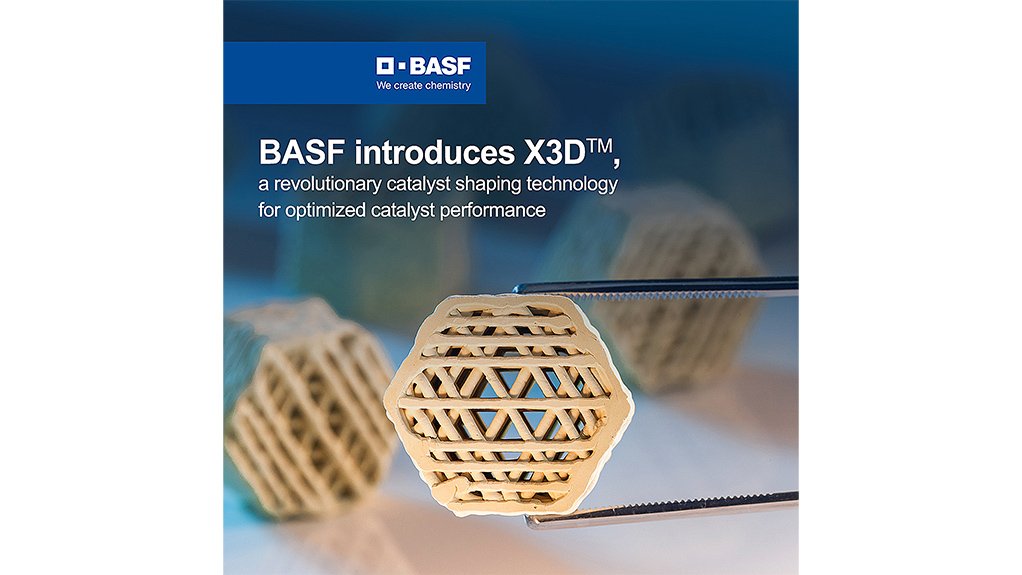

BASF introduces X3DTM, a revolutionary catalyst shaping technology for optimised catalyst performance

- New X3DTM technology to produce catalysts with optimal shape to achieve best performance and efficiency while reducing energy consumption

- Capacity to supply commercial quantities

- Technology can be applied to a wide variety of existing catalytic materials

Global supplier of environmental and process catalysts BASF has introduced its novel X3DTM technology, a new additive manufacturing technology for catalysts based on 3D printing. Catalysts produced with this technology feature an open structure, resulting in a reduction of the pressure drop across the reactor and a high surface area, significantly improving the catalysts’ performance. BASF has capabilities to supply commercial quantities.

The technology offers a greater freedom of catalyst design compared to conventional production technologies. It brings catalysts’ performance to the next level and helps to customise catalysts to customers’ specific conditions and needs by designing infill pattern, fiber diameter and orientation. Customers can benefit from an increased reactor output, higher product quality and lower energy consumption. The novel catalysts are mechanically robust and proven in commercial plant operation externally and for several years in BASF.

BASF can apply the technology to a wide variety of existing catalytic materials, including base or precious metal catalysts as well as carrier materials. BASF’s Sulfuric Acid catalysts O4-111 X3D and O4-115 X3D are the first catalysts produced with the new technology and are used in industrial plants.

“With this technology, we are able to provide catalysts that are tailored to our customers’ needs to help significantly boost their plant performance while reducing energy consumption and increasing sustainability at the customer level”, said BASF Process Catalysts Senior Vice President Detlef Ruff.

“BASF’s technical service team will work with customers to identify the best catalytic technology for their individual projects,” said BASF Global Chemical Market Catalysts Vice President Chris Wai.

BASF’s Catalysts division is the world’s leading supplier of environmental and process catalysts. The group offers exceptional expertise in the development of technologies that protect the air we breathe, produce the fuels that power the world and ensure efficient production of a wide variety of chemicals, plastics and other products, including advanced battery materials.

By leveraging its industry-leading research and development platforms, passion for innovation and deep knowledge of precious and base metals, BASF’s Catalysts division develops unique, proprietary solutions that drive customer success.

Your Direct Southern Africa Contact:

Dr. Saul Colley, Catalysts and Absorbents Expert

Mobile: +27 82 802 8080

Further information on BASF’s Catalysts division is available at www.catalysts.basf.com or watch this video about BASF's Sulfuric Acid Catalysts.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation