Sweet coating solutions for the sugar industry from Thermaspray

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Thermaspray, South Africa’s surface engineering and thermal spray coating technology specialist, offers a range of high quality coating techniques that assist the sugar industry in reducing maintenance costs by protecting both new and worn equipment parts and components against abrasive, adhesive, erosive and corrosive degradation.

Maintenance costs for the multiple-process sugar industry which includes the crushing, refining and packing of cane and beet sugar can make up as much as ten percent of the value of goods produced. Equipment maintenance as a direct result of abrasion, adhesion, erosion and corrosion leading to rapid wear and corrosion and subsequently expensive downtime can account for up to one third of plant maintenance costs, including replacement and/or repairs.

Thermaspray Managing Director, Dr. Jan Lourens, notes the importance of using a specialist coating company like Thermaspray. “As a DQS ISO 9001 Quality Management and Eskom level 1 certified company with close to 20 years’ experience in wear- and corrosion-resistant thermal spray coatings, we possess the necessary capabilities and knowledge of the correct coating techniques and applications using best practices as well as quality control of coating processes that are fundamental to ensuring successful results.

The excellent protection offered by our superior quality, highly dependable coating solutions against surface wear and corrosion delivers numerous cost saving benefits including the enhancement of equipment lifespan, a reduction in downtime, replacement and maintenance costs, and improved equipment and plant uptime, productivity and production.”

Methods applied by Thermaspray to overcome abrasion, adhesion, erosion and corrosion specifically in the sugar industry include:

- Thermal Spraying, a generic term used to define a group of processes that deposit fine metallic or non-metallic materials onto a prepared substrate to form a coating. The coating material may be in powder, rod or wire form. The different processes include:

- High Velocity Oxy-Fuel (HVOF): Operates on a continuous steady-state basis with

continuous powder feed. Thermaspray offers two processes - gas and liquid fuelled.

- Wire Arc Spraying (Also known as twin-wire arc spray process). Direct current (DC) electric arc is used to melt the feedstock with compressed air behind the arc atomising the molten material. Higher thermal efficiency is achieved as wires are melted directly. Coatings are coarse with higher porosity.

- Powder Plasma Spraying: Plasma (4th state of matter) consists of neutral and positive atoms and free electrons. Plasma gasses are heated as they ionise in the arc and high degree of melting and relatively high particle velocities are achieved. Finely structured coatings with high adhesion strength.

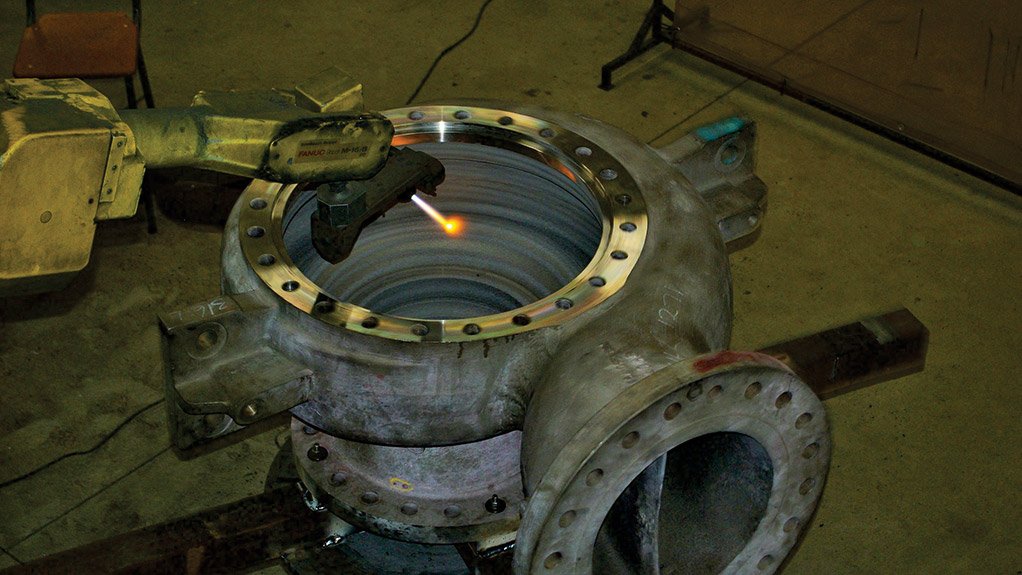

- Plasma Transferred Arc (PTA) welding and hardfacing process - a versatile method of depositing high quality metallurgically fused deposits on relatively low cost substrates.

• Polymer Applications

- Plasma Coatings (Non-Stick and Traction Coatings): Thermaspray has undertaken a

strategic partnership with Plasma Coatings in the USA to offer the South African market a new range of surface technologies and coatings to tackle the sugar, food, printing and packaging, tyre and rubber, paper and pulp, fempro/diaper and many more industries.

These coatings are designed to solve many of the above industries’ problems resulting in reduced maintenance, higher outputs and an increase in cost savings. These coatings combine the advantages of thermal spray (metal base) coatings with polymer top coatings to offer benefits of wear resistance, slip and traction. These coatings can be applied to aluminium, steel, stainless steel, tool steel, copper, ceramics as well as synthetic materials.

- Diamant Metalplastic (Polymeric Solutions): Thermaspray is the exclusive Southern

African representative of German-based DIAMANT Metallplastic GmbH. DIAMANT Metallplastic offers the metalworking industry high-quality polymeric solutions to restore functionality to castings, thereby significantly reduce scrap. The DIAMANT polymeric solution includes products for impregnating and sealing leakages, repair of blow holes and surface treatments as well as wear protection and services.

Typical applications in sugar industry include knife and trash plate replacement components in sugar mill, shredder hammers, crushers rolls, scrapers, pump casings, conveyor screws, valves covers, flanges and bearings and bearing journals.

Thermaspray, in a joint venture with Cape Town-based Surcotec, offers an extensive portfolio of engineering and thermal spray coating solutions that extend component life cycles to assist OEM and end-user clients across southern Africa in reducing costs and increasing production.

The companies’ world-class quality wear- and corrosion-resistant thermal spray coatings, Plasma Transferred Arc (PTA) cladding and Polymer coatings (in partnership with Plasma Coatings USA and DIAMANT Metalplastic Germany) are augmented by a host of specialised allied services.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation