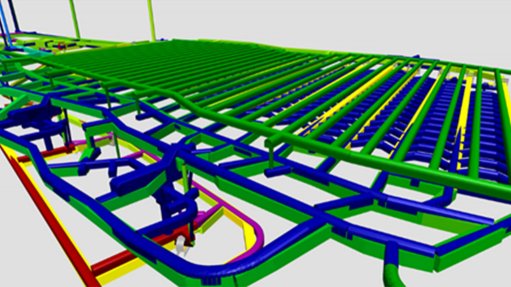

A graphic visualisation of ventilation networks from VUMA network

A newly updated interactive mine ventilation network simulation tool is now available free to the industry.

Mine ventilation, refrigeration and cooling engineering consultants, BBE Group, highlights that its VUMA-network software has been upgraded to 64-bit computing with a supercharged graphics engine. The solution is built on a Microsoft platform and has been enabled for global use, with support for different languages, such as Chinese, Polish and Spanish, and the integration of country-specific features and design criteria. In addition, the software is vendor agnostic, allowing it to integrate will all major industry software and solutions and users do not need to be BBE clients to access it.

“Intense temperatures, humidity, diesel fumes and gasses are health hazards for underground miners. This makes good ventilation non-negotiable,” says BBE Group ventilation engineer Miguel Coelho. “However, with so many complex factors impacting environmental conditions, dangerous shifts can be hard to predict. BBE’s VUMA-network software, with its ability to simulate multiple variables, addresses this issue. It also drives system optimisation and energy efficiency, a critical cost and operational factor for mines in South Africa. Making it available to industry at no cost puts everyone ahead.”

“With advanced simulation technology, mining and ventilation engineers can gain complete control over the crucial ventilation and cooling aspects of mining processes across a range of mining methods,” notes Coelho. “This is especially important as energy costs rise and safety regulations ramp up. With mine planning software becoming increasingly sophisticated, the kind of graphic ventilation network detail and troubleshooting that software like VUMA-network can provide is becoming invaluable.”

The tool simulates airflow, heat loads, gases (including radon, a radioactive gas released in uranium mining), dust and diesel particulate matter from diesel machinery, impacts of blast clearances and underground fires. Simulations are based on the specific conditions in a mine, such as the type and intensity of work, the performance of cooling infrastructure, use of machinery and mining methods employed.

The inputs may be collected from mine systems and sensors, imported directly from various mine-plan formats or defined by mining engineers. This facilitates planning and design of systems, energy optimisation, fault finding and troubleshooting, what-if scenario analyses, dust and/or gas tracing, refrigeration cooling system design and verification of environmental performance. Importantly, it allows engineers to identify hinge points where infrastructure can be improved and to test hypothesis before acting.