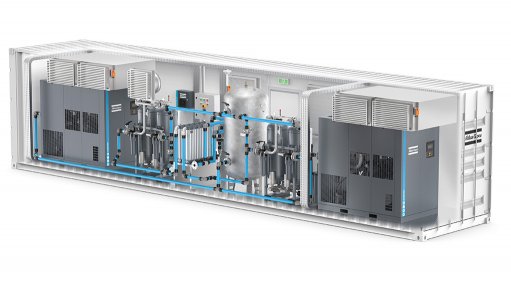

The AIRCUBE compressor room from AtlasCopco

A new way of delivering compressed air has been made available, with the development of a containerised system that houses a complete compressor room in a standard 20-foot or 40-foot shipping container.

Atlas Copco’s AIRCUBE helps to eliminate the need for a compressor room, allowing a containerised compressor system to be placed near pneumatic processes that require compressed air, eliminating the need for building permits and construction costs.

The plug-and-play containerised compressed air system is ready to operate as soon as it arrives on site, allowing for instant full production. The modular system offers a flexible solution and can be customised according to customer specifications and budget. “Customers have the freedom to create their own unique AIRCUBE, conveniently choosing from a range of Atlas Copco products and options to meet their individual compressed air requirements,” explains Atlas Copco Compressor Technique business line manager: Industrial Air division Zandra van der Westhuizen.

“And they can do this in three easy steps. First the customer can select one or two air compressors from Atlas Copco’s industry-leading GA 11+ to GA 90 fixed-speed or energy-efficient GA 7 VSD+ to GA 110 VSD+ variable speed drive machines to form the heart of the air system. Then the customer is able to mix and match Atlas Copco’s CE-certified compressed air treatment equipment including dryers, air receivers and filters. The third step involves choosing from a list of options to customise the AIRCUBE to the customer’s exact needs.”

The company assembles all the required products inside the durable, weatherproof ISO container, which includes a built-in lighting system as well as exhaust air ducts and ventilation fans. As all products and components are from a single source, they are fully compatible.

The containerised compressor room is designed to operate reliably in extremely harsh environments, and to withstand ambient temperatures ranging from -40 °C to 45 °C, and up to -50 °C to 50 °C on demand. The air network inside the container is connected to Atlas Copco’s patented AIRnet system. Manufactured from non-corrosive aluminium pipes, the connections are designed to be leak-proof and to prevent flow and energy losses. Easy access to the container from the inside and the outside allows for ease of operation and maintenance.