Western Cape asphalt producer, More Asphalt has almost doubled production capacity at its Tygerberg Valley site outside Cape Town with a custom-built continuous mix asphalt plant from Comar.

Starting production in October 2018, the facility impressed its owners by exceeding its operating expectations and producing 100,000 tonnes in its first seven months. According to Owen Peringuey, executive director at More Asphalt, the manufacturing of the plant went very smoothly, in line with the set out plan and within the required timelines.

“It was a pleasure working with a company as professional as Comar,” says Peringuey. “They were able to design, manufacture and commission what we needed, and more.”

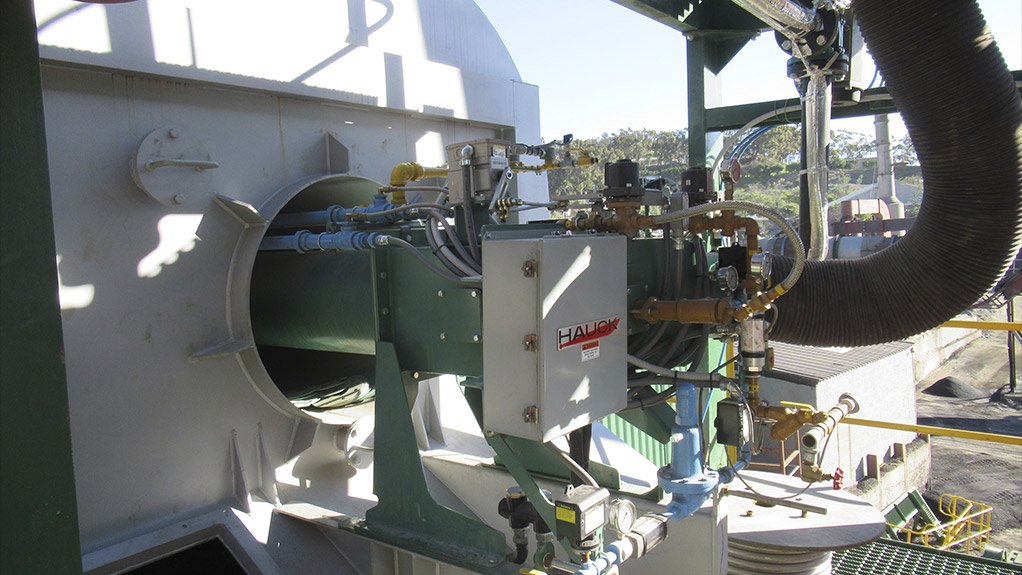

Comar’s team of experienced design engineers, using modern software tools, designed the 140 tonne-per-hour plant to suit the customer’s constrained site footprint. Space savings were achieved through the design and installation of a single combination drying and mixing drum in a counterflow configuration, incorporating a long-nose burner.

“Our years of experience in designing, building and operating these plants allows Comar to customise each plant to our individual customer’s particular specifications,” says Comar director Ken Basson. “As a 100% local company, we also understand the demands of local conditions, and build plants that maximise uptime and productivity.”

The new plant includes six cold feed bins for sand and aggregate and two recycled asphalt pavement (RAP) bins for fine and coarse fragment sizes. A baghouse for catching dust particulate emissions, as well as a state-of-the-art motor control centre in a 12 metre shipping container, are also key elements of the new plant.

“The facility uses a higher quality fuel than normal, providing better combustion and less sulphur burn-off,” says De Wet Dreyer, Comar operations manager. “Among the benefits of this fuel choice is longer bag life and reduced maintenance costs for the overall operation.”

As a result, the plant complies comfortably with new emission standards on dust particulate levels, which require that emissions do not exceed 50 mg/Nm3. A recent inspection of the plant confirmed it was dealing well with the high production volumes, showing little wear on the lifters and also minimal wear in the bags, which were operating highly efficiently.

The design provides for additional loadout flexibility should the customer require it. This allows a fourth product to be discharged directly onto trucks, while the three silos are filled. The scope of work for the More Asphalt contract included disassembling and removing the company’s old plant before installation of the new plant could begin.