The Faculty of Engineering and the Built Environment at the University of Johannesburg (UJ) is coordinating efforts to further develop open-source ventilators in response to initial reports that between 40% and 70% of South Africans could become infected with Covid-19, depending on the national response to the crisis.

“The goal is not to directly produce ventilators, but rather to create an open-source design that can be leveraged by the community to support local healthcare facilities,” explains UJ’s Dr Deon Sabatta.

This is in addition to providing repair and maintenance support to bring out-of-warranty equipment into service and making rapid prototyping facilities available to enable personal protective equipment manufacturing.

A presentation made to Parliament's Portfolio Committee on Health by Department of Health acting director-general Anban Pillay in early April states that South Africa has less than half the number of ventilators needed to deal with peak infection.

Public and private hospitals currently have 3 216 of the 7 000 ventilators needed by the country.

UJ says it is clear from the expected number of infections, that this will not suffice.

Subsequently, a multidisciplinary team of engineers and healthcare practitioners at the university has taken a three-pronged approach towards supporting critical care technology development in response to the Covid-19 crisis, which is expected to peak in South Africa between July and September this year.

The team, led by UJ’s Sabatta and Dr Samson Masebinu, has identified several simple, safe and scalable open-source designs that could meet the strict specifications for use with patients if further developed and tested.

“The initial open-source designs were obtained from numerous contributors. During the early stages of the project, we identified as many as ten such sources from which to work from. Our current prototype largely resembles that of the MIT e-Vent project,” explains Sabatta.

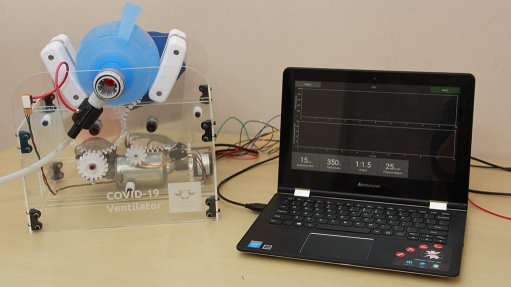

By building on open-source designs, the team has produced a minimal viable product with elements that can be manufactured using three-dimensional printing and laser-cutting techniques.

UJ has some of these devices, but the hope is that ordinary South Africans with access to 3D printers and laser cutters will use these designs to play a pivotal role in assisting with the wide-spread manufacturing.

These designs will support the development of the critical control systems that protect a patient supported by a ventilator against ailments, such as ventilator induced lung injury, that can occur from its improper use.

“Ventilators are complex medical devices and more intricate than simply squeezing a bag. Our product includes devices such as, pressure sensors, flow sensors, and numerous control algorithms,” explains Sabatta.

He adds that the product can, therefore, be set up to perform more advanced ventilation tasks such as pressure support ventilation or synchronous intermittent mandatory ventilation.

“This is a step up in ventilation support,” states Sabatta, highlighting that it can assist patients further when they tire from being on continuous positive airway pressure systems for extended periods.

The UJ Process Energy and Environmental Technology Station (UJ-PEETS) supports efforts to identify decommissioned ventilators at public and private hospitals and to bring out-of-service equipment back online, focusing its efforts on electronic waste reduction in a circular economy to support the medical engineering maintenance programmes at hospitals.

“Our repair and maintenance undertaking will create employment opportunities, as there is a large amlount of equipment that can be repaired and calibrated for reuse locally, as well as beyond South Africa’s borders. The need for these devices is even bigger outside of South Africa. Our efforts can also support neighbouring countries,” says Masebinu.

He adds that there is no sector more critical at this moment than healthcare and the team is, therefore, proud to play a role in helping to produce and revamp these “critical life-saving devices”.

The Covid-19 crisis has highlighted the skills shortage in facility and technical equipment maintenance at healthcare facilities not only in South Africa but in Africa, stresses UJ.

The UJ-PEETS team is gearing up to support and upskill small and medium-sized enterprises in the clinical technical services sector to deliver on the 500% to 1 000% growth in ventilator production needed globally to prevent unnecessary deaths owing to the shortage of these devices.

No ventilators have been produced commercially thus far, states Sabatta.

The team at UJ invites industry partners, researchers and practitioners in the clinical technical services sector to join forces to fast-track research and prototype development, and support critical maintenance activities to ensure that the project can be scaled and replicated on the continent.