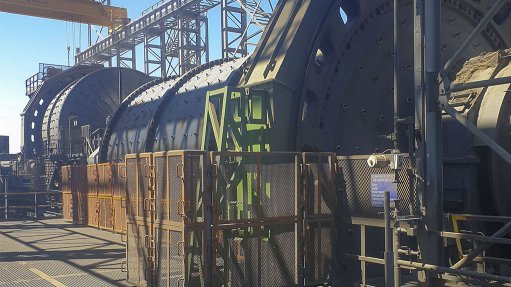

Multotec is developing and applying new liner designs for large-scale mills

The greater use of larger semi-autogenous grinding (SAG) mills to improve productivity in the mining industry is widely recognised and the move has necessitated the development of new liner designs to improve mill efficiency and liner wear life.

The traditional use of steel liners in large SAG mills may present a number of challenges, as the rigidity of steel makes it less than optimal for absorbing the energy of rock material inside the mill and the inexact fitting of steel liners on the mill’s curved surface may lead to bending stress inside the liner.

Multotec highlights that it is meeting these challenges with the development and application of its innovative liner designs to optimise performance and wear life.

“Our strong analysis capabilities in the design process – including discrete element analysis (DEM) and finite element analysis – allow us to continuously evolve the application of our composite liners,” says Multotec global sales and business development manager Sam Hearn.

The company uses DEM software to simulate the interaction between the mill charge and the liners, and to evaluate liner profile over the life of the liner.

“The DEM analysis considers a range of variables such as the ore’s bond work index, its specific gravity, the size of the grinding media, the mill speed and the slurry density,” he says. “Sophisticated simulation capability allows us to accurately model the performance and wear of our mill liners. This includes predicting the liners’ wear life, to avoid unscheduled downtime and to extend the time between replacements,” adds Hearn.

Emphasising that no two mill liner applications are identical, Hearn says that this simulation can guide very specific refinements in the liner design for each customer and stresses that a detailed understanding of the operating conditions is vital to ensure that the final solution delivers optimal results.

“This is where our composite liners come into their own,” he says. “These innovative liners combine the impact resistance of Hardox 500 steel inserts and the absorption capacity of our specially formulated wear-resistant rubber compound. Through the simulation, the structural integrity of the liners can be verified, while the geometric layout of the liners can be optimised.”

The composite liners are locally manufactured at Multotec’s facility in Spartan, Gauteng, and the company emphasises that its advanced processes include its unique submerged cutting technique to preserve the surface hardness of the liners.

Following the design and manufacturing process, Multotec conducts field trials to compare the relative performance of composite liners and steel liners.