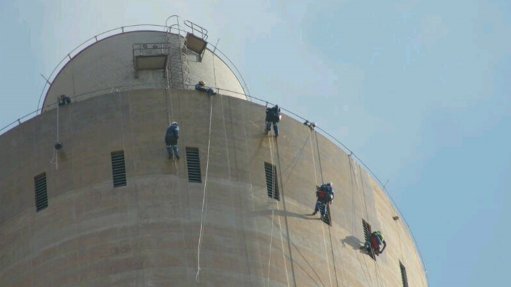

SAFETY AT HEIGHT Rope access technicians are able to carry out numerous tasks relating to inspection, protective coating, maintenance and surveying

Rope access specialist company Skyriders was commissioned in early-2015 by a large, listed, multidisciplinary construction and engineering group to establish, inspect and maintain access systems at a petrochemicals plant for a 14-month period.

Skyriders marketing manager Mike Zinn notes that an eight-man team is responsible for the establishment, inspection and maintenance of the access systems, while a four-man team will provide standby rescue for all personnel.

He adds that Skyriders has been involved in similar projects at power stations nationwide – and experience that has helped the teams overcome the challenges they now face with confidence.

“The men are working in hazardous conditions accompanied by high winds and heavy rain from time to time. Given their past experiences, they are working flexible shifts to avoid any weather disruptions,” says Zinn.

He points out that rope access is a safer and more cost-effective alternative to the more traditional means of access in a number of applications, especially on tall structures at industrial sites, including smoke stacks, cooling towers and boilers.

“Rope access applies practical rope work to enable workers to access difficult-to-reach locations, without the use of costly and time-consuming other means,” says Zinn.

Suspended in their secure position, he states that rope access technicians are able to carry out numerous tasks relating to inspection, protective coating, maintenance and surveying.

When it comes to safety, Zinn indicates that the four-man Skyriders team is responsible for numerous rescue tasks in any application over 2 m above ground.

“Large construction projects, such as [State-owned power utility Eskom’s] Kusile and Medupi power stations, for example, have hundreds of workers operating high above ground on tall structures, such as the cooling towers, boilers and inclined conveyors, which they gain access to through numerous means including cranes, cherry pickers, lifts and scaffolding,” he says.

As a result, there is always the inherent risk of a fall, entrapment, or mechanical breakdown and the highly skilled and experienced Skyriders teams of rope access technicians are on call to rescue workers in the quickest, safest and least-distressing manner possible, Zinn explains.

A rope access technician with Level 3 certification – the highest level of rope access training – forms part of the Skyriders rescue team. Obtaining a Level 3 certification is a rigorous process that requires a minimum of 1 000 working hours to be logged at Level 2 before qualifying for training. This ensures that, in the event of an at-height emergency, the safety of all on-site workers is in “more than capable hands”.

Owing to the large-scale nature of the project, Zinn reveals that Skyriders is committed to providing the safest and most cost-effective method of accessing the work site, in the most nonintrusive manner for workers. “The project is going well and we look forward to undertaking similar jobs in the future,” he concludes.