South Africa has world class gas engine component reman skills

Metric Automotive Engineering operates a world class engine component reman facility in South Africa.

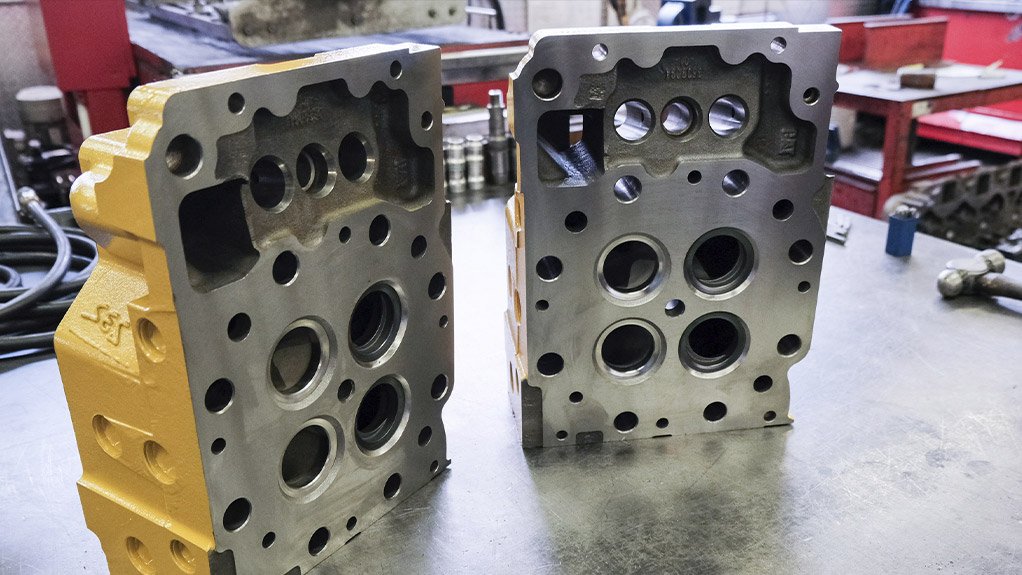

Remanufacturing gas engine components requires skills and cutting edge equipment. Metric Automotive Engineering has just this.

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Operators of gas engines, whether being used in natural gas applications or to generate power from landfill sites, have access to a world class component remanufacturing facility right here in South Africa. Metric Automotive Engineering has the requisite skills and cutting edge equipment needed to optimise the lifespan and reliability of these gas engines.

Leveraging gas as a power source is an exciting prospect for Africa, and offers not only reasonable costs but will have a lower environmental impact. While natural gas is generally a clean burning fuel, gas generated from landfill sites is considered a much harsher application for engines.

Andrew Yorke, operations director at Metric Automotive Engineering, says this is because it is difficult to control the level of contaminants in gas that emanate from landfill sites.

Yorke says that the relatively poor quality of gas requires advanced ignition monitoring systems in the engine. In addition, the wear rates remain high due to the highly abrasive post-combustion residue, despite filtering of the gas.

“This means that gas engines operating in these applications require more frequent maintenance and the service intervals will also be reduced,” he says. “As a comparison, with natural gas cylinder heads will need to be replaced every 20,000 to 30,000 hours, while with engines burning landfill gas attention will be required as early as every 5,000 hours.”

He notes that there is no real cause for concern as South Africa has a world class engine component remanufacturing capability in Metric Automotive Engineering. Ready access locally to the requisite skills and cutting edge equipment needed to optimise the lifespan and reliability of these gas engines is a major advantage to these industries, he says.

The company has been in operation for more than 50 years, with its decades of experience underpinning the remanufacturing of both diesel and gas engine components to meet the exacting original equipment manufacturer (OEM) standards.

Yorke says that Metric Automotive Engineering has already been conducting work for customers in the both the natural gas and landfill gas segments, where the generating capacity of the engines is usually between 1 MW and 10 MW.

The company also provides customers with service exchange units. This not only enhances efficiencies in the maintenance process and reduces downtime, it also allows customers to have remanufactured components such as cylinder head assemblies readily available when worn components need replacement.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation