Supporting companies transitioning to PPE manufacturing.

In what is an unprecedented global emergency where COVID-19 inexorably continues to spread, companies around the world need to band together, think creatively, and act fast to protect all people, but especially our healthcare workers, where the shortage of masks and other personal protective equipment needed to keep them safe is a global concern.

Based on its successful initiative in China, Gerber Technology has created a PPE Task Force of experts to help companies increase their production or transition into producing PPE by sharing best practices, offering support, and providing resources such as pattern data, cut files, markers, and tech packs for masks, technical suits, gowns and caps as well as sign and graphics templates such as labels.

More than 300 manufacturers, including major global companies, rely on Gerber’s advanced software, hardware solutions and expertise to produce protective masks and other PPE. Over the last few months, Gerber has helped several customers transition into producing these much needed medical supplies, including Shanghai Challenge Textile Co., Ltd, BELLA + CANVAS, Hickey Freeman, Taglio Marchesini, and most recently Hardwire, LLC, where adding two new Gerber Paragon® multi-ply cutting solutions with CutWorks® software, as well as CutWorks® to their existing machines, is allowing them to produce tens of thousands of face shields per day.

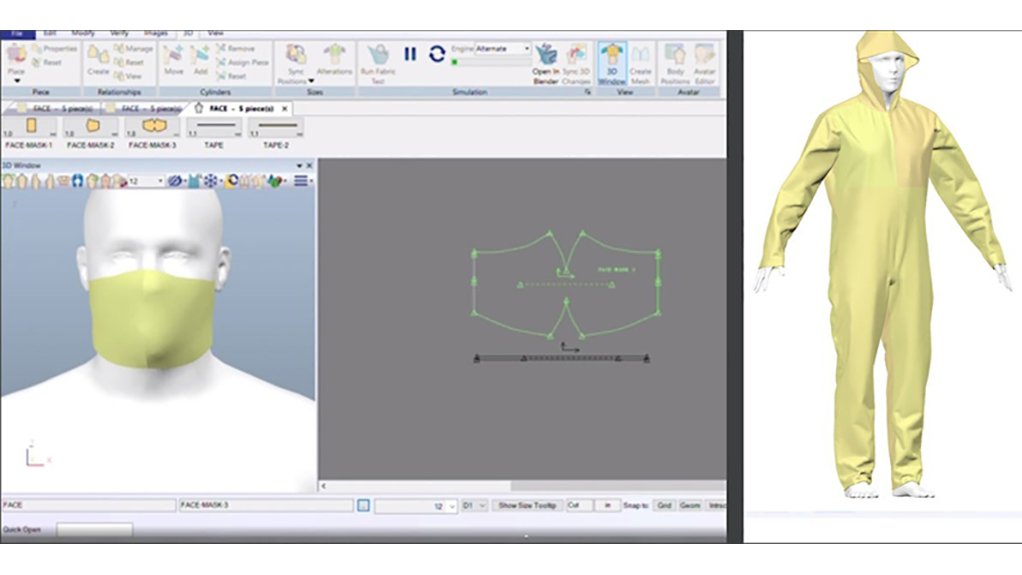

As the authorised distributor of Gerber Technology in South Africa for over 40 years, Intamarket Technology has been driving and supporting the Gerber Task Force initiative locally and has appealed to customers with sewing or cutting capacity to get involved by firstly considering excess or scrap fabric currently in stock that can be rolled out into healthcare garments such as gowns, masks, caps, aprons, surgical covers, uniforms, and other PPE desperately needed by hospitals and healthcare workers. Then, assisted by Intamarket’s knowledgeable applications specialists and through Gerber Technology portals, Accumark® 3D and Pattern Design Marking and Grading Software, patterns of the essential items are quickly made up. The response has been overwhelmingly positive and the Intamarket team has been assisting interested customers by offering guidance on how to optimise production, and providing the necessary resources and support for PPE manufacturing.

With warehouses in Durban, Sandton and Cape Town, and through the Intamarket Group’s Medical division, Intamed, the Company is geared to supply Hospital Groups and Healthcare Facilities nationwide. Intamarket Group’s Capital Hotels have partnered with Discovery Health to provide isolation facilities and Intamarket Graphics are supplying much needed Perspex and PET protective shields to companies.