In the world of water industry and marine applications, material choice is of extreme importance, as these are challenging environments where constant exposure to weather can really place tough demands on design materials. Aspects such as durability, weight and corrosion resistance all play an important role in such applications.

According to Glen Pringle, Director of Vital Engineering, it is for this reason that the demand for their glass-fibre reinforced products has been steadily growing over the past few years, in a wide range of water-related fields ranging from oil rig platforms, jetties for leisure boating and sailing, aqua plants, fish farming, and dredgers to name a few.

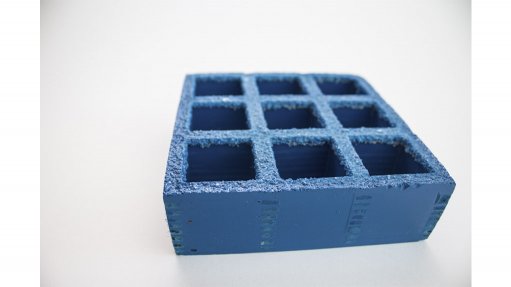

“Our Vitaglass range is a resin-based, glass-fibre reinforced material for hand railings and flooring, which lends itself perfectly to demanding environments – and is especially suited for wet and corrosive conditions,” Pringle explains.

“It is typically used for flooring or barricading, where the material’s corrosion resistance and strength place it in the same league as steel or noble metals – with various price options available,” he points out.

The Vitaglass range is steadily growing in popularity among the leisure boating and sailing communities since – apart from being highly practical and durable – it can be manufactured in a wide range of aesthetically pleasing colours and designs with the option of adding fire retardant and UV inhibitors in the manufacturing process.

“We are very pleased that our products are steadily gaining a solid reputation as an environmentally-responsible and low-maintenance alternative to traditional materials like wood among discerning consumers,” he notes.

On the other end of the water industry spectrum, the Vitaglass range can also be used in industries where there is contact with effluent streams – such as wastewater treatment works and other industrial applications.

For these situations, Vital Engineering’s clients can enjoy the benefits offered by Vitaglass over more expensive materials without compromising on safety or quality, since all the company’s products are manufactured in line with the most stringent international standards.

“The global standards we work according to are also underpinned by our excellent track record as a trusted supplier of non-slip floor gratings and walkways, safety handrails and stair treads for almost 80 years now,” Pringle adds proudly.

“Vitaglass is such a versatile and dynamic product range that we have yet to reach the limit to its applications. Based on the many advantages in terms of price, weight, maintenance requirements and easy on-site installation, it is no wonder that new uses for it are being discovered every day,” he remarks.

“One of the distinguishing factors of the range is that it empowers the designer to think ‘outside the box’, since the manufacturing process allows for great flexibility,” he adds.

“We can tailor everything from the shape of the casting, patterns, material thickness and chemical properties to the clients' needs – thereby giving them increased freedom.”

For example, a flooring surface can vary from solid or patterned top, to mini-mesh with a fine grit top surface – where the small apertures allow for comfortable walking and prevent objects from falling through – to standard aperture meshes for maximum ventilation and quick drying properties.

Furthermore, Vitaglass gratings can either be moulded or pultruded, with pultrusion resulting in a stronger material. A structure’s strength can also be improved by a ribbed design for greater load-bearing properties at a lighter weight. Lastly, the material properties can be altered by adding special chemicals into the resin mix, which bring about specific characteristics in the end product.

“We are able to offer our clients the full spectrum of glass-fibre reinforced products. To this end, we really appreciate it when they engage us from the early design phase of their projects, so that we can work with them to produce a tailored solution which exactly meets their specific requirements,” he says.

“We are really excited about the dynamic, incremental growth we are seeing within applications in the water industry for our Vitaglass range. We are convinced that this will continue as more clients discover the clear advantages it offers,” Pringle concludes.