Decentralised drive technology boosts production

A decentralised drive technology system is said to offer key industries the ability to save on operating costs, while providing the latest in energy efficiency technology.

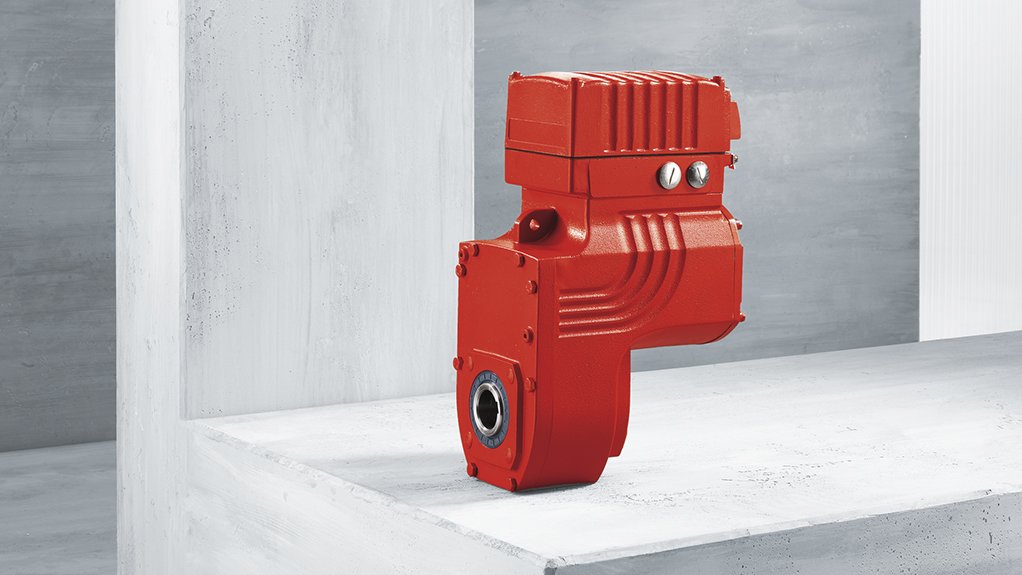

MOVIGEAR from SEW-EURODRIVE is a mechatronic drive system that is particularly suited to horizontal material-handling technologies. The drive electronics, motor and gear unit are combined in a mechatronic drive system, saving on cabling, installation and maintenance costs owing to its compact size.

The system is particularly suited to the food, beverage and small manufacturing industries, offering a smooth surface design based on local hygiene design guidelines and helping eliminate the need for additional fans, as it uses a surface cooling process. The units can also be specified to withstanding high-pressure washing.

"Fifty-three of our cutting edge MOVIGEAR units have been installed over a six-week period at a local bottling plant in Gauteng,“ says SEW-EURODRIVE sales manager Willem Strydom. "Our client was looking for technology that would enhance the plant‘s high production output, while providing cost and energy efficiencies across their conveyor systems."

Strydom added that the solution offers a sustainable and substantial reduction in carbon dioxide emissions, achieving up to 38% in energy savings on this specific project. The system reduces reactive power consumption compared to previous technology which operates directly on the supply system, ensuring a rapid return on investment. The sealed unit is also designed to reduce maintenance and operational costs, with oil analysis required only once every three to four years.

Additional advantages of the system include:

- The single line network principle means that only one cable needs to be installed for energy and information transfer

- Simplified system planning and design

- Fewer variants, as a result of a wider speed range and universal mounting position

- Lower storage costs

- High degree of protection

- No air, dirt or bacteria swirls

- Reduced energy costs, as a result of high efficiency of all components

- Systematic development of all components means improved reliability

- Reduces total and operating costs of the materials handling system

- Built-in Profinet communications protocol reduces the need for extra topology as there are fewer moving parts

"MOVIGEAR has proven to be highly reliable. Across clients in Europe we have seen significant benefits gained from the inclusion of the solution. A large bottling plant was able to boost production to 60 000 bottles per hour, while a beverage packaging plant was able to drive savings through energy efficiency. In South Africa, SEW-EURODRIVE is confident that this solution will continue to provide impressive cost, production and energy efficiencies for our customers across key sectors,“ concluded Strydom.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation