Traditionally, gaskets must be fastened tightly to achieve the proper, required seal. However, tightly fastening a gasket accelerates wear and tear, which compromises the seal's original function. In case of fire, the release of gas or the development of smoke, the consequences can be catastrophic.

To prevent this, Beele Engineering has developed a new type of gasket based on the high-quality NOFIRNO rubber. These gaskets can be used in environments with temperatures ranging from -50 °C to +180 °C.

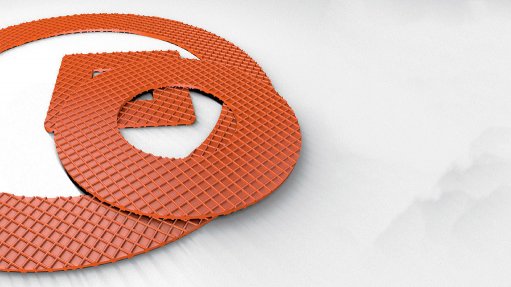

The new Beele Engineering gaskets stand out due to their exceptional profile and high-quality rubber. This ensures that with modest press-on forces of approx 6‑8 Nm, an optimal, lasting seal is created. Tests up to a maximum of 15 bar were conducted. Once tightened, the gaskets provide a durable seal.

That means that the regular tightening of bolts has become superfluous. Due to the NOFIRNO rubber's high restorative capacity, the gaskets can be reused after the flange has been unscrewed and is then tightened down again.

The NOFIRNO gaskets are available in a wide range of versions and dimensions. For example, there are round, square and rectangular gaskets, as well as 1,000 x 1,000 mm gasket sheets, from which non-standard shapes can be cut. The gaskets come in a thickness of 5 or 10 mm.

The gaskets are approved for use in drinking water applications. Due to the NOFIRNO rubber's fire-resistant, smoke, gas and watertight qualities, the gaskets can also be used in environments where fire or water can have or has free range. For example, NOFIRNO gaskets are currently being used in fire valves.

Another important feature for outside applications is that the NOFIRNO rubber is UV, ozone and weather-resistant.