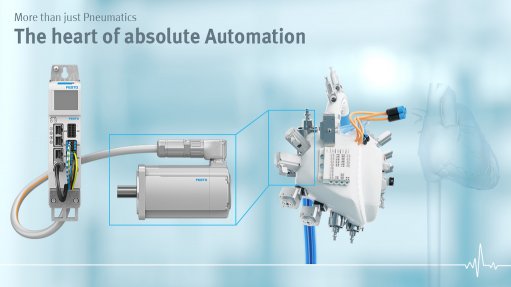

The Festo servo drive CMMT-AS/ST and servo motor EMMT-AS offer an integrated solution

A new complete drive system, consisting of servo drive and servo motor, aims to ensure seamless connectivity in hardware and software, in order to bolster the optimal functioning of machines.

The servo drive CMMT-AS/ST and servo motor EMMT-AS from Festo are connected by means of a one-cable solution and can be put into operation quickly and easily using the Festo Automation Suite programming software. The extra low voltage servo drive can also be used in applications that require low voltages of 24 V and 48 V as well as efficient moving and positioning.

The benefits of the servo drive CMMT-AS/ST and servo motors EMMT-AS include:

- Maximum connectivity of hardware and software

- Greater efficiency and precise positioning

- Complete integration into other third-party control concepts by means of Ethernet-IP, Profinet or Ethercat as their respective protocols, or directly on the motion control system CPX-E from Festo.

- A modular and optimised package design of the CPX-E motion controller and programmable logic controller (PLC) helps ensure low space requirements in the control cabinet.

The compact servo drive CMMT-AS is an integral component of the Festo automation platform and is designed for dynamic motion, point-to-point and interpolating in demanding applications such as packaging machines, assembly and handling technology, or the electronics industry. The direct fieldbus integration to controller manufacturers is said to enable the direct integration of the CMMT-AS into all application programs simply and efficiently.

The ultra-compact low-voltage controller CMMT-ST is said to offer excellent economic efficiency and maximum space efficiency. Positioning tasks or movements with low continuous power requirements of up to 300 W can be solved with the controller and its small dimensions enable optimum use of the installation space in the control cabinet. When operating the CMMT-ST on the existing 24 V DC network and with a maximum continuous output of 150 W, it is possible to do away with the extra power supply unit.

The EMMT-AS is an AC synchronous servo motor for demanding and dynamic applications. Its space-saving single-cable solution aims to reduce installation effort and time, improve the system’s clarity and simplify maintenance. It is characterised by a low detent torque, which helps ensure controllability and path accuracy during positioning tasks, whether linear or rotary. The integrated electronic nameplate stores all relevant motor data and is read out directly by the CMMT-AS to make commissioning easier, safer and faster.

Both the servo drive CMMT-AS and the low voltage servo drive CMMT-ST are programmed and commissioned on the same platform, namely the Festo Automation Suite, which helps to further simplify software requirements.