Rail – The Future of Africa’s Industrialisation

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

Rail infrastructure upgrades remain a core focus of the ongoing industrialisation of Africa, where the transportation of goods and commodities is often difficult and costly, due to underinvestment in rail infrastructure. China’s October 2015 announcement to pledge US$50-billion towards the industrialisation and development of African infrastructure – together with Transnet’s R300-billion seven-year Market Development Strategy – is a clear indication of the tangible commitment to this lucrative sector.

The MDS is part of Transnet’s ambition to accommodate the fifth-largest railway system in the world by 2019. According to Statistics South Africa, over 734 million tons of freight was moved in South Africa in 2013. It is estimated that over 70% of this freight was moved by road, despite the fact that railways make up a substantial portion of Africa’s transport infrastructure – further highlighting the need for rail upgrades.

Since its announcement in 2012, the MDS has made significant strides and, as a result, South Africa will continue to shift its freight from road to rail, cutting both logistical costs and carbon emissions in the process. According to the MDS overview, rail volumes are projected to increase from approximately 200 million tons to 350 million tons by the end of the programme in 2019.

In March 2014, Transnet announced a R50-billion contract with four manufacturers to build a fleet of 1 064 new locomotives to drive forward the MDS. Power, efficiency, and reliability are key to powering these machines, which are responsible for pulling multiple wagons that carry substantial amounts of precious cargo across vast distances. Any engine failures and associated downtime is too costly and therefore not an option.

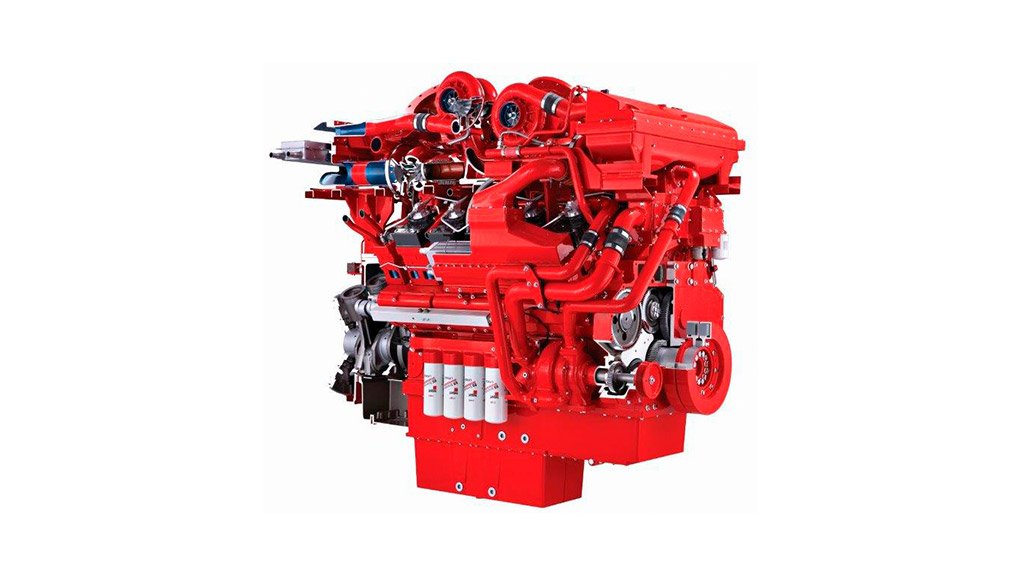

The first Cummins QSK95 engine designed specifically for the rail market began production at the Seymour Engine Plant (SEP) in the USA in September 2015. At 2 983 kW, the QSK95 is the highest-output 16-cylinder high-speed diesel engine available in the market.

Combining Cummins’ latest-generation Modular Common Rail Fuel System (MCRS) technology with quad-turbocharging and integral Selective Catalytic Reduction (SCR) after-treatment, the QSK95 delivers reduced noise, excellent response and ultra-low emissions capability in a smaller footprint than the medium-speed diesel engines traditionally used in locomotives.

Cummins has delivered the first QSK95 engine built to a rail specification to Siemens for installation to its Charger locomotive, a new diesel-electric locomotive designed for the North American passenger rail market. The Charger locomotive was delivered into the market in 2016. Although it is currently being manufactured for passenger operations, the Cummins QSK95 is just as suited to freight applications, in any operating conditions.

“Cummins welcomes the opportunity to partner with customers globally to help them succeed,” says Madelyn Pretorius, Leader, Rail Sales & Business Development. “We are pleased that our ultra-clean diesel engine technology is helping them operate efficiently while significantly reducing emissions and improving the environment.”

Cummins has 70 years of experience, with proven reliability and durability in high speed diesels in rail. The company currently has over 13 000 engines in railway service globally. Locomotive, railcar, track maintenance and auxiliary power applications are all available in the Cummins engine product range in the rail segment, covering a complete power range up to 4400 hp using the QSK95 for both new and repower needs in this sector.

“Cummins boasts extensive distributor coverage in Africa, with engine rebuild and service capability to support our product. We are able to offer best in class solutions to reduce customer total cost of ownership and still meet the harsh conditions of the African continent,” adds Andy Pilkington, Director Africa Rail Business.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation