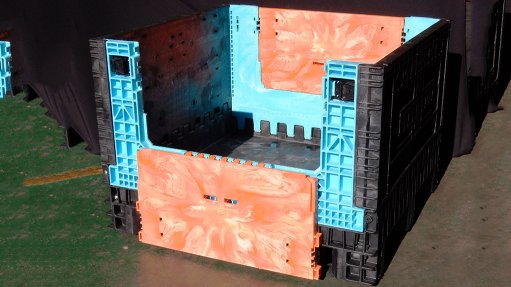

HOLDING IT TOGETHER Collapsible bins were produced to hold automotive parts

Rotational and low pressure injection moulding specialists Kaymac Structural Foam (KSF) completed a contract with a leading German automobile manufacturer last month, where it supplied reusable collapsible bins for components of a new vehicle model being manufactured in South Africa for world export.

The project, which entailed five different manufacturing phases, was completed between April last year and last month.

Almost 4 300 bins, with ten variations, were manufactured, excluding an additional 527 bins made for other vehicle parts for the manufacturer.

The project, initially commissioned in December 2016, entailed the full design and manufacture of the reusable bins to the manufacturer’s specifications. “Our German client had very high expectations of us, and we are proud to say that we supplied the first phase ahead of schedule,” says KSF MD Alvin Pillay.

KSF was given specifications for the bins by the German automobile manufacturer’s North American, branch, and had to make up the bins as close to those requirements as possible, notes Pillay. All of the bins were used for different aspects and parts of the vehicles build.

Pillay says KSF is the only company in Africa that uses structural foam moulding technology, as opposed to the industry standard of high- pressure injection moulding, at its manufacturing facility in Pietermaritzburg. The structural foam moulding process is more robust than traditional injection moulding processes, owing to the strength and durability of the end-product, he outlines.

Further, KSF has also supplied plastic fuel tanks, and also designs and manufactures utility boxes, air intake pipes, wheel arch fenders and seat skids for the automotive sector. They also specialise in the manufacture of “twin walled” polyurethane filled products.

Over the years, its capabilities have also secured the company manufacturing contracts with automotive companies Ford, Nissan, General Motors, Daimler Chrysler and machine industry company Bell Equipment.

The company also has products suitable for use in materials handling, where automotive parts might require crates or pallets specially designed to suit a particular component.

KSF has also been commissioned to design, develop and supply a range of fuel tanks for the military vehicles of the South African National Defence Force.