Setting the seal on material challenges in food applications

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

There are many challenges facing manufacturers of equipment and appliances for use in food applications, not least which materials to select for food-contact components and seals. In the interests of performance, as well as hygiene and health, strict legal and exacting technical requirements apply to those supplying the food plant, restaurant and domestic kitchen markets. In fact, with the number and range of regulations in place, matched by the wide choice of material compounds available, choosing the correct material for each application has proved somewhat difficult, until now. Today, the introduction of a single, universal material that covers many demands in the food sector is simplifying matters for designers and providing reassurance.

Modern food plants and kitchens are filled with technology; all of which requires components and seals made of high-performance materials. Food processing machines, for example, increasingly rely on polymeric components such as tubes, covers and housings, along with highly stressed engineered elements like seals, wipers, guides and pistons. The choice of plastic over metal represents a cost-effective and weight saving strategy in many of the latest systems and appliances, particularly as carefully selected polymers meet the necessary technical requirements in terms of temperature resistance and structural strength. However, choosing the most appropriate material has traditionally been just as challenging, not to mention costly in terms of the related expense and effort.

The introduction by Parker Prädifa of W6101, the food variant of the universal material nobrox®, offers a single and comprehensive alternative to using multiple compounds; both in terms of regulatory compliance and technical performance.

Regulatory requirements

The list of legal provisions in the food industry is extensive. For instance, there are rules governing documentation, the chemical composition of compounds and the way they are processed and handled. In Europe, EC 1935/2004 and EU 10/2011 outline the demands made on materials and objects intended for contact with food and its ingredients. In the US, FDA regulations such as the Food Contact Substance Notification are in place, alongside standards such as NSF 61 (US drinking water approval).

Of course, if a universal material solution is to be widely adopted by the food industry, regulatory compliance must be matched by technical performance. Material attributes and characteristics must include extremely high wear and abrasion resistance, high elastic resilience and wide media resistance. In addition, the material should offer robust and simplified assembly.

Beginning with wear resistance, moving machine elements like seals, wipers and guides are usually required to function in a dry-run environment under elevated tribological loads. This factor, in combination with extended lifecycle requirements, ensures that the deployment of suitably wear-resistant materials is essential.

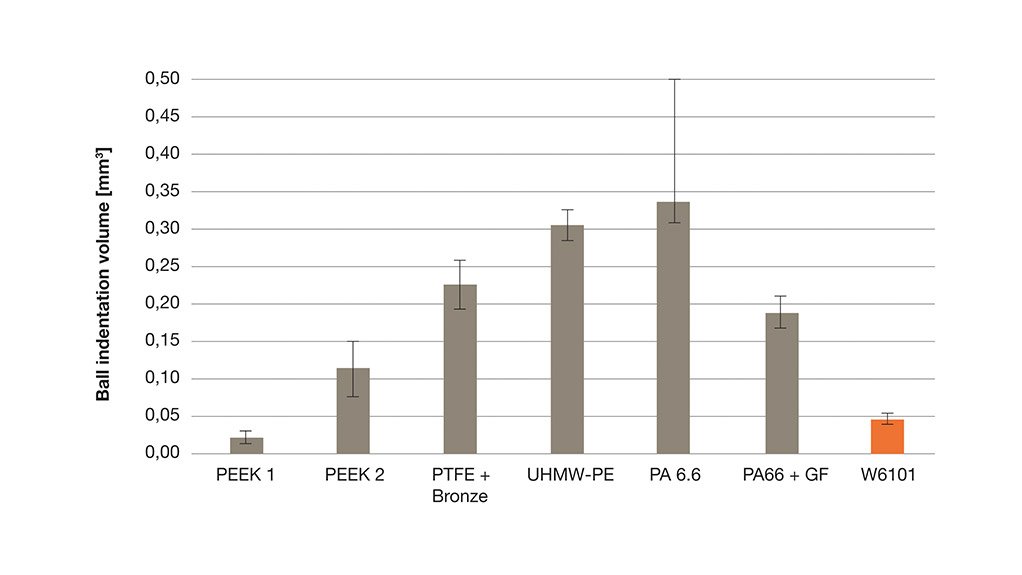

To determine whether a food-grade material will be capable of meeting these demands, appropriate wear- and creep-resistance tests (in accordance with ISO 7148) are needed.

Testing the potential

Such tests stipulate that a rotating ball be pressed against material specimens at a predefined force. Here, the volume of the resulting indentation permits an evaluation to be made of the combined wear and creep tendency. For a universal material to be successful in such a test, it would have to exhibit performance levels similar to that demonstrated by PEEK compounds. Furthermore, the material under test would have to show a significantly lower ball indentation in comparison with PTFE, UHMW-PE and polyamides in order to offer the tribological suitability necessary for components such as seals, engineered elements or guides.

With regard to chemical compatibility and reaction potential, foodstuffs can be generally classified as aqueous media containing a large number of polar and non-polar substances and chemicals. Take milk for example, which is essentially a mix of polar water and non-polar fat. As the Latin phrase ‘similia similibus solvuntur’ states, similar substances will resolve similar substances. Concerning milk, this means that a polar medium like water will resolve a polar polymer such as polyamide or cause it to swell. Similarly, a non-polar medium like olive oil will attack a non-polar elastomer such as EPDM.

With these thoughts in mind, it becomes clear that even the demands required of a polymer in terms of its basic compatibility with milk are anything but minor.

Alongside chemical compatibility, materials must also be assessed and tested to ensure that any reactions with foodstuffs can be excluded, as well as any change in taste. For these reasons, migration tests are deployed to determine what extent ingredients from the material migrate into foodstuffs, and vice versa.

The hygiene factor

Of course, hygiene is a major consideration in all food industry applications. Here, as the number of parts reduces, so do assembly requirements and the cuts and joints of the design, which harbour the greatest risk of contamination and accumulation of food residues and micro-organisms.

The food industry is notorious for its long and costly cleaning cycles. Subsequently, a more effective approach is to counteract the causes and risks through materials expertise and intelligent design, rather than combatting the effects with ever more aggressive cleaning media. In household appliance sector particularly, fewer components translates into ease of use, which becomes an important selling point for the device manufacturer.

In conclusion, a substitution of typical materials found in the food sector, such as PEEK, PA, POM, PTFE, UHMW-PE, TPE-U or various elastomers, makes sense and is feasible in a wide application window. Now, thanks to the universal materials such as Parker’s W6101, this notion can become a reality. Although the material can be classified between thermoplastic materials such as polyamides and PEEK in terms of its mechanical properties, there are crucial advantages compared with polymeric materials used commonly in the food industry. Indeed, W6101 outperforms these materials in tests, complies with all relevant EC/EU and FDA regulations, and simplifies assembly. As a result, the material is suitable for dynamic seals or wipers, as well as many other engineered parts that include pistons, guides or gearbox components.

As such a versatile material, W6101, with its technical properties and potential for component integration and compound variety reduction, offers a new way to solve engineering challenges and reduce costs in the food industry.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation