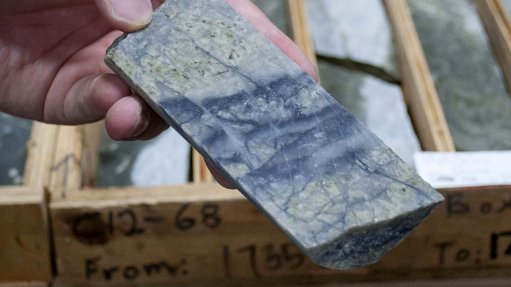

TSX-V-listed American CuMoCo has unveiled its fifth report in 12 years for its copper/molybdenum/silver/rhenium deposit, revalidating the size, scope and potential economics of the project, in Idaho, US.

The updated preliminary economic assessment (PEA) was conducted by SRK Consulting (Canada), Sacré-Davey Engineering and Giroux Consulting.

"The CuMo project is the largest molybdenum, silver and rhenium deposit in the United States and one of the world's leading mining projects in terms of its size, cost, and potential economics," says CuMoCo president and CEO Shaun Dykes.

The key outcomes of the PEA are that the project has an after-tax net present value (NPV), at an 8% discount, of $356-million, and at a 5% discount, of $1.7-billion. The internal rate of return (IRR) is 9%, with an eight-year payback period.

The mine will require initial capital expenditure of $3.07-billion.

Over its 30-year life-of-mine (LoM), CuMoCo will produce 1.29-billion pounds of molybdenum, 2.53-billion pounds of copper, 107 239 oz of silver and 88 361 kg of rhenium, as well as 3 371 t of sulphuric acid.

Cash costs are estimated at 4.67/lb of molybdenum, net of byproducts.

"The results are extremely encouraging, especially indicating a potential total after-tax, prior to capital removal, undiscounted cash flow of $11-billion over a period of 30 years,” says Dykes.

In the 2018 report, the after-tax cash flow was $18.19-billion and the NPV, at a 5% discount, was $5.6-billion. In the latest report, the discount rate increased to 8%, which gives it a value of $356-million.

The IRR in the 2018 report was higher than the current IRR at 25%.

The new LoM is a substantial reduction from the previously contemplated 82 years. The previous economics were calculated over a 40-year period, while the current economics are calculated over 30 years.

CuMoCo explains that the main reasons for the changes are the use of coarse mineral sorting intervals instead of the finer intervals, which had a significant reducing effect on the mill feed grades used in the economics. The switch from fine to coarse sorting resulted in a decrease of about 31% in grades and thus recoverable metals.

The updated PEA, Dykes says, affirms projections and compels completion of the remaining environmental permitting aspects, prefeasibility analysis, and feasibility initiatives to further advance the project.