Green hydrogen-to-ammonia project, Namibia – update

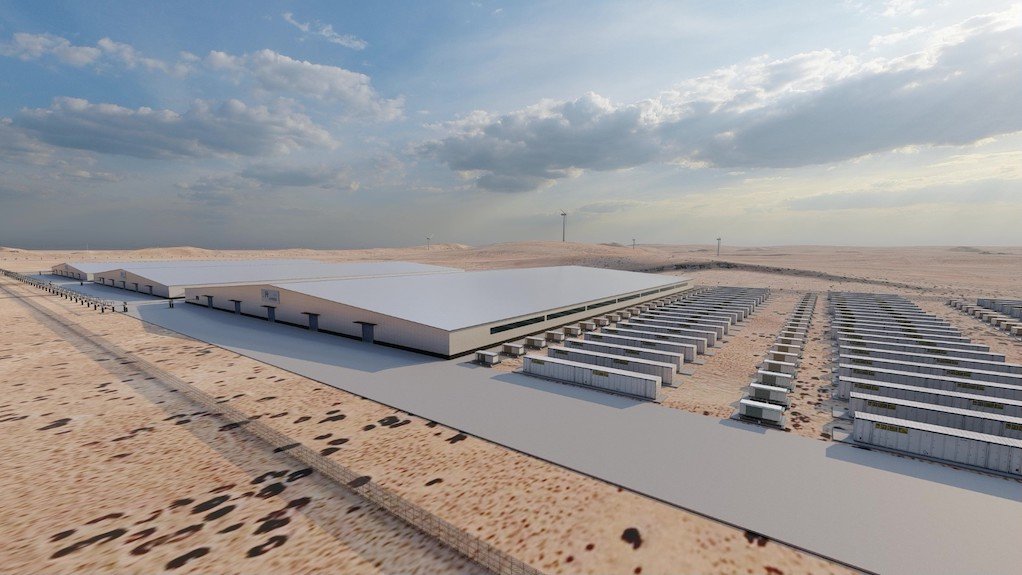

Photo by HYPHEN Hydrogen Energy

Name of the Project

Green hydrogen-to-ammonia project.

Location

Tsau //Khaeb National Park, near Luderitz, in Namibia.

Project Owner/s

HYPHEN Hydrogen Energy has been appointed as the preferred bidder to develop the project. It will operate the project for a 40-year period, following the conclusion of the feasibility study and sign-off from the Namibia government.

HYPHEN is a joint venture between Nicholas Holdings, a strategic investment and infrastructure project developer, and ENERTRAG South Africa.

Project Description

The development of Namibia’s first large-scale vertically integrated green hydrogen project will be completed in phases.

Phase 1 will create 2 GW of renewable electricity generation capacity to produce green hydrogen for conversion into green ammonia. This phase aims to produce 125 000 t/y of green hydrogen, to be further processed into 700 000 t/y of green ammonia for export to Europe.

After Phase 2, the HYPHEN project will possess solar and wind electricity generation capacity of nearly 6 GW and 3 GW of electrolysis, which will yield 300 000 t/y of hydrogen, which translates into 1.7-million tons of green ammonia.

Potential Job Creation

About 15 000 direct jobs will be created during the four-year construction of both phases, with a further 3 000 permanent jobs to be created during the operational phase. More than 90% of these jobs are expected to be filled by Namibians.

Capital Expenditure

$9.4-billion. The first phase of the project will cost about $4.4-billion.

Planned Start/End Date

The first phase is expected to enter production in 2026.

Latest Developments

The preferred bidder for thew project is aiming to conclude an implementation agreement with government by August, paving the way for a full-scale feasibility study for the eventual implementation of the project.

The implementation agreement would signal the formal contract award and would start he feasibility-study phase.

Speaking at the Namibian pavilion at the World Economic Forum, in Davos, Switzerland, held in June, HYPHEN CEO Marco Raffinetti indicated that, following pre-environmental assessment phase studies and community engagements, Hyphen was gearing up for the feasibility study and was aiming to achieve financial close by the third quarter of 2024.

This would allow for the project to start mobilisation and construction in early 2025, targeting a two-year build and first gas at the end of 2026, and immediately proceeding to the second phase without demobilising the construction team.

Raffinetti has said that the rapid implementation is being supported by the greenfield approach that has been adopted by Namibia, which views the project as the start of a large-scale green hydrogen export industry.

The approach is premised on a common user infrastructure commercial and technical design to facilitate further green hydrogen projects in the earmarked zone, located in the Tsau//Khaeb National Park.

The area has solar resources of up to 2 800 full-load hours a year and average wind speeds of 10 m/s, equivalent to offshore wind speeds in Europe.

ENERTRAG director Dr Tobias Bischof-Niemz has said that the approach being adopted by government provides for “rapid scalability” beyond the Hyphen development and has the potential to lay the foundation for the production of three-million tons a year of hydrogen from Tsau//Khaeb.

The common infrastructure includes pipelines for desalinated water, return brine, green hydrogen and ammonia, as well as port facilities and transmission lines to transport surplus renewable electricity into the Southern African Power Pool.

However, Bischof-Niemz has said there is potential for Namibia to produce 15-million tons of hydrogen a year or about 5% of global hydrogen demand for tradable hydrogen-based products by 2050.

At such a scale (150 GW of electrolysers and 250 GW of renewable electricity), Namibia’s entire energy sector will not only be fully decarbonised but could also support the efficient decarbonisation of hydrogen importers, as less wind, solar and electrolyser capacity would be required for the same level of output.

Seaborne exports would likely take the form of easily tradeable and transportable products, such as ammonia and methanol, while direct hydrogen could be supplied by pipeline to South Africa to produce products, such as green iron or steel, on the country’s West Coast, and synthetic fuels and chemicals inland, at Secunda.

The surplus electricity produced could also support the decarbonisation of South Africa’s electricity sector and improve security of supply to the rest of the Southern Africa region.

Namibia also has its own plans to industrialise form the platform created by green hydrogen and is assessing various downstream opportunities in steelmaking, ore reduction and synfuels production, as well as other electricity-intensive industries.

Interest from upstream renewable and electrolyser component firms are also likely, owing to the scale of the investment expected, with the possibility of about 200 000 permanent jobs being created in the wind and solar sectors.

Key Contracts, Suppliers and Consultants

None stated.

Contact Details for Project Information

HYPHEN Energy, email info@hyphenafrica.com

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation