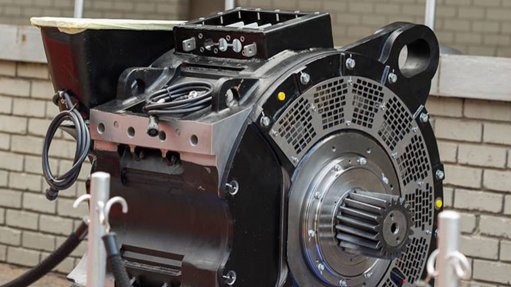

PRODUCT SUPPLY A drive for electric freight locomotive, tested and ready for dispatch

Tier 2 subcontracting manufacturer to original-equipment manufacturers (OEMs) IEC Holden, which supplies electric motors and generators to the railway, power generation, oil and gas, and mining industries, is currently directly contracted to OEMs that supply the Transnet Freight Rail rail expansion project and to Bombela Maintenance Company, which is responsible for maintaining the Gautrain fleet, says IEC Holden GM Ralph Robinson.

“IEC Holden also works closely with large suppliers in the casting, machining and fabrication industries in which we have invested substantially over the past two years to develop the capability to supply parts manufactured to OEM-quality requirements,” he outlines.

To date, IEC Holden has delivered 190 drives, which consist of traction motors and gearboxes, out of an order of 1 400 drives for the OEMs. End-client delays have resulted in a considerably slower delivery rate than originally expected, although the company is equipped to manufacture more than 40 drives a month to contract completion.

IEC Holden manufactures railway traction motors and associated components, including gearboxes. Current production includes fully tested power units comprising a high-power alternating current traction motor and gearbox. Traction motor and gearbox maintenance is also performed at its Isando facility. IEC Holden also performs the light overhaul of the traction motors and gearboxes for the Gautrain fleet.

“Programme delays have put substantial stress on the entire freight rail equipment supply chain, as well as supplier and personnel skills development. Manufacturing for OEMs is a tier above what the local rail manufacturing industry was previously skilled for and, therefore, the effect of this requires constant input to ensure quality at supplier and in-house manufacturing levels,” explains Robinson.

Skills Emphasis

To assist in maintaining the levels of constant input, IEC Holden provides in-house training for all its employees on processes and quality management systems.

“Training is provided for all operators and production and office staff to ensure that they have the appropriate skills and knowledge to execute at the required standards to supply OEM-quality products,” he says.

Robinson adds that training and development activity has a multiplier effect, resulting in increased competence and personal career advancement for employees and, ultimately, those benefiting from job creation in the supplier sector of the broader industry.

IEC Holden has equipped more than 120 staff members with competitive skills to operate and execute their respective duties to OEM-quality standards through its in-house training programmes.

However, Robertson says skills development requirements for a Tier 2 OEM subcontracting supplier, such as IEC Holden, are contract and customer specific.

“The requirements vary greatly, depending on the agreement between the OEMs and the end customer, whether government or the private sector.”

IEC Holden is the largest subcontract manufacturer of traction motors in North America, and has branches in Canada, Mexico, the US and South Africa.

“IEC Holden has also invested heavily in supplier development. To date, IEC Holden has invested more than R1.83-million in in-house and external training and development,” concludes Robinson.