CSIR simulation assisting in truck flow improvement on the N4 corridor

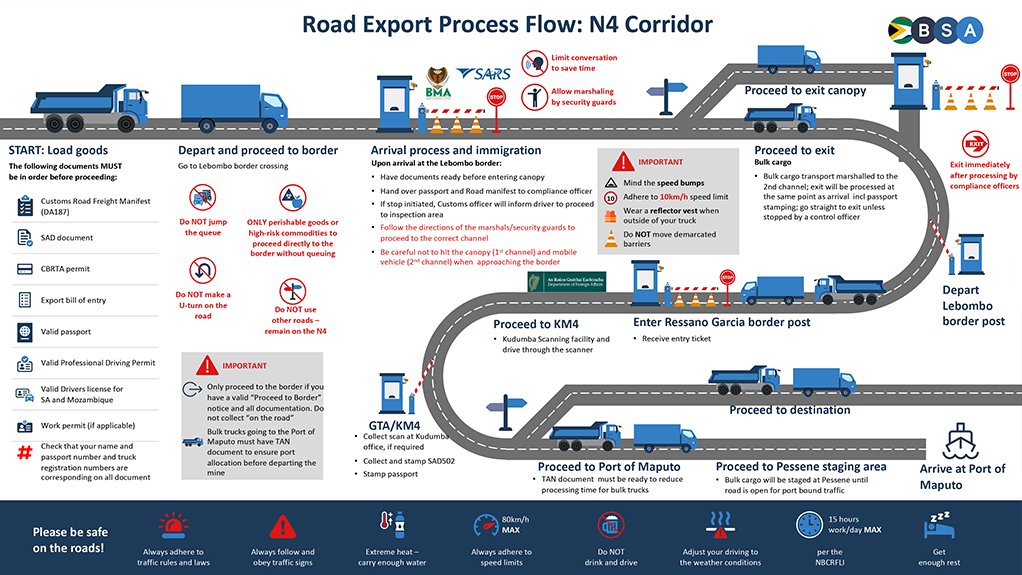

A simulation model developed by a team at the Council for Scientific and Industrial Research (CSIR), in Pretoria, is being used as a tool to improve the flow of trucks on the N4 road corridor.

These trucks, mostly loaded with export minerals, travel from the mines in the North West, Mpumalanga and Limpopo provinces to the Port of Maputo, in Mozambique.

Similar road traffic simulations were originally developed and used to improve coal supply chains to Richards Bay decades ago and were used again in preparation for the 1994 elections and more recently for supply chain optimisation.

In the case of the N4 corridor project, a “What If” analysis is undertaken for various modelling scenarios.

This system highlights impacts down the line and in other areas without affecting real-time operations on the corridor itself. Subsequently, the revised system’s efficiency is monitored on an ongoing basis to see if there are any deviations and, if so, why.

Congestion on South Africa’s major transport corridors is said to remain the key factor affecting road transport.

For instance, the average number of extra-heavy cargo trucks on the N4 daily is about 4 500, with about 1 600 of those carrying loads destined for export.

This illustrates the critical need to cut travelling time and to speed up the border crossing processes, thereby lowering overall logistics expenses, it is emphasised.

“It is gratifying that focused attention has been given to the processing of vehicles through the port of entry, while traffic management on the corridor is benefitting from the improved control of truck queuing,” says corridor specialist and National Logistics Crisis Committee (NLCC) Workstream 2 participant Barbara Mommen.

Members of the NLCC agree that it is important that specific attention be given to prioritising bulk mineral exports, which comprise most transit exports from South Africa through the Port of Maputo, and which are the major contributor to congestion at the Lebombo border post.

South Africa’s mining sector contributed about 6.2% of the country’s GDP in 2023. Improved efficiencies and competitiveness are crucial for the sector’s supply chains as it competes internationally for business, it is noted.

Also, increased efficiencies and improved turnaround times are said to be essential if mining and logistics operations are to ensure sustainable commercial operations going forward.

The NLCC has identified several key actions to improve efficiencies in South Africa’s freight logistics system and to increase total export volumes, making the country more competitive as part of global supply chains.

This must include reducing congestion and improving the efficiency and performance of all the systems involved in moving cargo along the various transport corridors.

Already there are several positive indicators which show the benefits of the NLCC’s work, linked with the CSIR modelling process, it is highlighted.

One of these measurements is the decreasing average length of the queue at the Lebombo border post in Mpumalanga, which decreased from 16 km in October and November 2023 to 7 km in February.

Data obtained from the Logistics Management System, which tracks the real-time movement of a percentage of vehicles on the N4 route, is measured against a corridor performance index. Data from the South African Revenue Services also assists in validating information collected on the corridor.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation