Gradually, more and more electromagnetic flowmeters are being discontinued and spare parts and support are no longer available. For you, this could mean: the malfunction of the electronics causes unwanted downtime, which results in significant consequences for your process and plant safety. IFC 300 not only safeguards your business and assets, it also makes your installation fit for the future, for example with additional features and the latest communication protocols.

Worried about process safety and expensive meter updates?

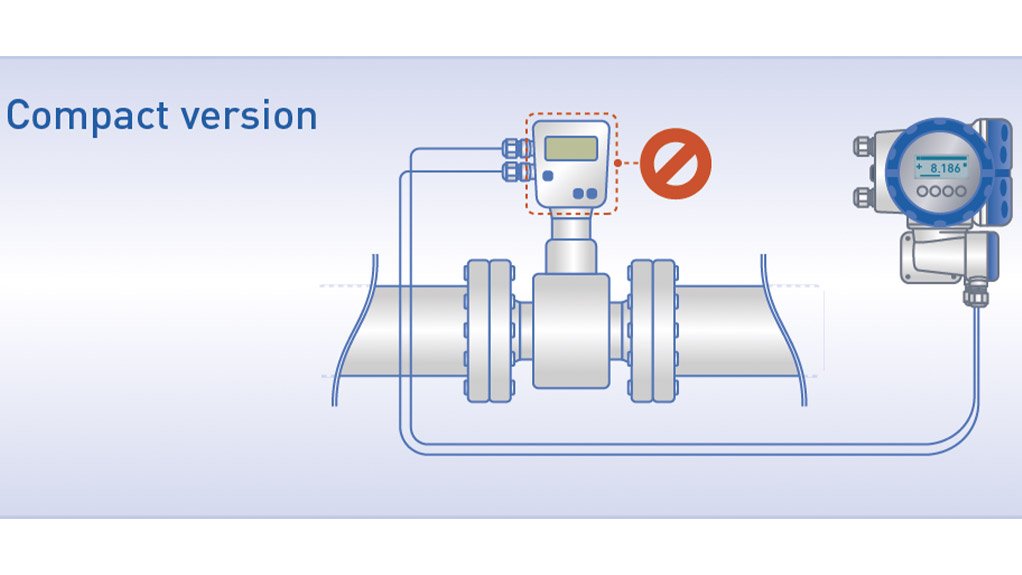

When making your product decisions, cost and performance must always be balanced. Not with the IFC 300! Because with it, you get more performance for lower costs. There is no need to buy an expensive new flow sensor and the process can continue

to run without time-consuming interruptions.

With its unrivalled measurement performance, the comprehensive diagnostics package and its numerous communication options (such as HART® PROFIBUS®, PROFINET®, FOUNDATIONTM fieldbus and Modbus), it ensures a high level of process reliability and is a real gain for your process.

Worried about extensive meter exchanges?

With the IFC 300, you are opting for a quick changeover to a converter that will accompany you for many years to come – always with the option of upgrading to other communication protocols at short notice and without complications.

KROHNE will check the compatibility of the used sensor and the installation situation in advance. You have to install the converter and assure that a reference flow is available during start-up for our replacement converter to be adjusted. Our KROHNE service engineers will support you in commissioning and start up (after mechanical and electrical installation) of the new converter.

Worried about insufficient safety-relevant data?

Particularly in the area of process safety, it is important to always be on the ball and to obtain corresponding data from the process that can be used to minimise risks. If this is not possible with the current transmitter, switching to the IFC 300 is the right decision.

IFC 300 offers detection of gas bubbles or solids, changing or too-low conductivity (e.g. during change of media or empty pipe)*, deposits or coating on the electrodes, electrode corrosion, too-high media or ambient temperature.*