Majuba silo collapse pushes system ‘over the edge’, summer load-shedding risk high

Eskom executives at Sunday's breifing on the Majuba silo collapse

The central silo at Majuba collapsed at 13:12 on Saturday November 1

Photo by Eskom

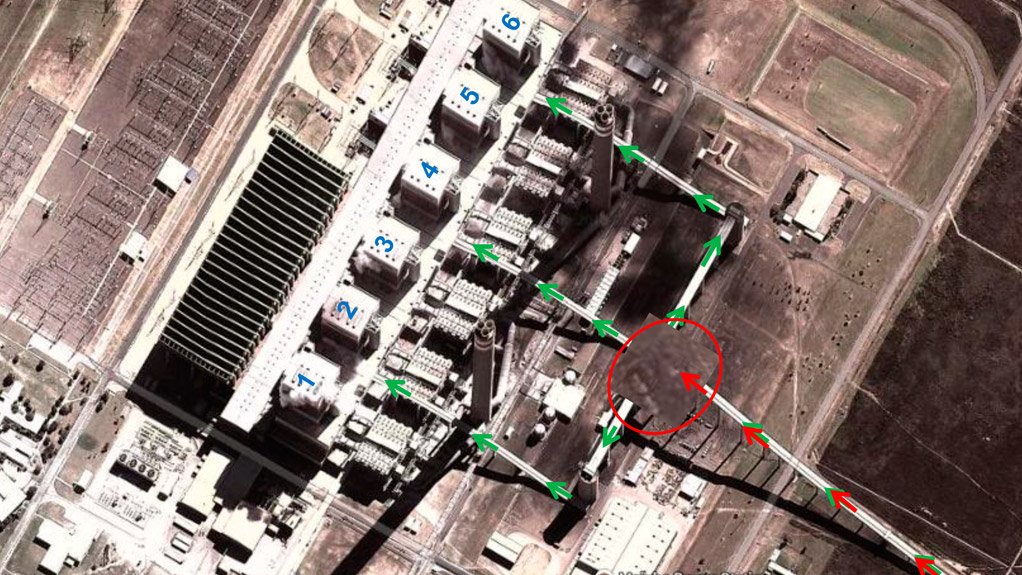

Cellphone camera images of the collapsed silo

Electricity utility Eskom confirmed on Sunday that the risk of load shedding had increased materially for the coming week in light of a catastrophic failure of the 10 000 t central coal storage silo at its Majuba power plant at 13:12 on Saturday November 1.

The State-owned company also indicated that its full summer plan would need to be reviewed and that spates of load shedding were possible until the end of March 2015, owing to the need to persist with a maintenance catch-up programme during the period.

The Majuba station, in Mpumalanga, had been forced to reduce output from over 3 000 MW to around 600 MW, pushing an already constrained power system “over the edge”, and resulting in over 1 000 MW (stage two) of load being shed on Sunday as part of a reserve restoration exercise designed to stabilise supply ahead of the business week.

Nevertheless, there was still a likelihood of ‘stage one’, less than 1 000 MW, of rotational load shedding on Monday between 18:00 and 20:00. That risk would increase by Wednesday once Eskom’s pumped-storage reserves and interruptible loads with the aluminium smelters had been exhausted. As a result, the utility was cautioning that there could be load shedding on Wednesday night and all day on Thursday.

Newly appointed CEO Tshediso Matona – who described his first official media briefing, convened hastily on Sunday afternoon, as a “baptism of fire” – said that short-term measures were being introduced to restore five of Majuba’s six units to partial load – the sixth, which was scheduled for a major overhaul in a few weeks time, would immediately be brought into the maintenance pipeline.

Arrangements had been made, Matona said, for permits to transport mobile coal feeders to site to enable a short-term manual-feed solution. The remedy would require additional front-end loaders to shovel coal at the stockyard onto trucks that would deliver coal to conveyors that feed the units’ coal bunkers. An initial rate of 15 loads an hour was envisaged at a single feeder point, which was likely to be doubled at a later stage.

However, neither of the other two silos on site would be employed until Eskom was satisfied that they were structurally sound, with initial investigations of the central silo, which had been constructed in 1994 and visually inspected in September 2013, showing worrying signs of reinforcing-steel bar corrosion – the silo's design life was meant to be 50 years.

That said, Eskom was currently viewing the collapse as an “isolated incident”, stating that the first sign of structural weakness was only detected by a conveyor maintenance crew less than an hour ahead of the collapse. The crew, which was evacuated, detected coal falling from a crack about 30 m up on the wall of the 40 m silo's concrete structure. The crack was detected at 12:30 on Silo 20 and the collapse, which was recorded by cameras on site, took place at 13:12.

In a parallel intervention, Matona had appointed a recovery team, led by executive Dan Marokane, to restore full operations at Majuba over the medium term. No timeframe was given as to when the 4 110 MW would be returned to steady-state operations.

Group executive for sustainability Steve Lennon indicated that the challenge for the coming period would be “to ensure that there was sufficient generation capacity throughout the day, as we continue with our maintenance plan and focus on reducing unplanned outages.”

Lennon stressed, though, load would be shed should it be necessary to protect the power system from total collapse. He said that Eskom was acutely aware of the economic and social costs of load shedding and would, therefore, only “take as much as we need and as little as possible”.

It would also continue to draw on its expensive diesel-fuelled open cycle gas turbines in the Western Cape, as the economic cost of load shedding was “ten times” that of the cost of producing power at the facilities.

Comments

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation