Industrial distributors adding value and support from design through to MRO

This article has been supplied as a media statement and is not written by Creamer Media. It may be available only for a limited time on this website.

The changing face of industrial distribution

The traditional perception of an industrial distributor as simply a stockist and seller of products is, in modern manufacturing terms, somewhat outdated. Today, pushed by product manufacturers and pulled by end users, distributors must add value in order to provide market differentiation, deliver valuable services, build important customer relationships and secure repeat, ongoing business.

Of course, the term ‘distributor’ means different things to different people. A simple hydraulics dealer, for example, will base its business on making opportunity sales to small MRO-type companies, while a network of wholesale trade dealers will likely support the entire aftermarket needs of specific OEM customers. Moving up the scale, national/catalogue distributors will deploy a generalist sales force to address customers requiring a broad basket of products.

More sophisticated capabilities

Taking the distributor concept a stage further, system integrators can be categorised as engineering organisations that design solutions and build systems based on customer specifications through the application of advanced technology know-how. However, to ensure end users receive guaranteed added value time after time, companies such as Parker require certified distributors to reach levels of expertise and deliver proven performance and customer value over a period of years.

It’s fair to say that occasional users, mobile service stations and light assembly workshops will likely have different requirements of distributors to those of industrial manufacturers, large-scale production companies and multi-plant corporations. Depending on the end user, priorities and emphasis will shift between proximity, speed and professionalism of service, as well as relationship, technical expertise/solutions, peace-of-mind and TCO (total cost of ownership). Moreover, in many instances there are growing ‘e-expectations’, from mobile apps and account management, through to streamlined ordering processes and integrated e-procurement solutions.

Advanced systems integration and support from a distributor

Through newly-introduced initiatives such as Parker’s Hydraulic Technology Centres (HTCs), there are many ways that different distributor networks can add value for end users. For instance, this can be achieved by maintaining local stock for quick delivery in the event of machine breakdown, deploying kitting and Breadman concepts to serve end customers, and perhaps most importantly, providing technical expertise to prescribe the right product.

Value can be extended further, for example, by bringing local assistance to customers in case of urgent troubleshooting, such as hose replacement or cylinder repair, providing local services such as condition monitoring, training end users on fluid power and other technologies or products, and building systems or assembling sub-systems for customers.

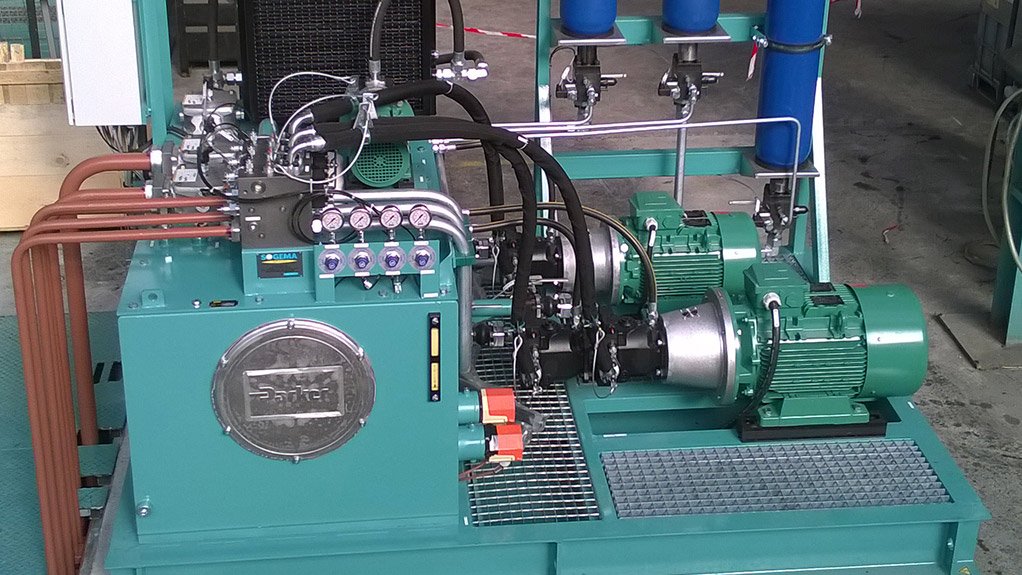

By definition, each HTC is a focused hydraulic engineering house with value-added services to provide the total hydraulic needs of industrial customers. When supporting a complete hydraulic systems approach, many additional Parker technologies and products may become part of the overall solution. These can include electronic controls, electro-mechanical parts, automation, machine intelligence and filtration. Combining these in a correct and optimised way is the skill of the HTC, backed by Parker’s huge expertise and resource pool, to give the end user a high performance, cutting edge and differentiated solution.

For the customer, post-design benefits are as important, if not more so than a neat, integrated solution. For example, increased productivity through enhanced machine performance saves cost and maximises competitiveness in the market place. Similarly, optimised, well designed integrated automation solutions are likely to be more reliable than separate elements linked together in some way. Other aspects that can be optimised are energy efficiency – a well-recognised payback of an integrated solution, as well as precision and security.

Downtime is a big worry in production environments as the costs and implications can quickly spiral. Putting the work in at the design stage with a partner such as an HTC will help reduce the risk of breakdowns and downtime. In addition, if some kind of failure does occur, the local nature, broad technology expertise and experience in the specific system, make the HTC ideal to get a line back up and running in the shortest time possible.

Parker HTCs succinctly refer to the concept of offering multi-technology integrated designs along with test and post-implementation MRO services as a ‘360 degree’ service offer.

Looking to the future, Parker sees its HTCs embracing Industrial Internet of Things (IioT) technology. This will allow HTC engineers to remotely monitor many parameters of a machine’s performance through the use of wireless sensors strategically placed to provide data and even control over the Internet. Such technology can lead to even better response rates and speed of intervention to foresee problems and minimise downtime.

As the extension of an organisation such as Parker, the technical teams at HTCs need to stay up-to-date on the latest products and emerging technologies. This means a continual program of training in products, techniques, systems and services is imperative to maintain the value proposition to end customers.

To follow this growing trend in the distribution sector, and in Parker’s case, to become a Parker HTC, a distributor must be willing to invest in its future. This investment will vary in size depending on where it is today versus the requirements needed to qualify. However, Companies such as Parker view a long-term relationship and that reflects and provides a return on investment for the extensive support and commitment provided.

Distributors need to demonstrate not just hydraulic engineering expertise, but be able to offer total system design, build and troubleshooting and then MRO type services. For a typical customer, this will likely incorporate integrated manifold circuit design and layout, in-depth electronic interfacing and diagnostics expertise, and product conversion, repair and testing capabilities.

From a hydraulics perspective, supplying a single integrated solution includes all related components, including cylinders, valves, accumulators, vane pumps and motors, pumps and piston engines, cartridges, filters, connectors, hoses and couplers. Furthermore, the need for electromechanical components (drives), electronic control systems and pneumatic components will need to be considered where required.

In terms of the skills that a Parker HTC must possess, the attainment of TQM/ISO quality systems, the ability to offer full-time hydraulic systems engineers, and a hydraulics-oriented field sales force and fluid power unit assembly skills are key. Standard onsite facilities should include a CAD station, diagnostics equipment, a hydraulic trainer/test stand and an in-house training room, plus a full complement of services and capabilities, including design, assembly and commissioning.

Summary

The industrial distribution landscape is changing with the types and capabilities of distributors broader than ever before. At the all-encompassing end of the scale are set-ups such as Parker’s HTCs who offer a high degree of capability in hydraulics and inter-related technologies and the ability and know-how to support value-added services that enable them to design and specify integrated system solutions. The nature of these should lead to greater reliability, reduced downtime and an overall solution that is better engineered and more efficient and cost-affective.

Comments

Press Office

Announcements

What's On

Subscribe to improve your user experience...

Option 1 (equivalent of R125 a month):

Receive a weekly copy of Creamer Media's Engineering News & Mining Weekly magazine

(print copy for those in South Africa and e-magazine for those outside of South Africa)

Receive daily email newsletters

Access to full search results

Access archive of magazine back copies

Access to Projects in Progress

Access to ONE Research Report of your choice in PDF format

Option 2 (equivalent of R375 a month):

All benefits from Option 1

PLUS

Access to Creamer Media's Research Channel Africa for ALL Research Reports, in PDF format, on various industrial and mining sectors

including Electricity; Water; Energy Transition; Hydrogen; Roads, Rail and Ports; Coal; Gold; Platinum; Battery Metals; etc.

Already a subscriber?

Forgotten your password?

Receive weekly copy of Creamer Media's Engineering News & Mining Weekly magazine (print copy for those in South Africa and e-magazine for those outside of South Africa)

➕

Recieve daily email newsletters

➕

Access to full search results

➕

Access archive of magazine back copies

➕

Access to Projects in Progress

➕

Access to ONE Research Report of your choice in PDF format

RESEARCH CHANNEL AFRICA

R4500 (equivalent of R375 a month)

SUBSCRIBEAll benefits from Option 1

➕

Access to Creamer Media's Research Channel Africa for ALL Research Reports on various industrial and mining sectors, in PDF format, including on:

Electricity

➕

Water

➕

Energy Transition

➕

Hydrogen

➕

Roads, Rail and Ports

➕

Coal

➕

Gold

➕

Platinum

➕

Battery Metals

➕

etc.

Receive all benefits from Option 1 or Option 2 delivered to numerous people at your company

➕

Multiple User names and Passwords for simultaneous log-ins

➕

Intranet integration access to all in your organisation