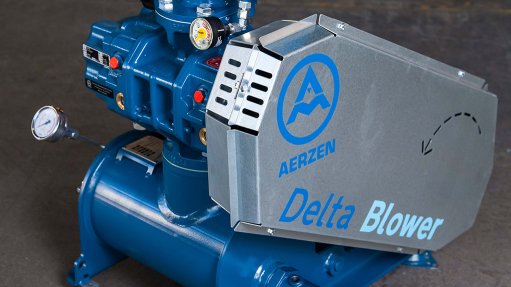

ROBUST CONTRIBUTION The product offering for the KwaZulu-Natal region will include the Aerzen Delta Blower Generation 5 roots type blower for the sugar production industry

Gas conveying and compression company Aerzen Airgas Blowers & Compressors is opening a new branch north of Durban, in KwaZulu-Natal in June.

KwaZulu-Natal Airgas branch manager Earl Houston tells Engineering News that the branch will be operational from June 1, noting that the facility will be a replica of the Johannesburg facility, comprising a workshop for repairs, services, new products and spares.

Although the company generally focuses on South Africa and sub-Saharan Africa as key markets, KwaZulu-Natal is receiving increased market focus, he notes.

“There is a need for an Aerzen Airgas Compressors branch in KwaZulu-Natal. . . The location of the new branch will enable us to serve our customers quicker and better with regard to new product sales and after-sales service,” Houston says.

Aerzen Airgas Compressors supplies roots blowers, rotary screw compressors and rotary piston gas meters for air and process gases to the cement, milling, sugar, water and wastewater, as well as the food and beverage industries.

The product offering for the KwaZulu-Natal region will include the Aerzen Delta Blower Generation 5 roots blower for the sugar production industry, as it contributes to “lower operational expenses because they are efficient, robust and offer low life-cycle costs”, Engineering News reported in March.

The company offers a 24/7 field service, repairs, overhauls and maintenance contracts for the entire range of Aerzener Maschinenfabrik roots blowers and screw compressors. Other services include vibration analysis, whereby technicians capture vibration readings that are used to undertake condition monitoring to predict any possible failures of rotating elements such as bearings – saving customers substantial amounts of money by picking up potential issues before they materialise.

The branch will, therefore, also assist customers in reducing their transportation costs, as customers will not need to send their equipment to Johannesburg for servicing or overhauls, he adds.

Depending on the size of the machine or the equipment, transportation cost savings could amount to about R9 000 every time equipment is transported, while the time and costs of sending a technician from the Johannesburg facility to various areas in KwaZulu-Natal are not only reduced but can also be eliminated, as the KwaZulu-Natal branch will have a technician available to save the customer downtime costs, he notes.

Houston reiterates the necessity of comprehensive after-sales and technical services, as these are key in maintaining the operations of a plant. “A blower or compressor failure can result in an entire plant shutdown.”

The KwaZulu-Natal branch will also aim to stimulate and increase local employment opportunities, Houston emphasises.

Originally from KwaZulu-Natal, Houston says he is happy to be back and is looking forward to building the Aerzen Airgas brand name in the province and assisting all existing and new customers with any requirements they might have.

Aerzen Airgas Blowers & Compressors will have its official opening on Monday, June 8, at its premises in the Time Business Park.