as fuel, while the NaOH is fed back into the Natrolyzer once more.

The major upside to this process is that the only substance needed to start it is solid NaOH, which can be recycled indefinitely.

Another significant advantage of this technology is that it can be used to produce hydrogen onsite, rather than having to transport it from afar using tankers, pipelines and have it be processed at liquefication and regassification plants.

The Alkalium technology can be scaled to any size required, from kW to GW, Vasbinder says.

He notes that South Africa is an ideal location for the green production of sodium metal through the electrolysis process owing to the significant solar resources in the country.

“The sodium metal market is now still a small market because it's a niche chemical. We want to expand it to become a global energy carrier competing with liquefied natural gas, coal and crude.

“We can very easily now store renewable energy into sodium and transport it from A to B because sodium’s energy density is high, and every country in the world can join in on its production,” Vasbinder says.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation