Smart software solutions revolutionise pneumatics

Quickly activated motion applications (apps) are said to be revolutionising pneumatics by increasing flexibility and energy efficiency, and accelerating production processes.

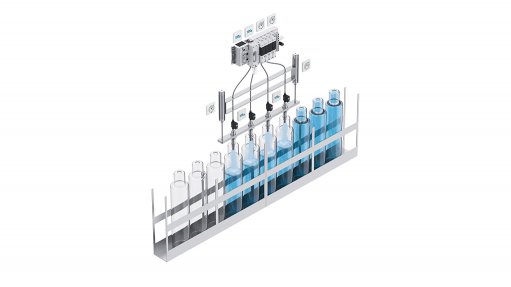

The Festo Motion Terminal VTEM combines digitalisation and pneumatics and aims to make filling containers, such as bottles, with nitrogen or other gases more profitable and economical.

Motion apps control one piezo valve for almost all pneumatic tasks with the use of a single piece of hardware, namely the Festo Motion Terminal. The various functions are controlled using motion apps, with new motion apps being developed to make the Festo Motion Terminal even more flexible. Digitised pneumatics are designed to intelligently connect the mechanical system, electronics and software - ensuring better overall equipment effectiveness with lower energy consumption.

For applications where containers for products are rinsed and filled with gases like nitrogen, the Motion app flow control function allows users to control compressed air and gas flow rates at up to 600 l/min digitally and simultaneously on up to eight independent channels. For precise dosing, the integrated sensors can be combined with external flow sensors, helping to save energy and costly gases.

Controlling the flow in litres per minute using the app allows the gas to be precisely dosed. The more precisely the filling quantity is defined, the more accurate the filling will be since the percentage deviation from the target quantity can be optimally detected. This flexible, digitised nitrogen control is also designed to be tamper-proof.

The app selectable pressure level function is designed to move the filling nozzles to the bottles quickly and accurately, and the flexible parameterisation shortens the cycle times. After filling, the filling nozzles are retracted with reduced pressure to save energy.

The Festo Motion Terminal enables machine developers to create a basic machine type and then select the relevant Motion app functions and features according to specific requirements. The ability to copy and transfer parameter sets facilitates planning and saves time. Using software to assign functions has the added benefit of preventing tampering and improving security, as the functions being executed by the valves are not visible from the outside.

The app’s leakage diagnostics function helps to simplify maintenance by automatically monitoring leaks, helping to detect malfunctioning, pinpointed to a specific actuator, using diagnostic cycles and defined threshold values which are recognised as the basis for predictive maintenance.