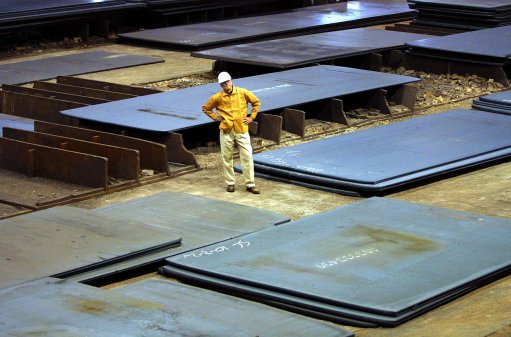

STEEL WORK The DRA had a tight timeline and resolved to construct the bridge using only steel to speed up the construction time

Photo by: Bloomberg

Johannesburg-based mining, infrastructure and mineral processing plant design and construction company DRA has constructed a steel footbridge that links the two sections of its campus, intersected by Leeuwkop road, in Sunninghill, Johannesburg.

The company also entered the bridge in this year’s Southern African Institute of Steel Construction (Saisc) Steel Awards for excellence in the use of structural steel, to be held on September 18 in Johannesburg, Durban and Cape Town concurrently.

The main DRA office park, which is home to more than 1 000 staff members, is located on the west corner of Leeuwkop and Witkoppen roads. DRA last year bought the adjacent building on the east side of Leeuwkop, which now houses its infrastructure division.

“We quickly realised the safety risks involved with staff frequently crossing the busy street and took a decision to construct a footbridge linking the two properties. By mid-2013, all approvals were in place to begin designing the bridge. It was completed last month.

“Because we had a tight timeline, it was resolved to construct the bridge using only steel to speed up the construction time, explains DRA group CEO Paul Thomson.

Engineering consultant Walker Achier Holtzhausen designed the 27.6 m bridge and it has been equipped with composite fibre grate flooring, which is both lightweight and easy to fabricate, while a watertight roof and cable trays do not hinder pedestrians across the entire DRA campus.

The support columns and the steel stair structures were engineered by DRA’s infrastructure division, complete with panels underneath the stairs and space for an elevator to be installed in the future, allowing ease of access for people with disabilities.

The span of the bridge and the access staircases were each fabricated and assembled offsite and arrived bolted together as fully assembled structures. The actual erection of the superstructure of the bridge onto the support columns took less than 30 minutes, and little work was carried out above the roadway, resulting in a safer build with minimal road closure time.

“While functional in terms of safety, the bridge is also visually appealing and stands as a landmark of the DRA head office. We value our people; their safety is our primary concern and a core value of our company. The bridge represents not only our commitment to safety but also our passion for developing creative engineering solutions that are customised to the exact needs of a project,” concludes Thomson.