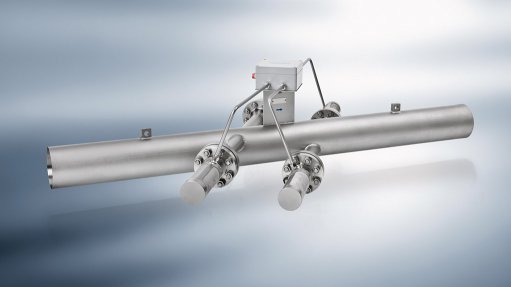

OPTISONIC 8300A two-beam ultrasonic flowmeter for high flow rates of superheated steam

Industrial process instrumentation manufacturer and solutions provider Krohne this year launched its new Optisonic 8300 ultrasonic flowmeter for high-temperature gas and steam onto the global market.

The new Optisonic 8300 ultrasonic flowmeter is a two-beam ultrasonic flowmeter for high flow rates of superheated steam, featuring 1% measuring accuracy, high repeatability and a large dynamic measuring range. Further, no parts on the flowmeter need to be maintained and no subsequent calibration is necessary for up to 20 years.

Owing to the increasing cost of steam, precise measurement is becoming progressively more important. With this in mind, the Optisonic 8300 flowmeter also features an integrated flow computer for steam mass flow calculation.

Krohne highlights the importance of considering energy loss, which can be caused by a pressure drop in the steam line. However, by supplying accurate measurement without a pressure drop, the Optisonic 8300 mitigates this situation.

Installing steam measurement systems is also a costly challenge, which is why the Optisonic 8300 was designed for long-term use. It can uphold its measuring accuracy without maintenance or the need for calibration for up to 20 years, while keeping operating costs at a bare minimum. The Optisonic 8300, therefore, does not require much attention.

However, if verification of the measuring accuracy should become necessary, it can be provided with flowmeter diagnostics, which eliminates the need to remove the flowmeter.

With nominal sizes ranging from DN 100 up to DN 1 000, or 4" to 40", the Optisonic 8300 is particularly suited to high flow rates. Pressure ratings of up to 200 bar and temperature ratings of up to 540 °C are also available, with higher requirements available on request.

In terms if applications, this product can be used in power plants, and in the chemicals and petrochemicals industries. Its applications include the allocation of used steam, the custody transfer of steam, turbine performance measurement and boiler performance measurement.

With temperature and pressure inputs, Krohne’s GFC 300 converter will calculate mass flow and enthalpy display, in addition to volumetric flow. This omits the need for an additional flow computer.

By means of temperature and pressure sensors connected to the device, the integrated flow computer can calculate steam mass flow. The Optisonic 8300 adds to Krohne’s range of ultrasonic process and custody transfer meters for liquids and gases, ranging from compressed air to liquid natural gas.

Founded in 1921 and headquartered in Duisburg, Germany, Krohne employs more than 3 500 people worldwide and is present on all continents.

Krohne is a full-services provider for process-measuring technology.