New software solution for mine data analysis

The Booyco Electronics Asset Management System software suite helps mines process and evaluate data

A software suite from proximity detection solutions provider Booyco Electronics is set to transform the way mines process and evaluate captured data.

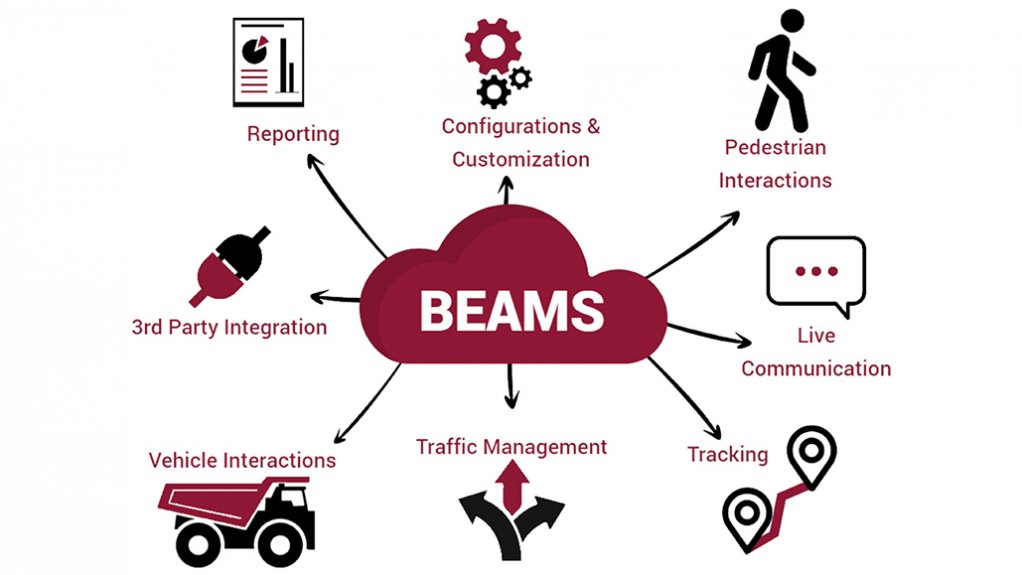

The Booyco Electronics Asset Management System (BEAMS) software centralises information from various sources, including a mine’s proximity detection system (PDS) assets data.

“BEAMS acts as a single source of information, a comprehensive hub that consolidates data from both our PDS and collision prevention system hardware and monitoring devices into a robust database,” explains Booyco Electronics CEO Anton Lourens.

The Web-based application links the PDS hardware products and monitoring devices and can also transform large amounts of data into a single, comprehensible and manageable stream. This provides insight into various facets of the mining operation, helping to increase safety and productivity levels.

BEAMS is able to analyse data to detect patterns which could indicate unsafe behaviour. This enables mines to identify potential risks and design appropriate interventions.

“BEAMS helps paint a comprehensive picture of the working environment, uncovering operational issues that were previously unknown,” Lourens emphasises. By quantifying the working environment and its interactions, potential risks and bottlenecks can be identified, managed and reduced, ultimately leading to a significant boost in productivity.

BEAMS can feed a digital twin model with real-time, accurate information about the state of the mine's assets and the environment. This allows for predictive modelling, risk analysis and improved decision-making.

The software solution is designed for easy implementation and adaptability and can conform to various information and infrastructure environments, which aims to ensure seamless integration into existing systems and workflows.

In addition to improving safety and productivity, BEAMS can integrate with lamp room management systems in underground mines. This feature helps ensure legal compliance with lamp room requirements and helps mines to effectively locate critical safety equipment such as lamps, self-contained self-rescuers and gas instrumentation.

The solution can be configured to meet the unique needs of each user, offering a standard set of reports or providing customised reporting to address specific requirements.

“By centralising information, detecting unsafe interaction patterns and providing easy implementation, adaptability, integration and customisable reporting, [BEAMS] is redefining safety standards and productivity levels in the mining industry,” Lourens concludes.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation