South Africa faces a looming ventilator shortage as the number of confirmed Covid-19 cases increases, daily.

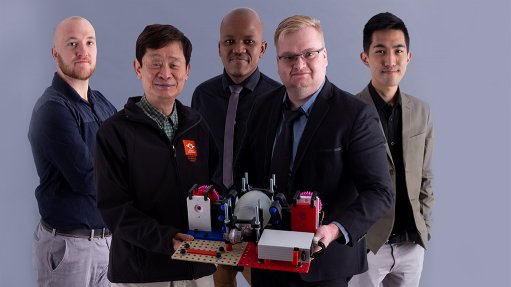

In light of this, a University of Johannesburg (UJ) engineering team designed and developed portable 3D printed mechanical ventilators that have a customisable base plate to treat multiple patients.

The ventilator, named AURA IMPRIMERE, meaning A Breeze of Air Provided by Printing is portable and allows off-grid operations for up to one and a half hours.

Professor Tien-Chien Jen, UJ’s Head of Department of Mechanical Engineering Science and project team leader, says the ventilators are safe to operate. “These unique 3D printable ventilators use a microcontroller to control the operation of the two motors. By adjusting the speed and direction of rotation of the motors, it is possible to obtain a pressure-time profile that is suitable for respiratory assistance of patients.”

AURA IMPRIMERE has a battery system that will ensure normal functioning whilst the demand for electricity exceeds the available supply, adds Prof Jen. “Its components are designed in such a way that it can be easily assembled, on site in cities, rural areas, or remote areas.”

“The microcontroller monitors the pressure inside the Ambu bag by using a pressure sensor. If the pressure sensor picks up irregularities in the pressure, then the motor controller will intervene to correct these issues. It is also important that the mechanical arms of the ventilator operate in unison. Sensors that monitor the position of the ventilator arms are also used to enable the microcontroller to keep the mechanical arms of the ventilator in sync,” explains Prof Jen.

The UJ-led team plans to distribute the active breathing circuit system on an “open source” basis, making the software and designs freely available and can be produced anywhere in the world, provided that the producers own a 3D printer.

AURA IMPRIMERE is based on a reciprocating engine piston and crank design. The motors were extracted from locally bought electric screwdrivers. The ventilator allows for electronic components, such as a control resistor, variable resistor, and a small programmable computer to be used. These electronic components can customize the pulse needed for the patient and can vary the speed of the pulsation. The crank design provides a linear motion for the slider relative to the slider base. Here the “fingers” are integrated that pushes the ambu bag and allow it to deflate. The design is such that the friction between moving parts is minimized.

Professor Jen concluded that the design by which the Ambu bag being placed as the centre component of the design is secured with clamps. “The Ambu bag comes in different sizes, and the invention can be custom changed with ease, on site, according to the patient age, condition, and breathing necessity. This is due to the meshed base plates that allows the clamps, mechanism, electrical housing, etc. to be reoriented and placed as the consumer pleases. Inspired by “LEGO” type designs.”