NEW AND IMPROVED The new set of features and tools also allows for easy adjustment of blast designs and rapid comparison of different scenarios

Commercial explosives and innovative blasting systems manufacturer Orica launched its SHOTPlus Underground solution two months ago.

SHOTPlus Underground is the company’s latest blast design and modelling software which specifically targets ‘advanced underground blast design’ and ‘complex blasting scenarios’.

The software has been fully rewritten and is now the premier blast design package for the underground mining sector, says Orica Global digital products senior manager Angelo Labriola.

He states that, since its original launch, the SHOTPlus software has, following successful trials by Orica’s technical services teams, grown to be the mining industry’s leading drill and blast software solution globally.

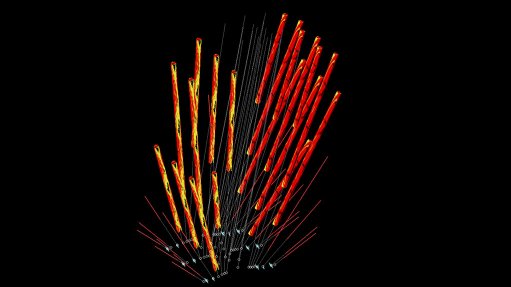

“Designing, analysing and visualising in three-dimensions (3D) has never been easier. Ring-to-ring and hole-to-hole interactions and overall blast dynamics are at your fingertips, allowing users to optimise and maximise output, benefits and results.”

Underground production blasting typically requires geometrically complex ring patterns, says Labriola. As such, optimising the explosives loading and initiation design and producing clear instructions to blasting crews requires a specialised software solution.

Labriola comments that SHOTPlus Underground is designed to meet the needs of underground mining applications, delivering an improved interactive 3D environment and enhanced visualisation as well as quality assurance/quality control tools to enable engineers to identify the most efficient blast design.

He notes that the new set of features and tools also allows for easy adjustment of blast designs and rapid comparison of different scenarios.

“The ability to seamlessly adjust, visualise and optimise underground blast loading designs and timing allows users to efficiently design blasts, irrespective of complexity.”

This also enables the necessary analysis to optimise the performance of blast designs with Orica’s electronic initiation systems, dramatically cutting down the time required to produce loading and timing instructions for blast crews, says Labriola.

Direct integration with Orica’s electronic initiation systems ensures that the blast design process flows seamlessly, with Orica’s product suite delivering enhanced accuracy and efficiency while ensuring the integrity and safety of the process, he concludes.