Jaguar Land Rover trials world-first digital supply chain for leather using blockchain technology

Jaguar Land Rover has trialled the use of secure blockchain technology “to ensure full transparency within a sustainable leather supply chain”.

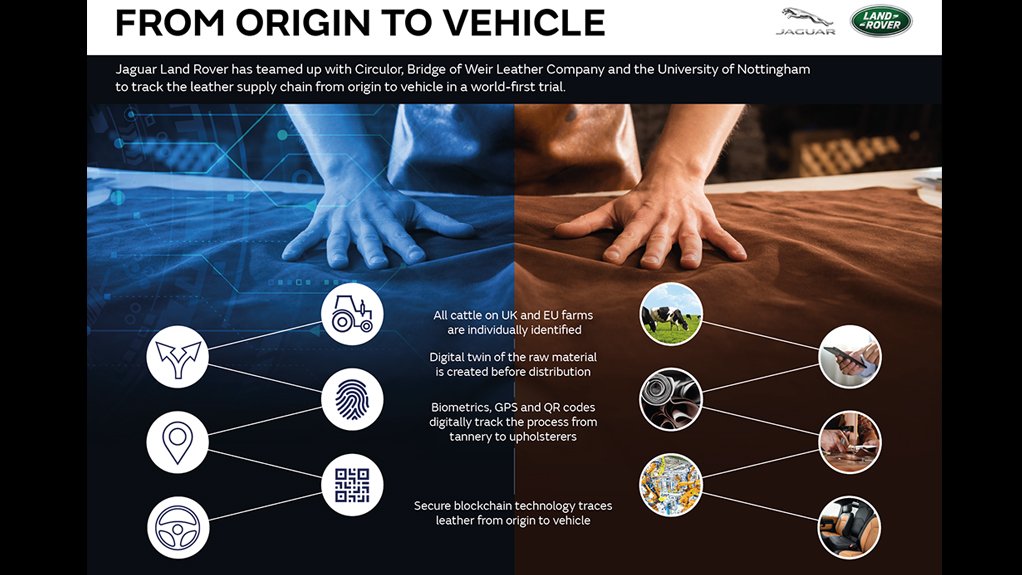

In the world-first, the British automaker partnered with supply chain traceability provider Circulor, UK leather manufacturer Bridge of Weir Leather Company, and the University of Nottingham to trial the use of traceability technology in the leather supply chain.

As well as tracking compliance, the digital process enabled Jaguar Land Rover to assess the carbon footprint of its leather supply network, working with Bridge of Weir Leather Company to trace its lowest carbon leather from farm to finished article.

Jaguar Land Rover says it is “committed to offering customers more sustainable and responsible material choices for their vehicle interiors”, such as the natural fibre Eucalyptus textile interior available on Range Rover Evoque, and Kvadrat – a wool blend textile that is paired with a suede cloth made from 53 recycled plastic bottles per vehicle – available on the Evoque, Range Rover Velar and Jaguar’s all-electric I-Pace.

As part of the Innovate UK-funded research, a ‘digital twin’ of the raw material was created, allowing its progress to be tracked through the leather supply chain simultaneously in the real world and digitally.

A combination of GPS data, biometrics and QR codes was used to digitally verify the movement of leather at every step of the process using blockchain technology.

Defining the verification process has created a repeatable blueprint for tracing a single piece of leather at every stage.

This can be used across Jaguar Land Rover’s global supply chain and by other industries that rely on leather, such as fashion and footwear.

“We are currently restructuring our supply chain as part of our Reimagine strategy, with a focus on transparency and sustainability,” says Jaguar Land Rover supply chain executive director Dave Owen.

“The outcome from this world-first trial will allow us to further improve the sustainability of the leather supply chain around the globe, ensuring the complete traceability of raw materials from origin to vehicle.

“This is one step in our journey to net-zero carbon emissions across our supply chain, products and operations by 2039, enabled by leading-edge digital capabilities.”

Through InMotion, Jaguar Land Rover’s venture capital and mobility services arm, the company previously announced an investment in Circulor, allowing the company to source premium materials with greater transparency as to the provenance, welfare, and compliance of suppliers throughout its networks.

Circulor is already using blockchain to improve the traceability of minerals used for electric vehicle batteries.

Circulor provides traceability-as-a-service to verify responsible sourcing, underpin effective recycling and attribute carbon footprint and other impact metrics to the flow of materials.

Blockchain technology is impossible to modify or tamper with, giving customers greater confidence that the sustainable supply chain is authentic, and all materials have been sustainably sourced.

“In partnership with Jaguar Land Rover and the University of Nottingham, we believe there is a clear opportunity to implement blockchain technology to enhance the world-leading standards of traceability and transparency that exist within UK agriculture and its Cattle Tracing Scheme,” says Scottish Leather Group innovation and sustainability director Dr Warren Bowden.

“At Bridge of Weir, we see the potential to create carbon-positive leather – if we source from local farms where the livestock is grass-fed, where there is no deforestation, and if we couple this responsible approach to sourcing with ongoing innovation to create zero-carbon and zero-waste manufacturing processes.

“The blockchain technology developed in this trial will enable each stage in the process, and the entire leather supply chain, to be accurately tracked and measured.”

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation