Decades Of Innovation Driving Weg Product Efficiency

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Africa has embraced the innovation that drives WEG products and services, with customers seeing value in constant technological improvement. Siegfried Kreutzfeld, CEO of the South African based Zest WEG Group, explains that WEG is quick to introduce its new products into the African market, sometimes even before launching elsewhere in the world.

Africa has embraced the innovation that drives WEG products and services, with customers seeing value in constant technological improvement.

Siegfried Kreutzfeld, CEO of the South African based Zest WEG Group, explains that WEG is quick to introduce its new products into the African market, sometimes even before launching elsewhere in the world.

“We pride ourselves on the significant investment we, as WEG, make in research and development,” Kreutzfeld says. “About 2,6% of our net revenue is ploughed back into continuous product improvement as well as new development. This keeps us at the cutting edge of technology.”

The result of this intense commitment to innovation is that 43,7% of all WEG products sold in 2018 were launched in the last five years. Another indicator is that Brazil-based WEG Group holds 174 patents that are used on its products.

Significantly, this has placed WEG among the thousand most innovative companies in the world, ranked by The Global Innovation 1000 of 2014. This world ranking evaluates the total R&D investments of each company, including the strategy, purpose and success of these investments.

“More than 35 years ago, we led the way in South Africa by introducing reliable high performance motors into the mining sector,” he says. “Today, we have a solid market share on the continent based on the trust we have built with our customers. This relationship makes it easier to introduce and test new WEG technologies in Africa.”

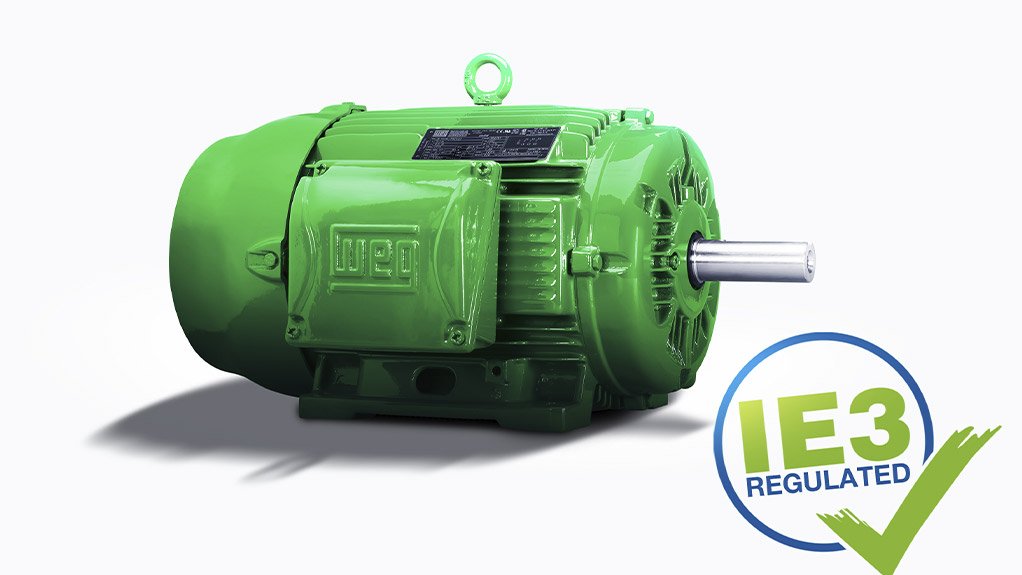

While continuously improving its products, WEG also closely monitors how they perform in the field, Kreutzfeld notes. “An indicator of the confidence we have in WEG technology is that we provide a five year warranty on WEG motors,” he says. “This is unique on the continent and difficult for competitors to match.”

WEG’s innovation and the market trust are paying dividends. Despite the country’s poor overall economic performance, Kreutzfeld says Zest WEG Group is targeting 15% growth with its high quality offerings.

Among the latest WEG technologies are energy-efficient IE3 motors which reduce electricity consumption, and the WEG CFW 11 Variable Speed Drive (VSD) which selects the best efficiency, again conserving energy and saving costs.

Kreutzfeld says that during 2019 a new series of WEG VSDs, specifically for mine fan applications, will be introduced to the market.

WEG’s innovative Motor Scan device is another important development, harnessing connectivity and the power of Industry 4.0 technology to monitor motor health. Attached to the motor itself, the WEG Motor Scan gathers vital data including vibration, temperature and running time. This is communicated wirelessly to a hand-held device or to WEG’s Internet of Things (IoT) platform.

“Extending electric motor life is going to be an important trend in the market, especially in the mining sector,” Kreutzfeld explains. “Only a decade ago mines expected less than two years of life from an electric motor, and we have been able to change that. Using Motor Scan will allow end users to optimise routine maintenance and extend motor life.”

Another technological innovation is the large WEG slipring motors considered ideal for the cement industry. Cement plants place high wear demands on electric motors, and WEG has developed features to address this challenge.

“We innovate by being close to our customers and seeing the problems they face,” he says. “You cannot pursue innovation without understanding customer applications and market trends.”

To drive this process, WEG established a Scientific and Technological Committee in 1998. This forum allows WEG’s engineering team to engage with five university specialists, three from abroad and two from Brazil. The forum meets every two years to discuss market trends, technology and innovation, and importantly how to apply this to WEG products.

“During this meeting, we share new concepts and products with the academic experts,” he says. “This collaboration has many mutual benefits. We gain ideas and feedback, and the universities can gather topics for their students to research.”

Inside WEG itself, there is a team focused on new product concepts and technologies. Kreutzfeld says many of these might remain in development for years, even decades, and are only commercialised in response to market trends.

“This pipeline of innovation is vital to meet changing customer needs and is what sets WEG apart,” Kreutzfeld concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation