Afri-Tech’s Power Nozzle readying for intra-Africa export

Krugersdorp-based Afri-Tech Mining Supplies’ award-winning Power Nozzle is destined for export to Ghana, Mali, Tanzania, Botswana and Namibia before mid-year, with at least ten other sub-Saharan African countries expected to be export destinations by the end of the year.

The company already exports its range of high-quality screen cloths and ancillaries for belt presses, vacuum belt filters and linear screens into the rest of Africa and was acknowledged at the 2023 South African Capital Equipment Export Council Exporter of the Year Awards in November, where it won Exporter of the Year Africa with a turnover between R25-million and R50-million.

Afri-Tech MD Richard Arends says the award indicates that the mining industry recognises the company as a major player.

“We are immensely proud of our achievement and grateful to the entire Afri-Tech team which is able to identify new market opportunities for our expanding product offering.”

The Power Nozzle is the latest addition to the company’s portfolio and was introduced in 2018 after about five years of development. That same year, Afri-Tech’s new spray nozzle received the Overall Innovation Award at Electra Mining Africa, boasts Arends.

“Our design has been patented, and no equal or competing copy exists. However, we constantly monitor the performance of our different designs, using feedback from customers and our own observations to ensure continuous improvement. The result is a unique product that is proving itself on more and more sites and in an expanding range of applications.”

Exceeding Expectations

While the Power Nozzle is a niche product, Afri-Tech has realised that the market is much larger than the company initially anticipated, explains Arends.

The results of a recent laboratory-style test series analysing and recording the capabilities of the nozzles have proven that the product’s performance exceeds even current claims, highlights Arends.

“No other spray nozzle can do what it does: it auto-unblocks, saves wash water, reduces material use, is user-friendly and practically maintenance free. Thereby, customers’ site teams are free to perform other work. The production stoppages needed to unblock old generation nozzles are also a thing of the past, enabling screen units to operate for longer periods.”

The Power Nozzle will benefit any screening, washing, fines-removal, material-retrieval and screen-cleaning application globally, he highlights.

The product is achieving significant results on coal wash plants – yielding more than 80% magnetite savings – in diamond plants – reducing ferrosilicon consumption by more than 75% – and on tailings plants, where the nozzles increase fines recovery by factors and decreases wash-water requirements to achieve other savings.

Linear screens at mineral sands sites are also producing substantially cleaner and dryer product, while carbon and trash washing screens are cleaner and highly efficient where Power Nozzles have been installed, adds Arends.

“Additionally, a remarkably pure oversize material stream was achieved at one of our flagship trials for a major platinum producer, owing to a Power Nozzle-equipped vibrating screen.”

New Interest

The Power Nozzle’s benefits have attracted the attention of one of the world’s largest diamond companies. Successful trials were completed, and Afri-Tech is now awaiting a full roll-out.

New agreements have also been finalised to install and trial the product at various local coal producers, with the company receiving an order this month from the largest local coal producer for a large-scale roll-out.

“We are also proceeding with trials at a large chrome company located close to our manufacturing facilities. The trial will involve the installation of a Power Nozzle system with an air supply plant on one of eight large vibrating screens.”

In addition, Afri-Tech has started discussing a trial at a major iron-ore miner based in one of the harshest regions of South Africa.

“We are confident that these trials will all be successful and that we will receive orders to install Power Nozzles for these customers in future,” states Arends.

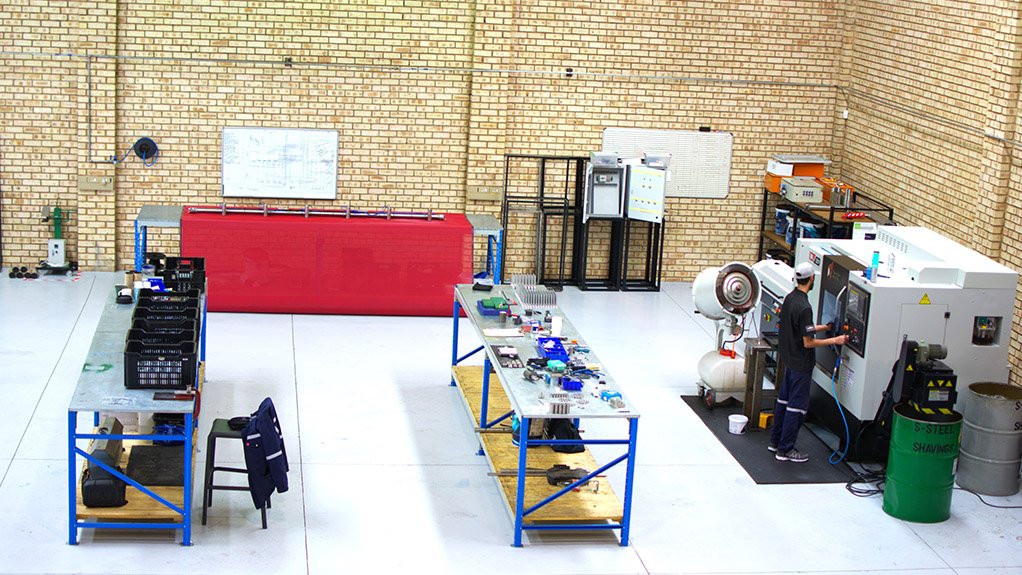

Afri-Tech can manufacture 300 units a month but expects this figure to increase to more than 500 units once the company finalises an enhancement programme initiated in December last year.

“The use of drilling jigs will increase our throughput and our already high levels of quality,” says Arends.

The main Power Nozzle components are manufactured from high-quality SS304 and will withstand normal corrosive conditions. Units have also been supplied in SS316 to accommodate operation in a high-chloride environment.

“Although we have not manufactured units in duplex materials (such as 2205 or 904) yet, we can and will do so if the specific need arises,” emphasises Arends.

Consistent quality is ensured by the managers of Afri-Tech’s manufacturing teams who are well-versed in ISO principles.

Each component, from raw material to the tested end-product, passes through many hands and checks, and has a unique serial number that allows for complete traceability.

“The pride that we all take in each step, and the finished project, is evident,” concludes Arends.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation