Impco’s automated side wall drill rig increases safety, reduces cycle times

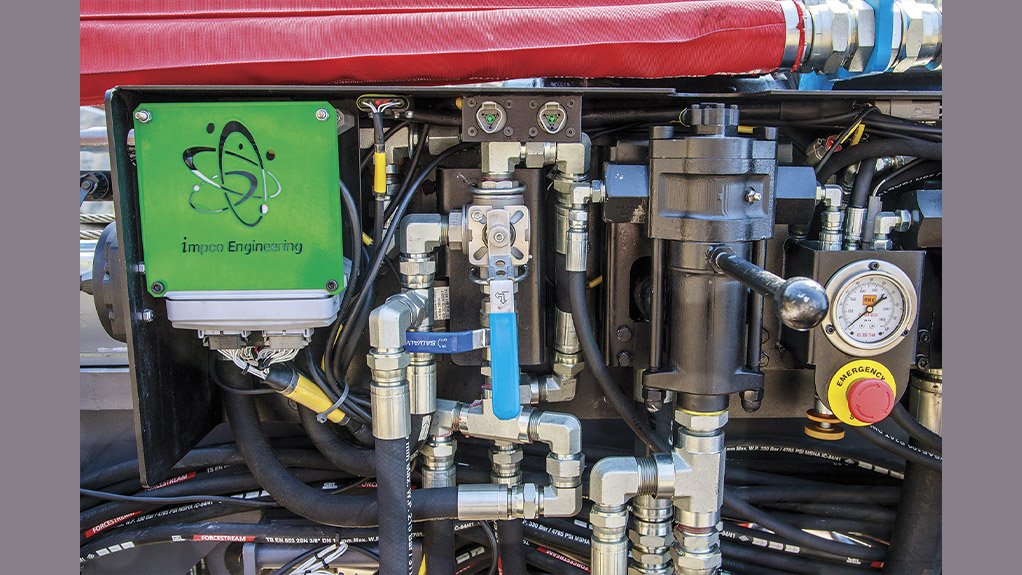

In introducing a safer, speedier, more accurate and energy efficient solution for blind shaft boring operations, Rosslyn-based Impco Engineering has delivered its latest automated innovation, called the Side Wall Rig, to the South American and US markets.

This auxiliary piece of equipment adds to the company’s Jumbo S140 drifter drill rig. It provides an automated alternative to manual side-wall drilling and support – a cycle of which, at best, takes between 12 and 22 hours to complete, while the Side Wall Rig can achieve the same result in 3.5 hours.

Notably, the operator of the rig can choose to operate the Side Wall Rig manually or continue automatedly.

About seven operators would traditionally use hand-boring machines in a 7-m-wide shaft, whereas the Impco Side Wall Rig reduces the operator requirement to three or four people underground – making side wall drilling safer and more accurate while ensuring lower labour costs.

The speed of boring a 1.5 m hole is reduced to mere minutes with the impressive 110-piston machine.

Impco MD Kobus Duvenage explains manual hand-boring often results in bent or broken parts, with such costs and delays eliminated with the Side Wall Rig as it uses load sensor technology to adjust drilling angles and speed during operation.

This software is also used on the Jumbo drill rig to detect ground conditions and adjust drilling accordingly. It is capable of monitoring boring speed and notifying operators of necessary preventative maintenance actions.

Importantly, the Side Wall Rig has an emergency stop function when required.

Impco mechanical engineer Dylan Duvenage notes the Side Wall Rig also has the advantage of allowing access to heights in the shaft bottom. He explains an operator can access the whole advance on the side wall, meaning mesh can be installed on the whole length of the shutter, which is typically 3.5 m, as well as 1.8 m to 2.4 m split sets for support.

He adds Impco specifically designed new valves to control the Jumbo drifter through software, to allow for switching between the automated and manual modes of operation. “For air-driven equipment, particularly of this size, there were no valves in the market capable of switching quickly while remaining robust for the mining industry.”

Dylan Duvenage highlights Impco spends about two weeks with new customers for on-site commissioning of its equipment and to train operators on its features and fault-finding.

Elaborating on more features of the Side Wall Rig, Dylan Duvenage explains it has three levels of redundancy, whereby operators can either operate machinery in a remote-controlled manner, a wired remote-controlled manner, or mechanically.

“A lot of systems need to fail for the machine to stop working,” he emphasises, adding that all features can be operated pneumatically, especially when the remote batteries are being charged.

To allow for global connectivity, the Side Wall Rig uses a CS100 module with a universal SIM card that can connect to any local network.

This also enables Impco to monitor the performance of all its installed rigs, send remote updates and offer drill optimising advice.

Moreover, Kobus Duvenage shares the company is in the process of developing a rig kit to help dig and shape the station levels that a mine would typically have at every 30 m below ground.

To this end, Impco aims to offer a complete trackless blind shaft boring solution.

With a production time of between four and five months, compared with its peers that often take 18 months to manufacture blind shaft boring equipment, this key differentiating factor of the company is supported by a specialised in-house team of engineers and facilities where it manufactures all the components and parts required for the Side Wall Rig and Jumbo drill rig.

For example, Impco’s record for taking apart the 15 000 components of a drill rig and undertaking refurbishing is 18 days.

Owing to the company’s use of standardised components, parts and common consumables, it enables Impco to keep high levels of stock inventory and ensure parts availability.

Dylan Duvenage points out the Side Wall Rig has been designed with low noise pollution in mind, with industry-leading noise level performance. He explains a traditional pneumatic drill operates at 118 dB, while Impco’s equipment operates at 101 dB.

To better accommodate its manufacturing requirements, Impco is in the process of moving its head office and facilities to another site in Rosslyn, which will allow for 4 000 m2 of space.

Kobus Duvenage expects the move to be complete in the first week of October.

Commenting on why automated and energy efficient products and equipment have become necessary in the mining industry, Kobus Duvenage explains all mining companies are rightly focused on achieving zero harm and therefore reducing the amount of people underground, particularly since shaft boring is the most dangerous part of mining.

Additionally, to ensure global competitiveness, mining companies have to opt for lowest cost, highest efficiency options.

Touching on the South African market, the Impco experts agree that the market for shaft boring has been quiet in recent years, however, they remain optimistic about the market picking up soon, especially as many shafts in the industry are reaching the end of their lives.

Impco is confident that its tried and tested automated Side Wall Rig with reduced cycle time and increased safety will continue making its mark in the global mining industry.

Tel: 012 541 0932

Email: kobus@Impco.co.za

Email: dylan@impco.co.za

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation