Slurry density measurement and percent solids made easy using gas pycnometry

Slurry density measurement and percent solids made easy using gas pycnometry

The variety of industrial applications for different slurries necessitates a reliable method for evaluating the density of these unique mixtures. Accurate and repeatable density measurements can be performed using the Anton Paar Ultrapyc series gas pycnometers. In addition, the percentage of solids in a slurry can be easily determined from gas pycnometry measurements.

Introduction

A slurry is a mixture of dense solids suspended in a liquid. Slurries are used in a wide variety of applications, including:

- Batteries

- Cement/Concrete

- Ceramics

- Many others

Density is an important slurry property that is affected by the amount of solid suspended in the liquid. Measuring the density of a two-component system is easily handled using gas pycnometry. In particular, the Ultrapyc series gas pycnometers is ideally suited for slurry density measurement. Because there is usually some vapor pressure coming from the liquid component of the slurry, the Ultrapyc PowderProtect option to expand gas from the reference chamber into the sample chamber reduces the effect of any vapor pressure and leads to accurate density measurements. Finally, with density measurements on the individual components of the slurry and on the slurry itself, the percent of solids in the slurry can be easily computed.

Density Measurement

While gas pycnometry is best suited for solid skeletal density measurements, experimental parameters can be optimised for slurries and/or liquids that have some vapor pressure. To illustrate the use of the Ultrapyc 5000 for these types of measurements, the density of distilled water was measured, as water is often the liquid component of a slurry and its density is well-known for comparison purposes.

| Table 1: Recommended measurement parameters for slurries |

| Parameter | Setting |

| Cell size | Large |

| Gas type | Helium |

| Target pressure | 18 psig |

| Flow direction mode | Reference first |

| Equilibration | Fixed time, 0.33 min |

| Flow mode | Monolith |

| Preparation mode | Flow, 1 min |

| End mode / Finish Criteria | Better than 0.01% |

| Maximum runs | 10 |

| Runs to average | 3 |

The recommended experimental parameters for these measurements are given in Table 1. A high target pressure, short, fixed equilibration time, and short flow purge minimise the effect of any vapor pressure from the sample. Most notably, the Ultrapyc series’ bi-directionality (PowderProtect) feature for gas expansion allows the user to further minimise vapor pressure effects and obtain the most accurate liquid/slurry density measurement. Expansion (flow direction mode) from the reference chamber to the sample chamber should be used. The Ultrapyc 5000 was temperature controlled to 20 0C for the measurements. Results for three repeat density measurements are shown in Table 2. The experiment was performed using both expansion directions. The measured water density from the reference to sample chamber expansion is in excellent agreement with the known density of water at 20 0C, 0.9982 cm3/g.

| Table 2: Water density measurement |

| Mode: Reference first | Mode: Sample first | |

| Density (cm3/g) | Density (cm3/g) | |

| 1 | 0.9982 | 1.0004 |

| 2 | 0.9980 | 1.0006 |

| 3 | 0.9979 | 1.0005 |

| Average | 0.9980 | 1.0005 |

| Std dev | 0.000153 | 0.00100 |

Percent Solids in a Slurry

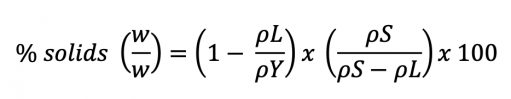

If the individual densities of the solid and the liquid in a slurry are known or measured, the percentage of solids by mass can be calculated from the density of the slurry. To demonstrate, a series of clay/water slurries of known compositions were made and the density measured. The density measurements on the eight different slurries were analysed using the settings recommended above. The density of the liquid (water) and the solid (clay) were also measured using the same instrument settings. The density of clay was found to be 2.6576 cm3/g and the density of water was found to be 0.9966 cm3/g. The densities obtained for the slurries are given in Table 3. To calculate the percent solids in the slurry, the following equation was used:

where ρS is the density of the solid, ρL is the density of the liquid, and ρY is the density of the slurry.

| Table 3: Formulated and calculate % solid in slurries with measured densities |

| % solids formulated | Measured density (cm3/g) | % solids calculated |

| 41.45 | 1.3459 | 41.52 |

| 33.9 | 1.2682 | 34.27 |

| 26.30 | 1.1977 | 26.66 |

| 17.75 | 1.1282 | 17.96 |

| 15.22 | 1.1001 | 15.05 |

| 10.57 | 1.0688 | 10.81 |

| 6.41 | 1.0388 | 6.50 |

| 2.52 | 1.0121 | 2.45 |

Excellent agreement was found between the formulated and calculated values. This principle of determining the percentage component of a two-component system can also be extended. The basic requirement is that the density of the lighter component differs by at least 10% from the density of the heavier component–the greater the difference in density, the better the percent resolution. Extension of the concept can be applied to systems such as filler or pigment in plastics, hydrous in anhydrous components, oxide in hydroxide, tin in solder, and solid in liquid. It is even possible to measure liquid in liquid mixtures such as oil in emulsion and alcohol in water if vapor pressures are relatively low.

Conclusions

The Ultrapyc 5000 is ideal for measuring density of slurries. The instrument design is such that expansion from the reference chamber to the sample chamber can be utilised to minimise vapor pressure effects. The percentage of solids in a slurry can be calculated if the densities of the individual components are known and measurements give good agreement with known mixture weight percentages.

Find out more about Anton Paar Ultrapyc series

Contact

Anton Paar Product Manager – Surface Area and Pores: Varsha Ramdeen

+27 71 623 7661 / +27 10 443 0975

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation